Conveying and folding compound machine for corrugated sheets of transformer

A corrugated sheet and transformer technology is applied in the field of transformer corrugated sheet conveying and folding compound machines, which can solve the problems of low production efficiency and achieve the effects of continuous feeding and reliable folding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

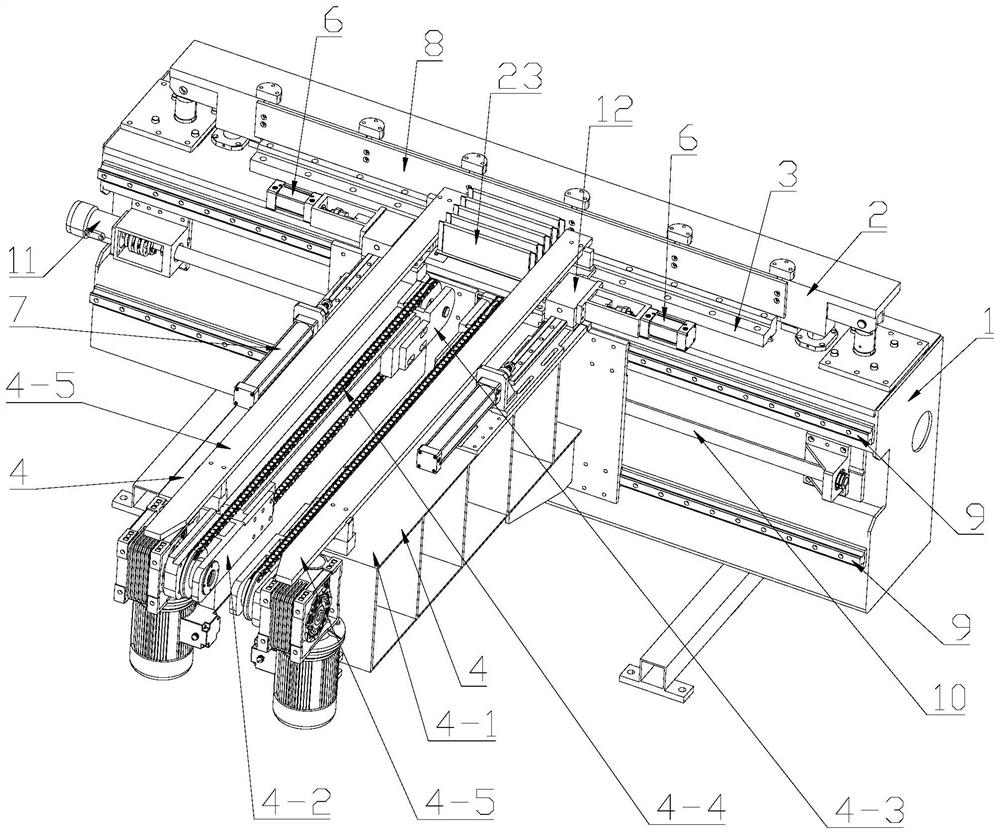

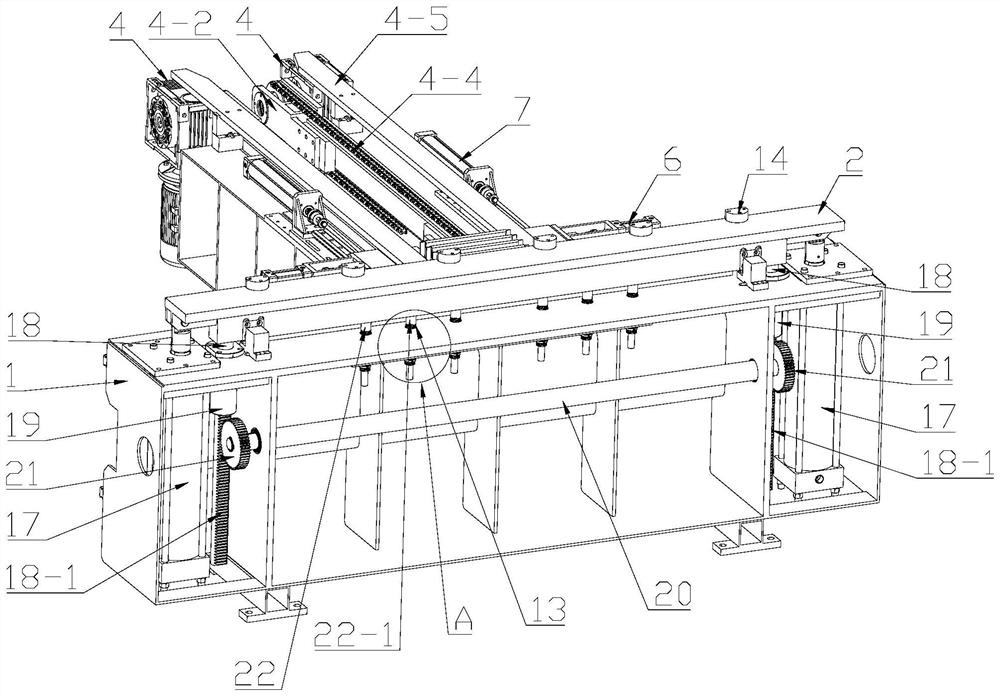

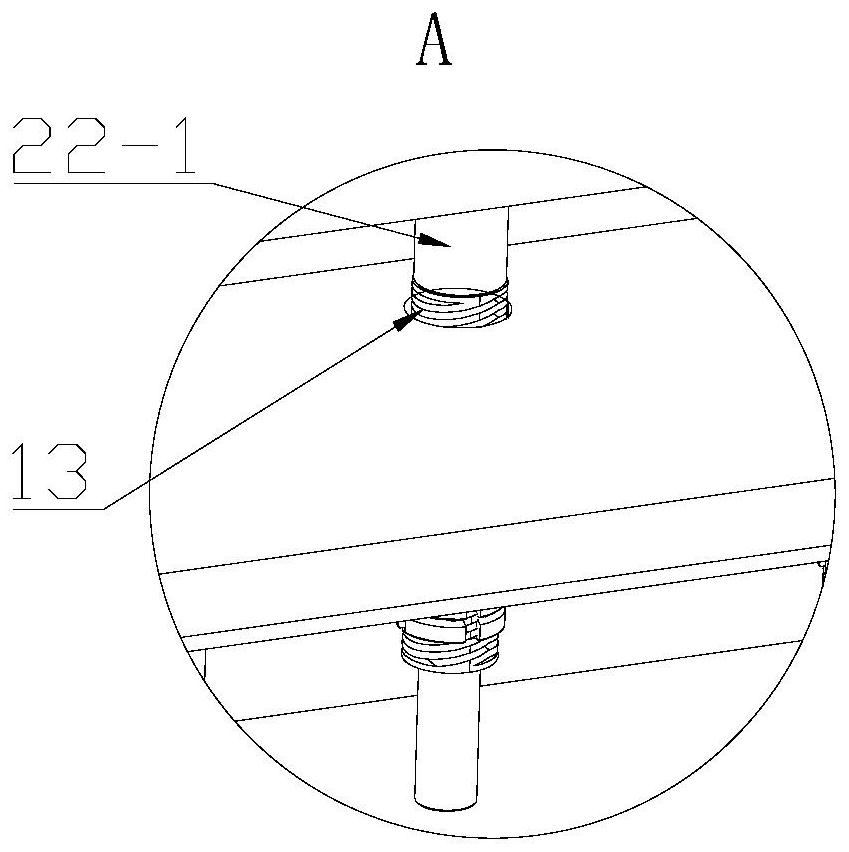

[0023] Such as Figure 1-7 As shown, a transformer corrugated sheet conveying and folding compound machine includes a folding mechanism and a conveying mechanism. The folding mechanism includes a base 1, a fixed-length structure, and an upper mold 2 and a lower mold for folding installed on the base 1 3. The lower mold 3 is fixed, and the fixed-length structure is located in front of the lower mold 3. The upper mold 2 presses down to fold the edge. The conveying mechanism includes two conveying arm mechanisms 4 on the left and right, and the two conveying arm mechanisms 4 are installed on the front end structure. The rear side of the base 1 and the front part of the delivery arm mechanism 4 have a hemming correction mechanism. The hemming correction mechanism includes a correction lock tongue mechanism and a forward push mechanism 7. The correction lock tongue mechanism can be slidably set in the conveying direction through the guide rail mechanism, and the correction lock The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com