Device and method for preparing ice crystals in normal-temperature environment

An ice crystal and environment technology, used in the manufacture of ice, measurement devices, and engine testing, can solve the problems of high cost, single shape and particle size of ice crystals, and difficulty in simulating meteorological conditions, and achieve the effect of various particle sizes and cost savings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

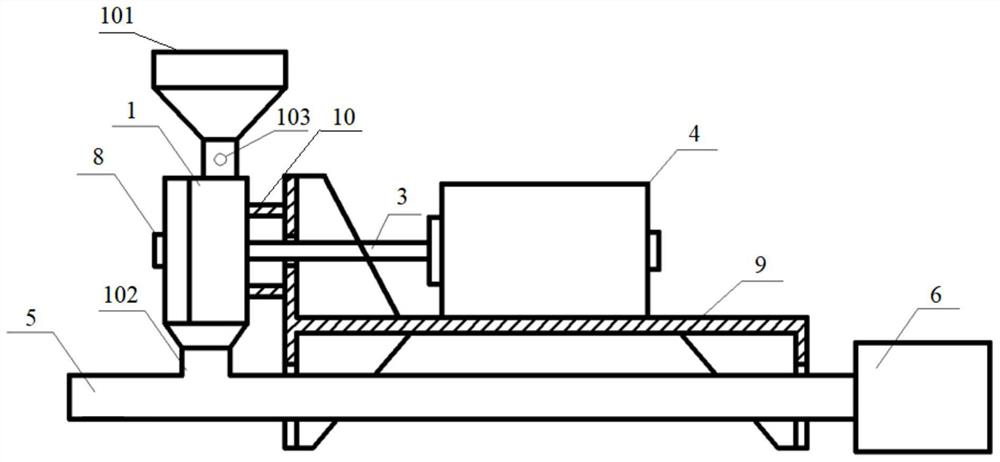

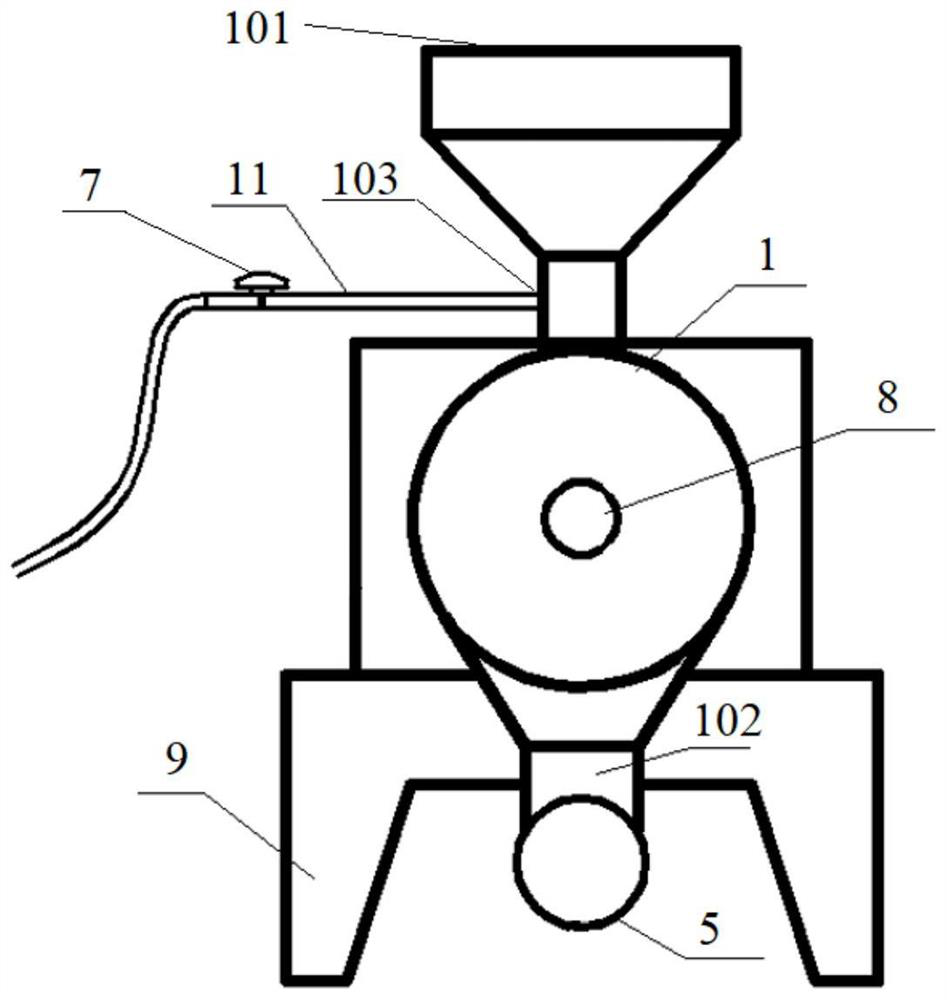

[0034] This embodiment discloses a device for preparing ice crystals under normal temperature environment, such as figure 1 and figure 2 As shown, the device includes a grinding chamber 1 , a grinding disc 2 , a rotating shaft 3 , a motor 4 , an ice blowing pipeline 5 , a fan 6 , a thermometer and a support table 9 .

[0035] The grinding chamber 1 is provided with an ice loading opening 101, an ice dropping opening 102 and solid CO 2 air inlet 103 . The ice loading opening 101 is located at the top of the grinding chamber 1 . The ice drop opening 102 is arranged at the bottom of the grinding chamber 1, and the ice drop opening 102 is connected with the ice blowing pipeline 5, and the fan 6 is arranged at the end of the ice blowing pipeline 5 for blowing out the ice crystals falling into the ice blowing pipeline 5. The ice-blowing pipeline 5 is a three-way transparent PVC hard pipe.

[0036] Solid CO 2 The air inlet 103 is used to feed solid CO into the grinding chamber ...

Embodiment 2

[0044]This embodiment discloses a method for preparing ice crystals under normal temperature environment, which is prepared by using the device for preparing ice crystals under normal temperature environment described in Example 1. The specific preparation method includes:

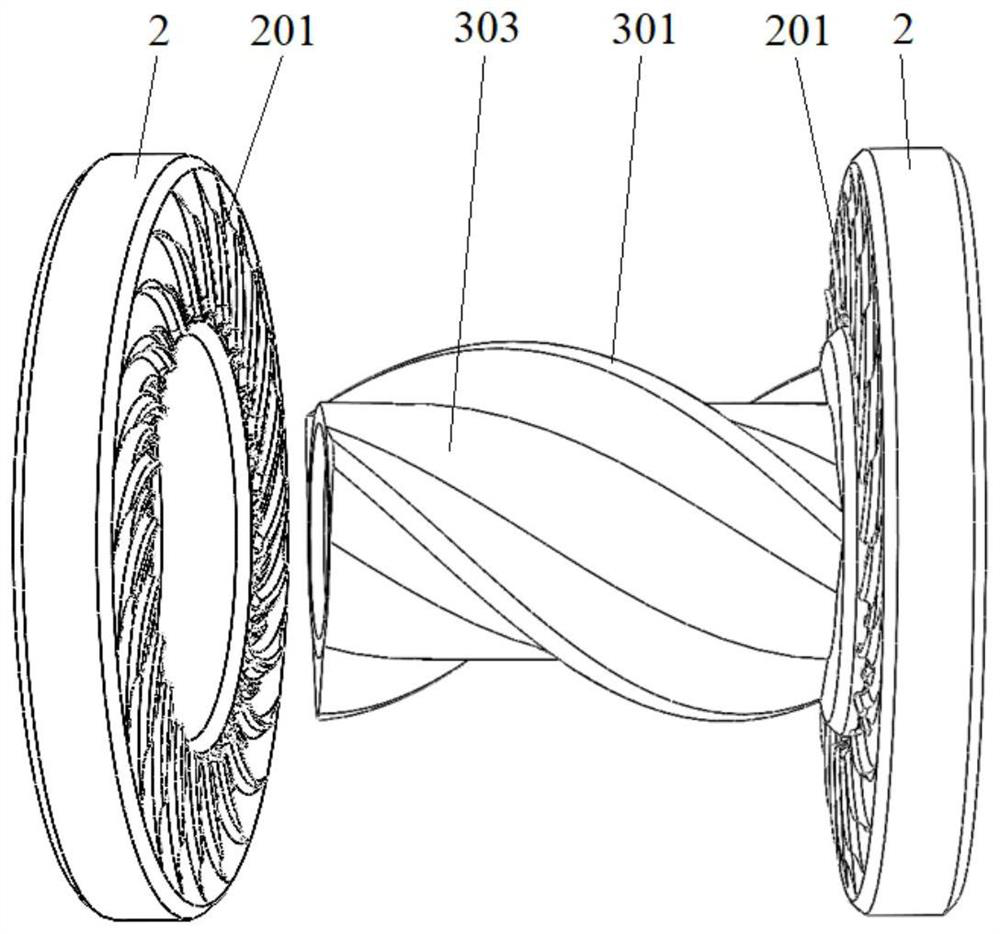

[0045] Step 1, start the motor 4 and the fan 6 to run, the grinding disc 2 starts to rotate, and the rotating speed of the grinding disc 2 is 1400 rpm.

[0046] Adjust the distance between two adjacent grinding discs 2 according to the required ice crystal size. In this embodiment, the adjustment button 8 on the grinding chamber 1 can realize rapid adjustment. In this embodiment, the distance between the two grinding discs 2 is very small. The teeth on the two grinding discs 2 can touch each other.

[0047] Step 2, open the CO 2 The cylinder valve feeds CO into the grinding chamber 1 2 At the same time, use a thermometer to detect the temperature in the grinding chamber 1. When the temperature reaches -2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com