Electromagnetic relay

A technology for electromagnetic relays and supporting walls, applied in electromagnetic relays, relays, detailed information of electromagnetic relays, etc., can solve the problems of resin chips, terminal position deviation, base cracks, etc., and achieve crack suppression, bounce suppression, high heat resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

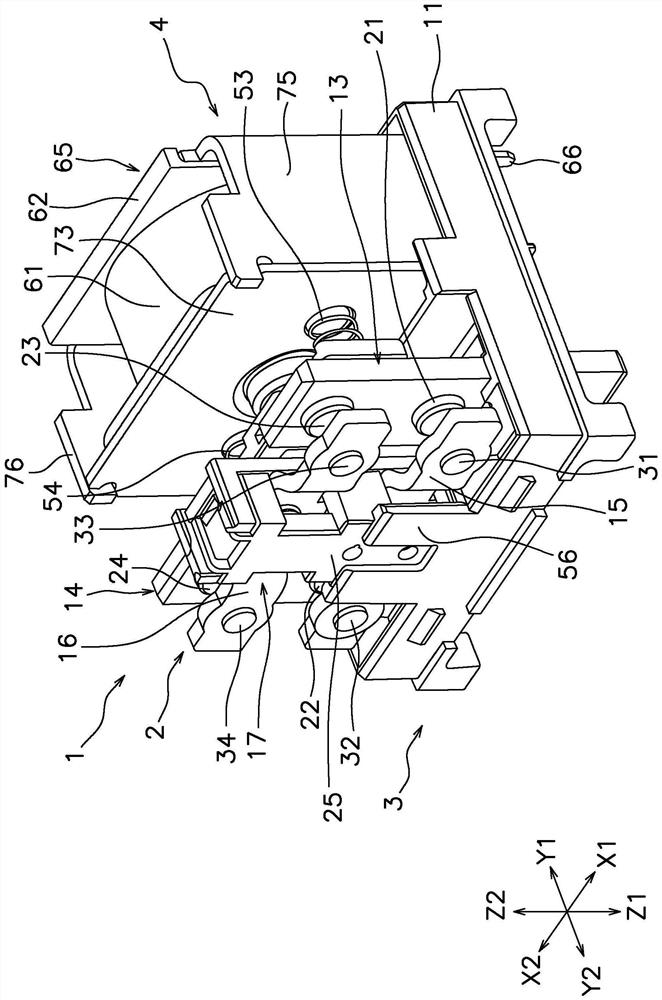

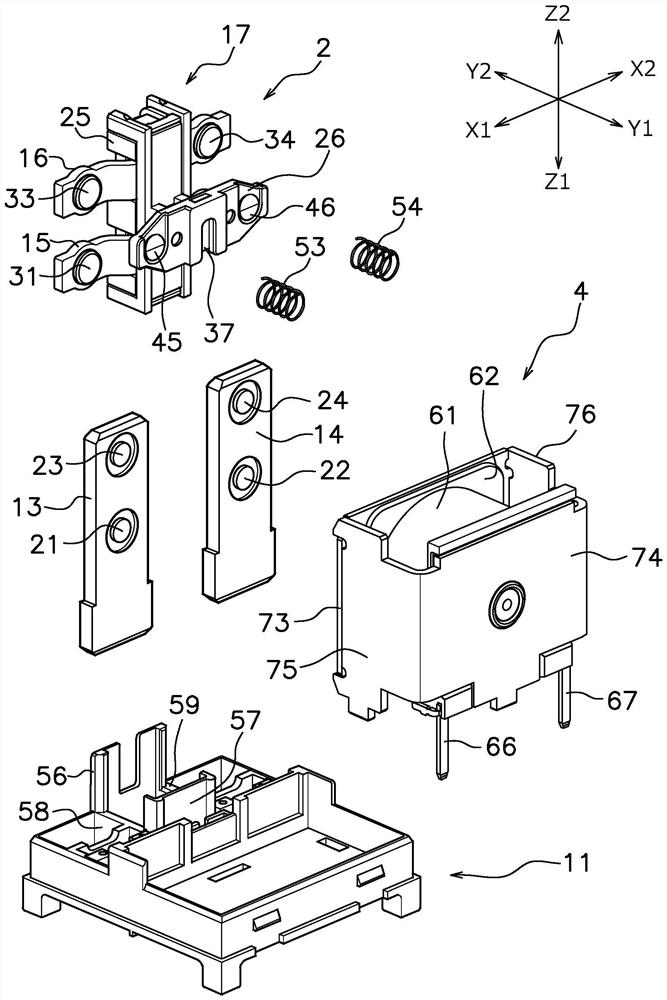

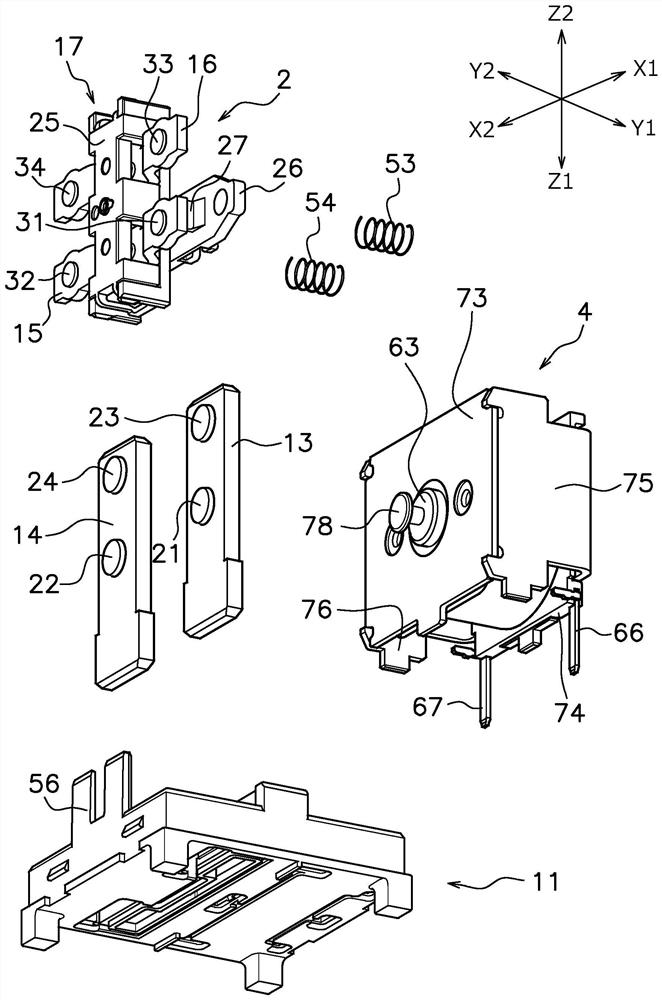

[0031] Hereinafter, electromagnetic relay 1 according to the embodiment will be described with reference to the drawings. figure 1 It is a perspective view of the electromagnetic relay 1 of embodiment. figure 2 and image 3 It is an exploded perspective view of the electromagnetic relay 1. Figure 4 It is a vertical sectional view of the electromagnetic relay 1 . Figure 5 and Image 6 is a plan view of the electromagnetic relay 1 .

[0032] The electromagnetic relay 1 includes a contact block 2 , a case 3 , a coil block 4 , a first fixed terminal 13 , and a second fixed terminal 14 . The contact block 2 and the coil block 4 are arranged in the housing 3 . The casing 3 includes a base 11 and a casing 12 . The base 11 and the case 12 are made of resin, for example. also, figure 1 The housing 12 is omitted. The base 11 supports the first fixed terminal 13 , the second fixed terminal 14 , the contact block 2 and the coil block 4 .

[0033] In this embodiment, the movem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com