Battery electrode plate processing die

A technology for processing battery electrodes and sheets, which is applied in the fields of electrode forming, electrode manufacturing, and pushing out equipment, etc. It can solve the problems of large manpower and time consumption, inconvenience for workers to take, and affect the processing efficiency of battery electrode sheets, so as to achieve convenience and efficiency. The effect of improving and reducing the probability of extrusion damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

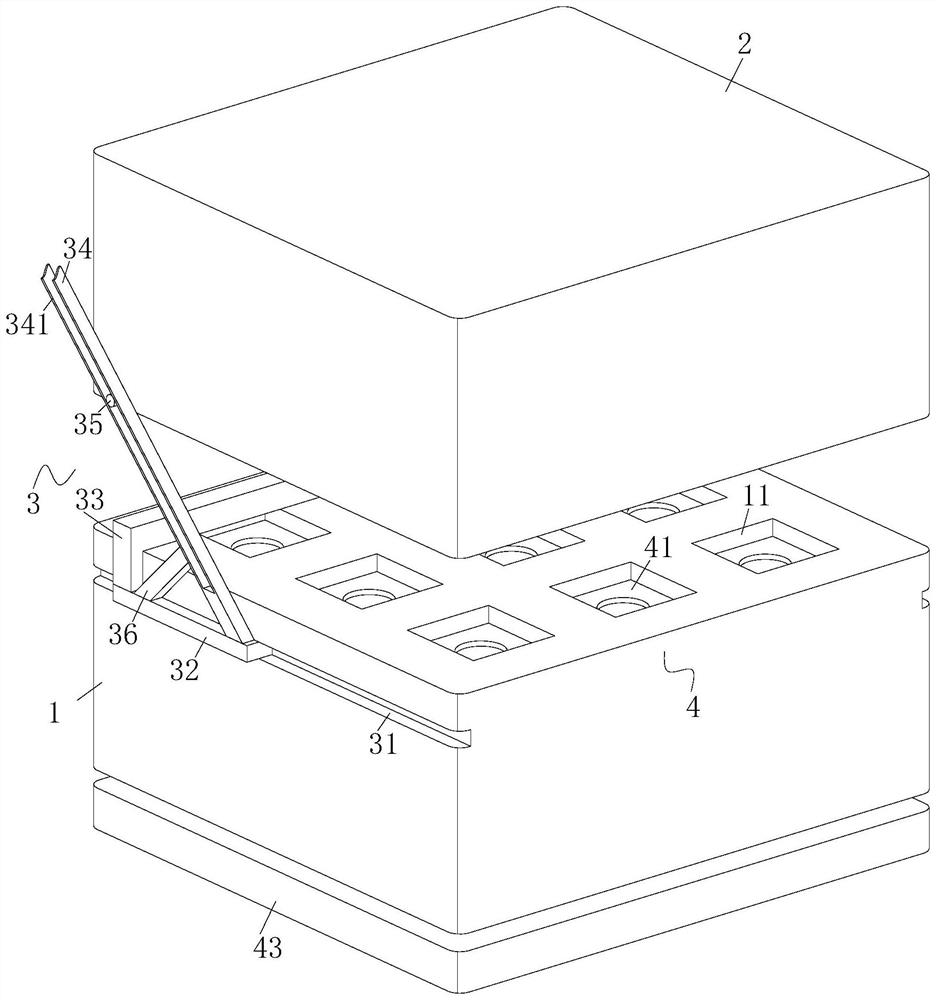

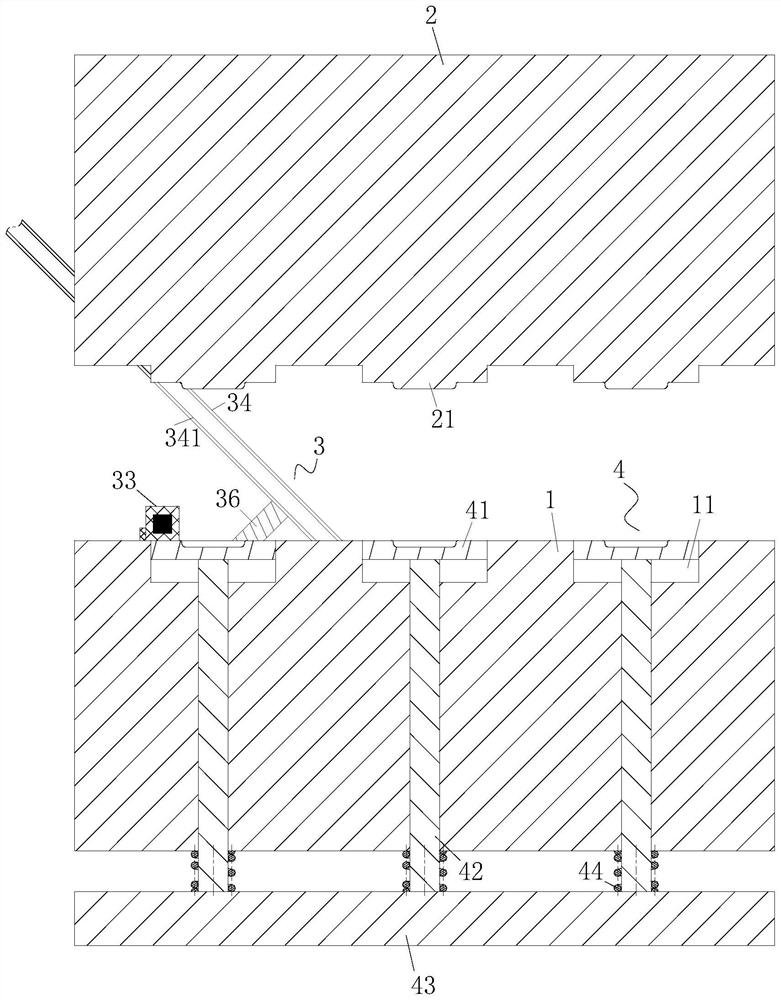

[0048] As an embodiment of the present invention, the unloading assembly 3 includes

[0049] A chute 31, the chute 31 is provided on one of the side walls of the lower mold 1, and the chute 31 penetrates from one side of the lower mold 1 to the other side;

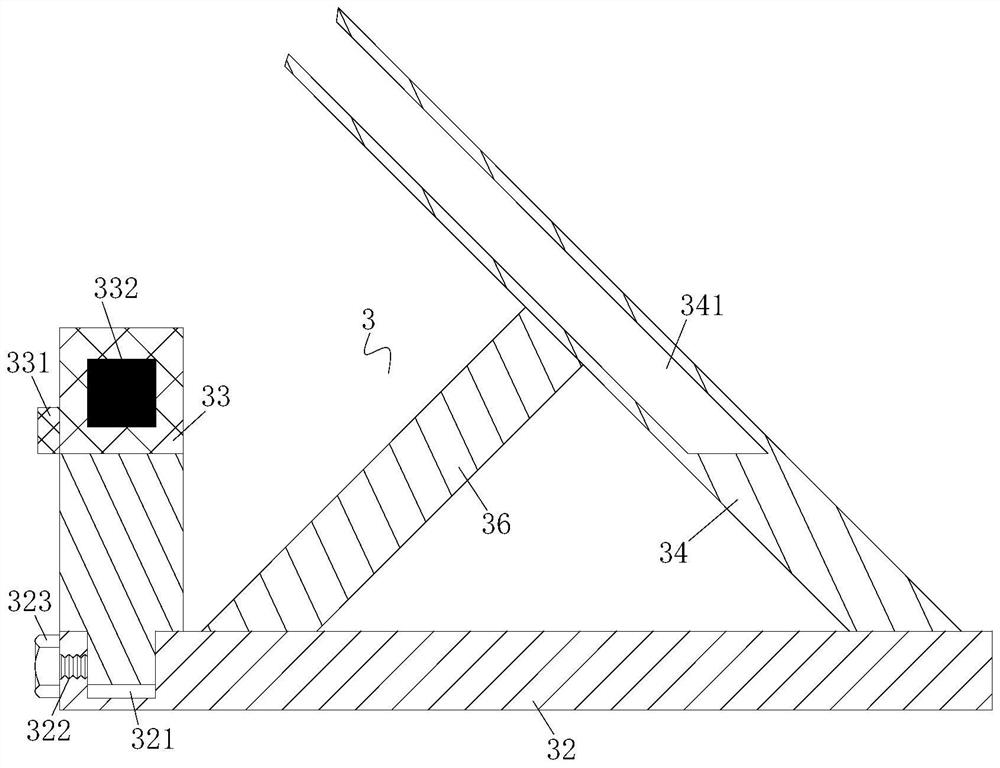

[0050] A slide bar 32; the slide bar 32 is slidably connected with the chute 31;

[0051] Scraper 33; the lower end surface of the scraper 33 is at the same level as the upper end surface of the lower mold 1, and the scraper 33 is perpendicular to the slide bar 32, and one end of the scraper 33 is connected to the slide bar 32 The end of is detachably connected, and the other end extends to the other side of the lower mold 1;

[0052] The connecting rod 34; the connecting rod 34 is arranged obliquely close to the scraping bar 33, and the lower end is fixedly connected with the other end of the sliding bar 32; the side of the connecting rod 34 close to the lower mold 1 is provided with a guide groove 341;

[0053]Guide b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com