Double-iron-core direct-current-component-resistant current transformer

A technology of current transformers and transformers, applied in the direction of inductors, transformer/inductor cores, circuits, etc., can solve problems such as inability to induce secondary side windings, safety accidents, control circuit errors, etc., and achieve light weight, Guaranteed accuracy and safety, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

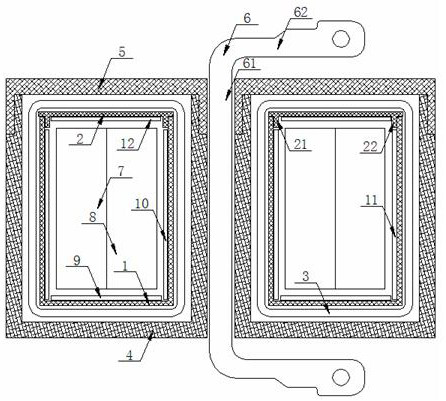

[0013] refer to figure 1 , figure 1 It is a structural schematic diagram of a specific embodiment of the present invention.

[0014] Such as figure 1 As shown, a dual-core anti-DC component current transformer includes a ring-shaped transformer iron-based double magnetic core, and a ring-shaped transformer core insulating shell 1 set outside the transformer iron-based double magnetic core , the transformer core insulation cover plate 2 matched with the transformer core insulation shell 1, the secondary side of the transformer wound on the outer side of the transformer core insulation shell 1 and the transformer core insulation cover plate 2 Winding 3, a transformer packaging shell 4 of annular structure set on the outer side of the transformer secondary side winding 3, a transformer packaging cover plate 5 matching the transformer packaging shell 4, the center of the transformer packaging shell 4 The through hole is also provided with a primary side terminal 6 of the transf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com