Integrally sealed device for cleaning dust on surface of cooling fan in computer

An internal cooling and overall sealing technology, applied in the computer field, can solve the problem of dust adhering to the fan blades, and achieve the effect of increasing the efficiency of heat dissipation and improving the heat dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

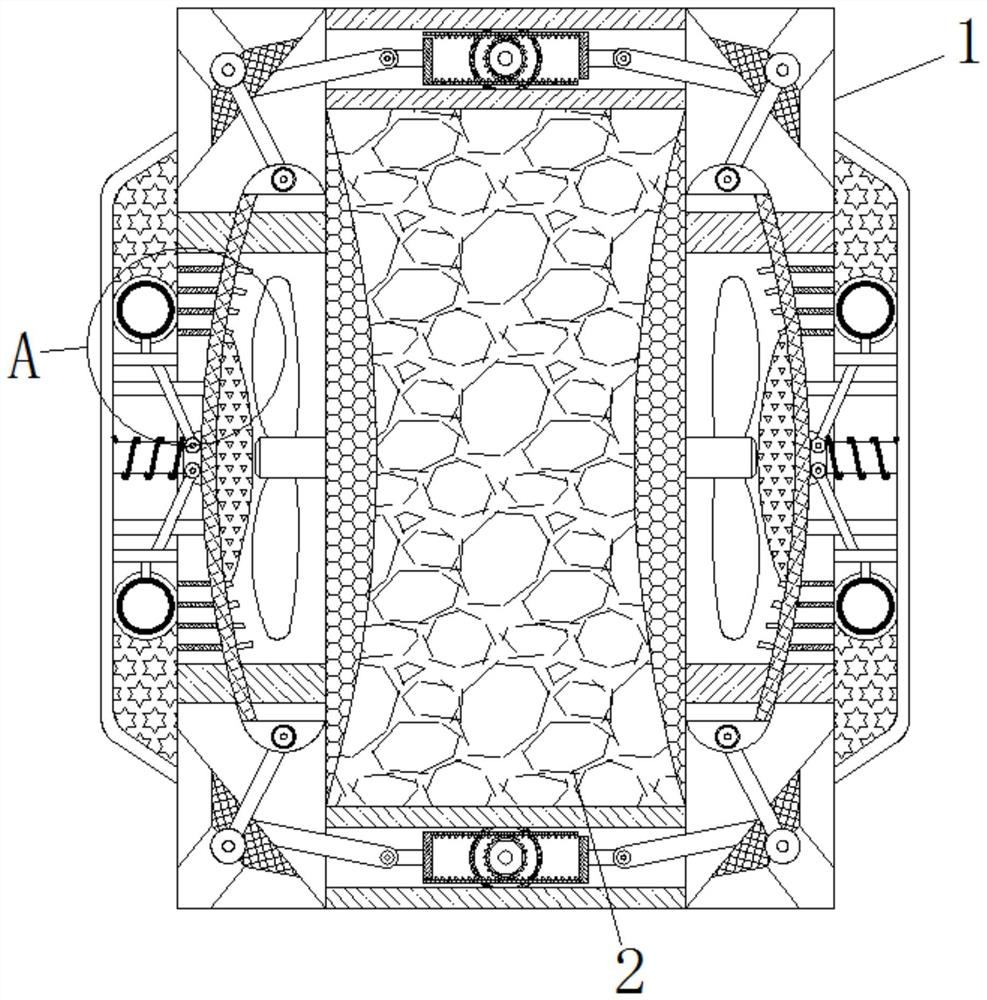

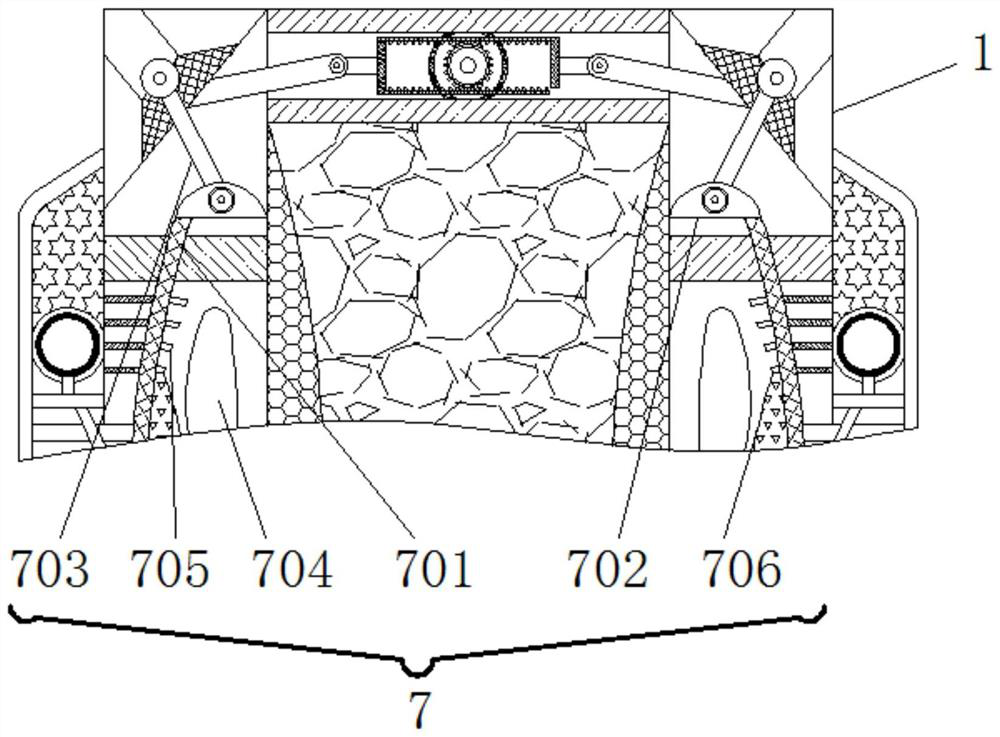

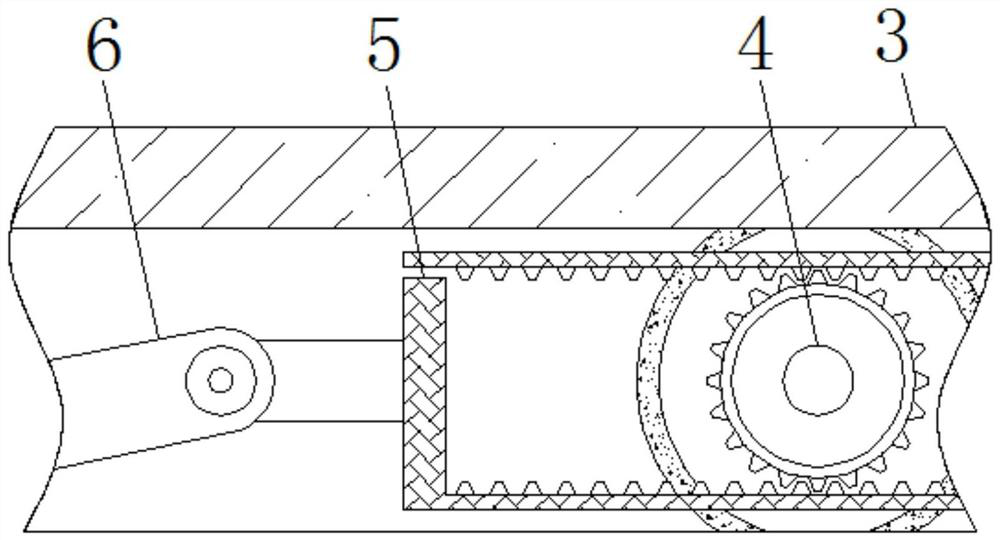

[0027] see Figure 1-3 , an integrally sealed computer internal cooling fan surface dust cleaning device, including a frame 1, the inside of the frame 1 is provided with a groove body 2, the upper and lower ends of the frame 1 are fixedly installed with a fixed plate 3, and the internal rotation of the fixed plate 3 The adjustment wheel 4 is connected, the upper and lower ends of the adjustment wheel 4 are meshed with symmetrically distributed moving plates 5, the opposite sides of the moving plates 5 are movably hinged with linkage rods 6, and the left and right ends of the frame 1 are fixedly installed with heat dissipation Mechanism 7, radiating mechanism 7 comprises: arc plate 701, and the upper and lower ends of arc plate 701 are all movably installed with movable block 702, and connecting rod 703 is articulated on the opposite side of movable block 702, and arc plate 701 is close to groove The blade body 704 is rotatably connected to the end surface of the body 2, and th...

Embodiment 2

[0029] see Figure 1-4 , an integrally sealed computer internal cooling fan surface dust cleaning device, including a frame 1, the inside of the frame 1 is provided with a groove body 2, the upper and lower ends of the frame 1 are fixedly installed with a fixed plate 3, and the internal rotation of the fixed plate 3 The adjustment wheel 4 is connected, the upper and lower ends of the adjustment wheel 4 are meshed with symmetrically distributed moving plates 5, the opposite sides of the moving plates 5 are movably hinged with linkage rods 6, and the left and right ends of the frame 1 are fixedly installed with heat dissipation Mechanism 7, the cleaning mechanism 8 that is symmetrically distributed is fixedly installed on the phase back of heat dissipation mechanism 7, and cleaning mechanism 8 comprises: connecting frame 801, and the upper and lower ends of connecting frame 801 inside are all fixedly installed with slide plate 802, and the phase of slide plate 802 A connecting b...

Embodiment 3

[0031] see Figure 1-4, an integrally sealed computer internal cooling fan surface dust cleaning device, including a frame 1, the inside of the frame 1 is provided with a groove body 2, the upper and lower ends of the frame 1 are fixedly installed with a fixed plate 3, and the internal rotation of the fixed plate 3 The adjustment wheel 4 is connected, the upper and lower ends of the adjustment wheel 4 are meshed with symmetrically distributed moving plates 5, the opposite sides of the moving plates 5 are movably hinged with linkage rods 6, and the left and right ends of the frame 1 are fixedly installed with heat dissipation Mechanism 7, heat dissipation mechanism 7 includes: arc plate 701, arc plate 701 is made of elastic material, the connection relationship between cleaning rod 705, protruding bag 706 and fan blade body 704 is close contact connection, arc plate 701 Movable blocks 702 are movably installed at the upper and lower ends of the upper and lower ends, and connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com