Lithium battery and formation method thereof

A formation method and lithium battery technology, applied in the direction of lithium storage batteries, secondary batteries, electrochemical generators, etc., can solve the problems of long formation time and too high requirements for battery model limitations, and achieve short formation time, good formation effect, The effect of reducing the cost of formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0035] In order to solve the problems existing in the existing lithium battery formation method, the present invention provides a lithium battery formation method with accurate and reliable measurement, simple operation and low investment cost.

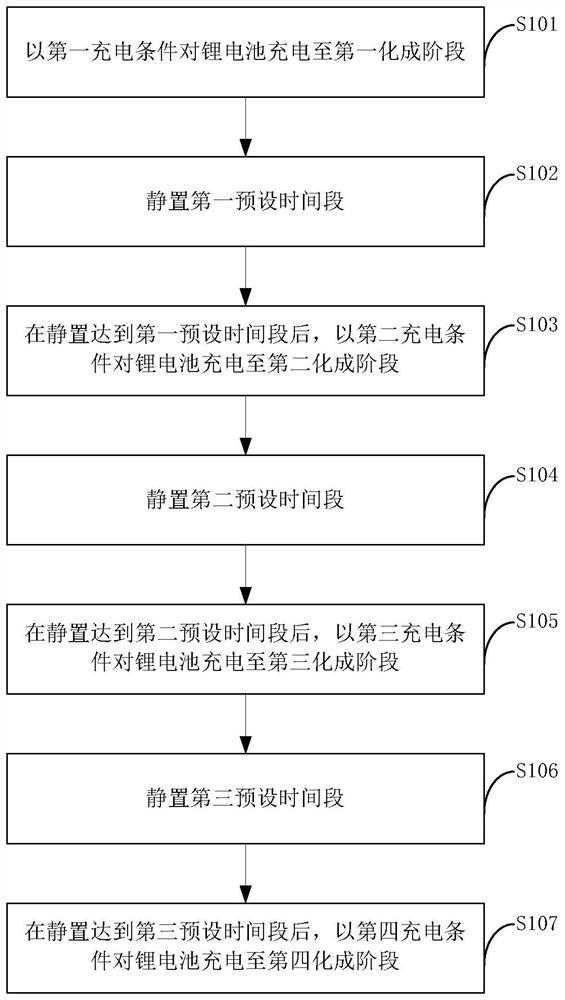

[0036] refer to figure 1 , is a schematic flow chart of an alternative embodiment of the lithium battery formation method provided by the present invention.

[0037] Specifically, such as figure 1 Shown, this lithium battery formation method comprises the following steps:

[0038] Step S101 , charging the lithium battery to the first formation stage under the first charging condition.

[0039] Step S102, standing still for a first preset time period.

[0040] Step S103 , af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com