Disc buckle type cantilever support system

A support system and cantilever frame technology, which are applied to the scaffolding supported by the building structure, the accessories of the scaffolding, the support of the building structure, etc., can solve the problems of difficult installation and adjustment, affecting the installation of the frame structure, complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

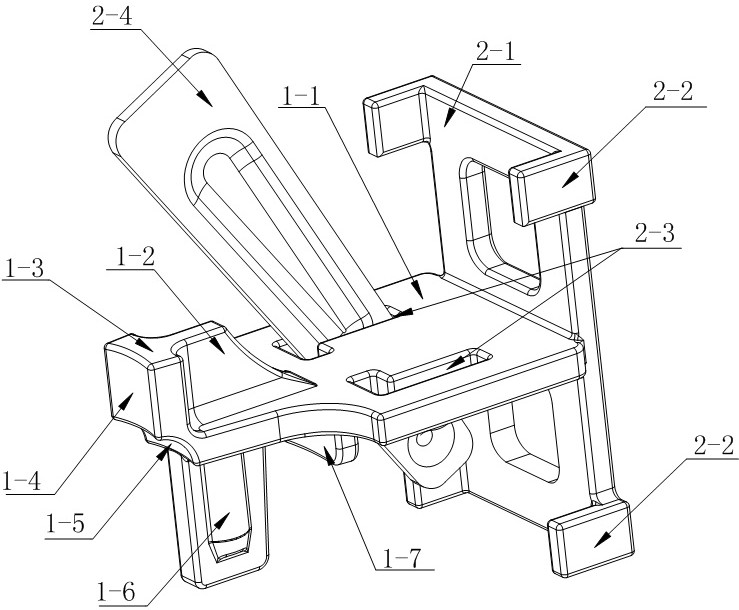

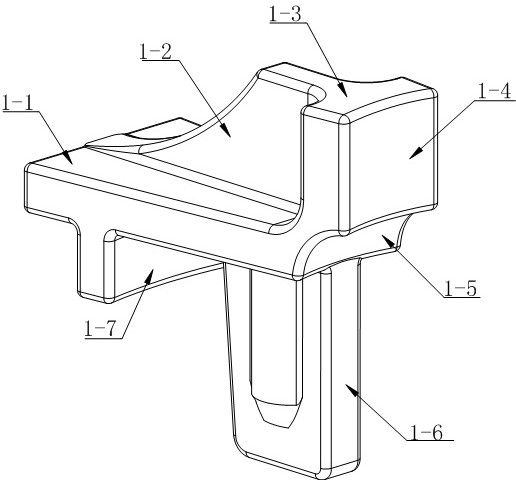

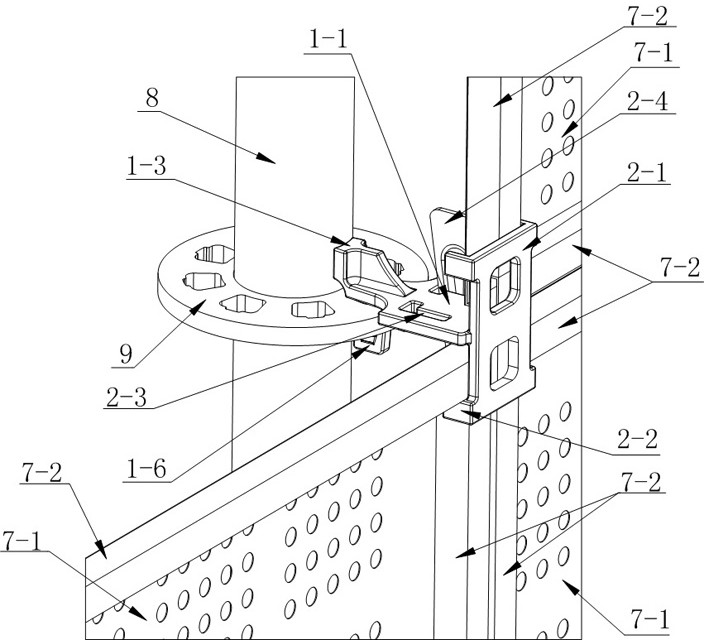

[0042] The coiled cantilever bracket of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments of the present invention.

[0043] Assembly of wedge pins:

[0044] Insert the wedge pin 2-4, wedge pin 3-4, and the narrow end of wedge pin 5-4 into the L-shaped pin hole 2-3, inverted Ω-shaped pin hole 3-3, and inverted Ω-shaped pin hole 5-3 respectively and keep The upright face is facing the front baffle 2-1, the front baffle 3-1, the front baffle: 5-1, and a bulge is riveted or punched out at the end of the small head, which prevents the wedge pin 2-4 , wedge pin 3-4, wedge pin 5-4 fall off from the pin hole.

[0045] The installation process of one-to-four four-piece suspension frame 2:

[0046] Such as figure 1 , figure 2 , image 3 As shown, first insert the conjoined pins 1-6 of the integrated lock head 1 of the one-to-four conjoined suspension frame 2 into the jack in the connecting plate 9 of the bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com