Auxiliary ash removal device for cutting of aluminum plate

A cleaning device and plate technology, which is applied to metal processing equipment, maintenance and safety accessories, metal processing machinery parts, etc., can solve the problems that the plate does not meet the production requirements, consumes a lot of time and energy, and avoids the reduction of work efficiency. The effect of improving safety and good experience effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

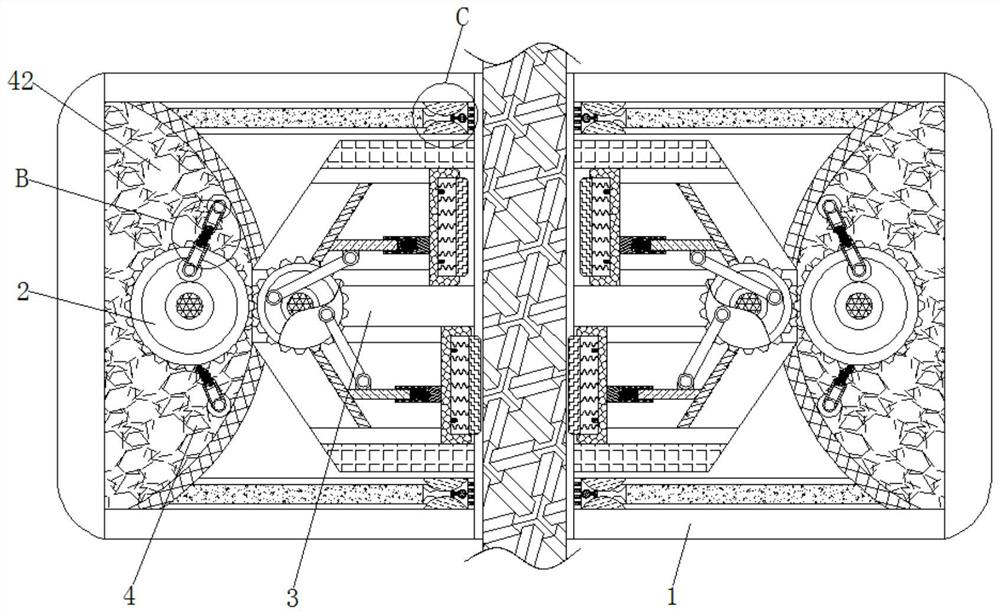

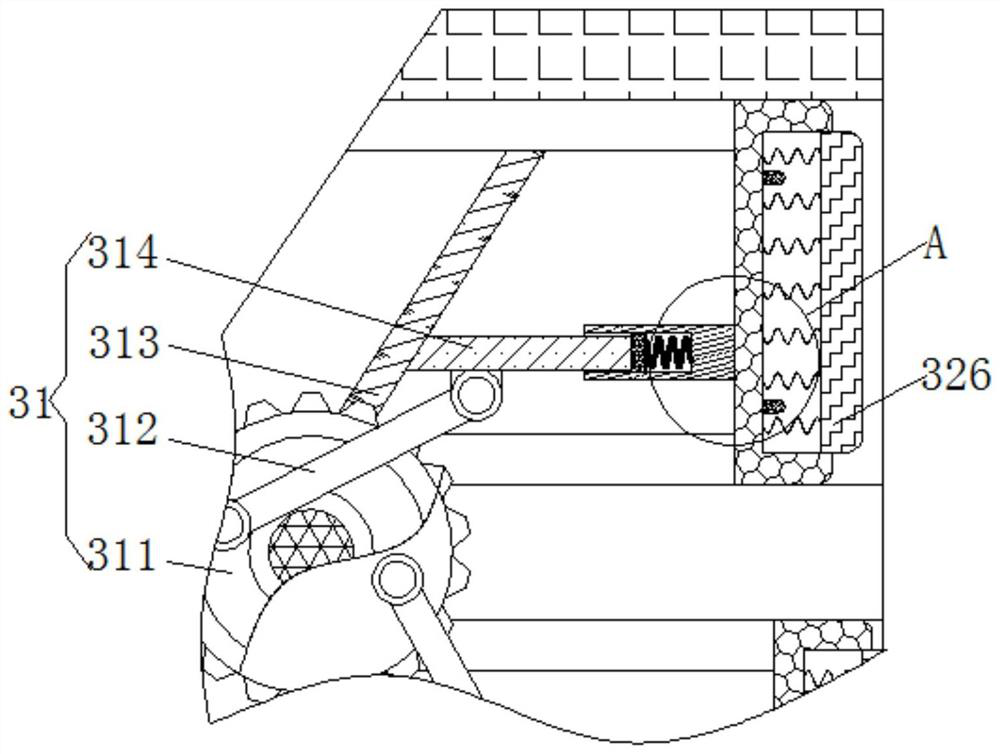

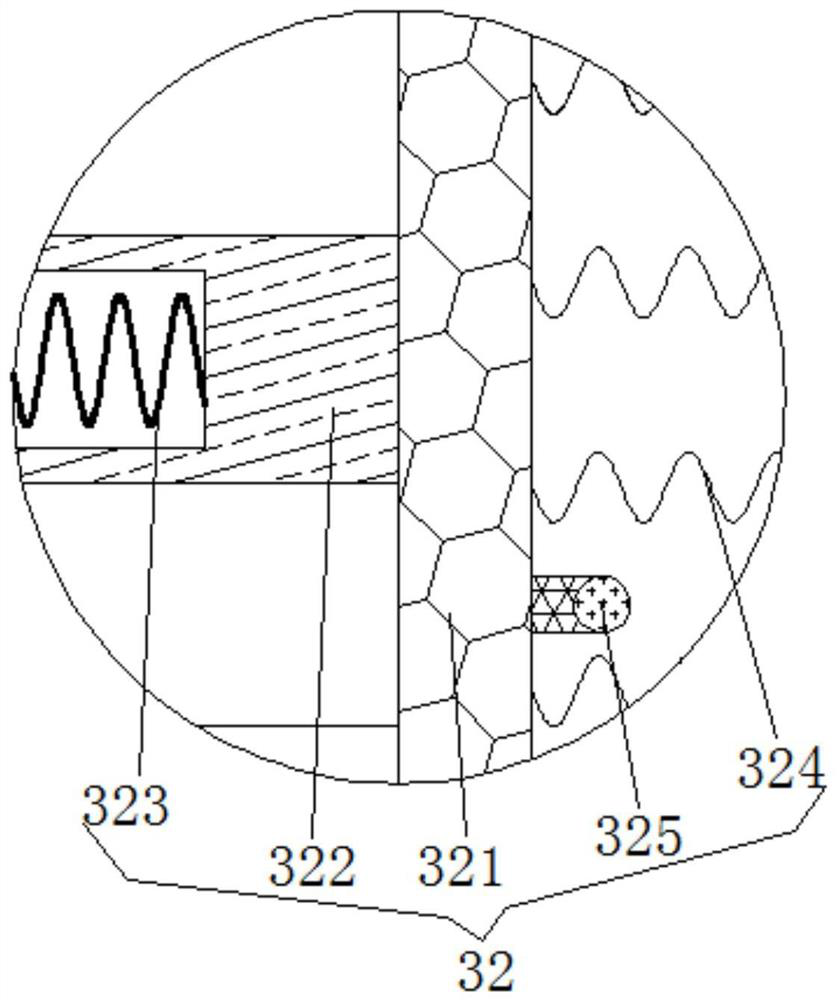

[0026] see Figure 1-3 , an auxiliary cleaning device for cutting aluminum-shaped plates, including a casing 1, a driving wheel 2 is rotatably connected to the inside of the casing 1, and a fixing mechanism 3 is movably connected to the outside of the driving wheel 2, and the fixing mechanism 3 includes a driving wheel 2 that can The transmission assembly 31 of the transmission, the fixed assembly 32 that can be moved by the transmission assembly 31, the transmission assembly 31 includes a rotating wheel 311, a connecting rod 312, a sliding frame 313, and a push rod 314, and the rotating wheel 311 is meshed and connected to the outside of the driving wheel 2. The rod 312 is movably connected to the outside of the rotating wheel 311, the sliding frame 313 is fixedly connected to the inside of the housing 1, the push rod 314 is slidably connected to the inner side of the sliding frame 313, and the end of the connecting rod 312 away from the rotating wheel 311 is movably connected...

Embodiment 2

[0028] see Figure 4-5 The inside of the housing 1 is movably connected with a dust removal mechanism 4. The dust removal mechanism 4 includes a movable assembly 41 that can be rotated by the drive wheel 2, an air collection bag 42, and an air outlet assembly 43 that discharges air from the air collection bag 42. The movable assembly 41 includes a rotating frame. 411, telescopic rod 412, buffer spring one 413, rotating frame two 414, movable wheel 415, rotating frame one 411 is rotatably connected to the outside of driving wheel 2, telescopic rod 412 is fixedly connected in the inside of rotating frame one 411, buffer spring one 413 Fixedly connected to the outside of the telescopic rod 412, the rotating frame one 411 is fixedly connected to the outside of the telescopic rod 412, the movable wheel 415 is rotatably connected to the outside of the rotating frame two 414, the movable wheel 415 is movably connected to the inner wall of the air collection bag 42, and the air outlet ...

Embodiment 3

[0030] see Figure 1-5, an auxiliary cleaning device for cutting aluminum-shaped plates, including a casing 1, a driving wheel 2 is rotatably connected to the inside of the casing 1, and a fixing mechanism 3 is movably connected to the outside of the driving wheel 2, and the fixing mechanism 3 includes a driving wheel 2 that can The transmission assembly 31 of the transmission, the fixed assembly 32 that can be moved by the transmission assembly 31, the transmission assembly 31 includes a rotating wheel 311, a connecting rod 312, a sliding frame 313, and a push rod 314, and the rotating wheel 311 is meshed and connected to the outside of the driving wheel 2. The rod 312 is movably connected to the outside of the rotating wheel 311, the sliding frame 313 is fixedly connected to the inside of the housing 1, the push rod 314 is slidably connected to the inner side of the sliding frame 313, and the end of the connecting rod 312 away from the rotating wheel 311 is movably connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com