Warm-keeping down jacket fabric pasting device

A technology of down jacket fabric and patch device, which is applied to clothing, apparel, tools for sewing clothes, etc., can solve problems such as unfavorable processing and sales, weak fabric patches, and folds of down fabrics, so as to reduce the distance that must be moved, Ease of operation and improved speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

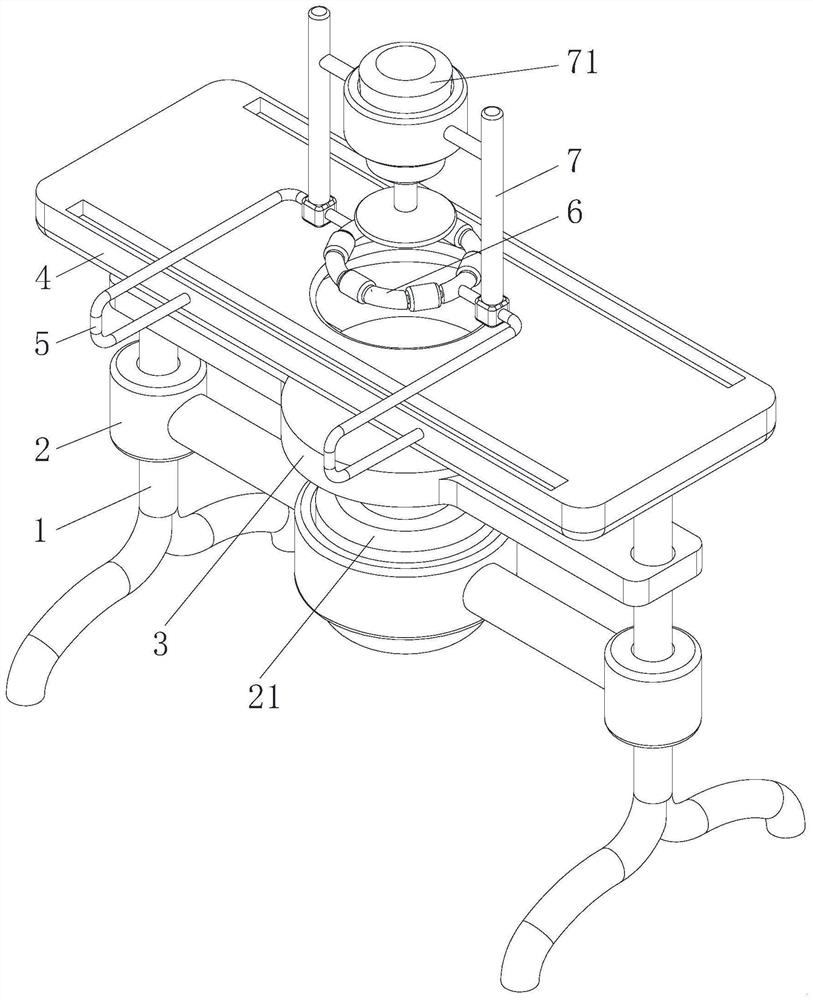

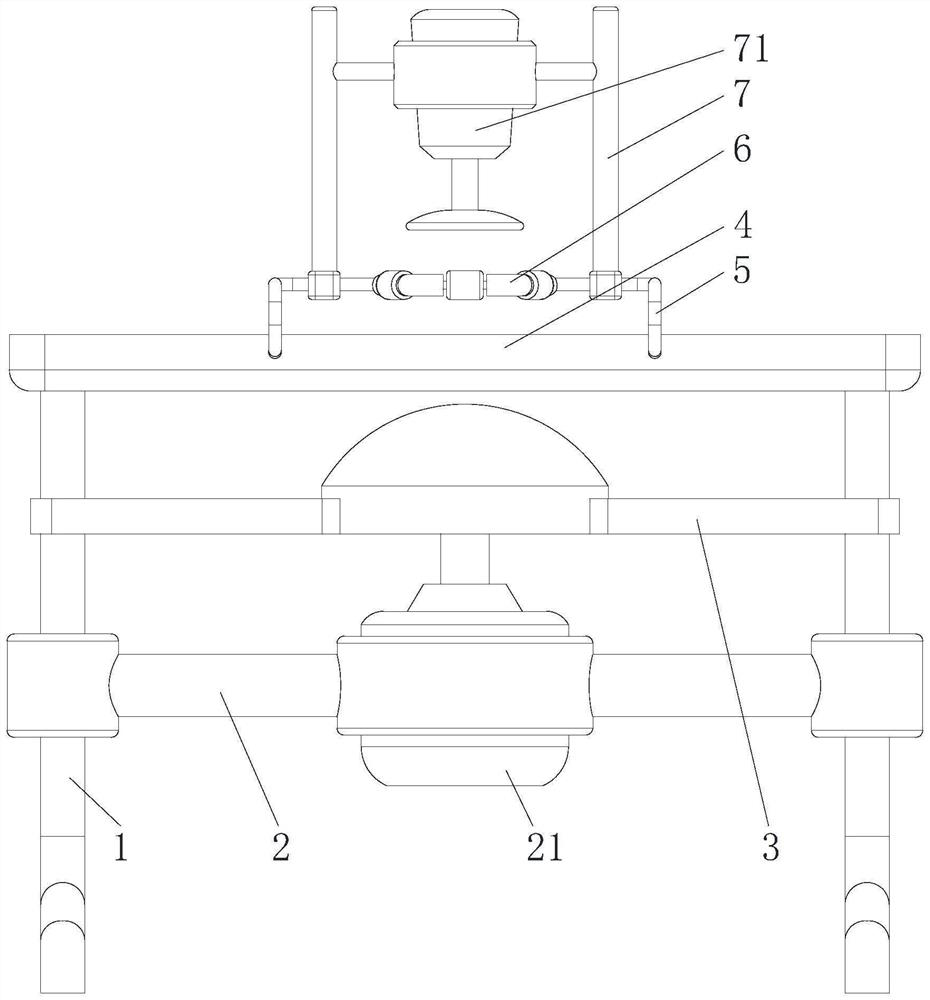

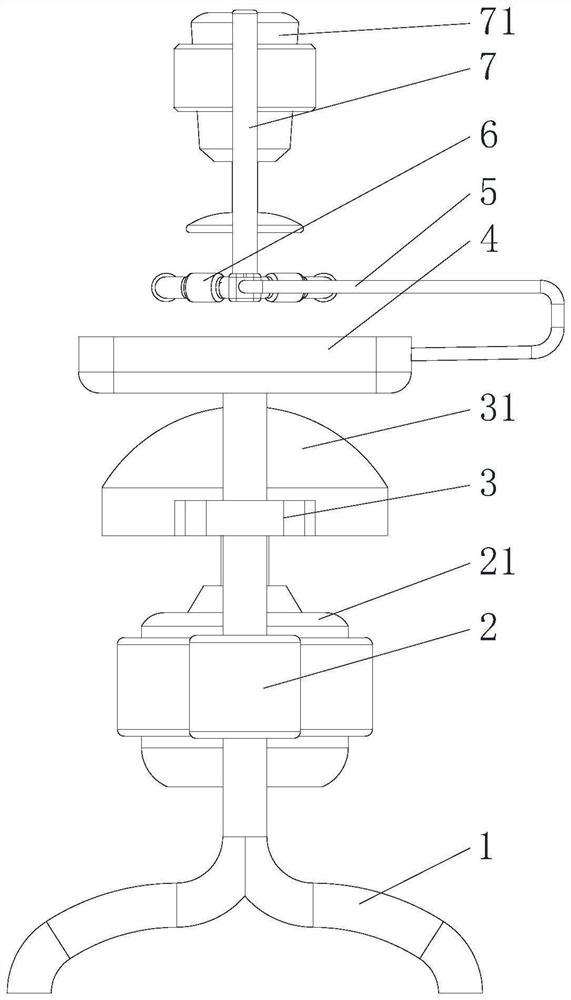

[0024] see Figure 1~4 , in an embodiment of the present invention, a warm down jacket fabric patching device includes a chassis 1, a jacking fixture 2 is provided on the chassis 1, a jacking motor 21 is provided on the jacking fixture 2, and a jacking motor 21 is provided on the chassis 1. There is a top plate 3, the bottom of the top plate 3 is connected to the output end of the jacking motor 21, the top of the top plate 3 is provided with a spherical protrusion 31, and the spherical protrusion 31 is made of rubber material, and the top of the bottom frame 1 is provided with a workbench 4, on the workbench 4 Be provided with the positioning hole 41 that cooperates with spherical projection 31, be provided with moving groove 42 symmetrically on the workbench 4, be provided with conveyer belt in the moving groove 42, be provided with on the workbench 4 and match the fixing frame 5, be provided with on the matching fixing frame 5 There is a matching ring 6, the center of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com