Novel waste conveying belt protection device and waste conveying device

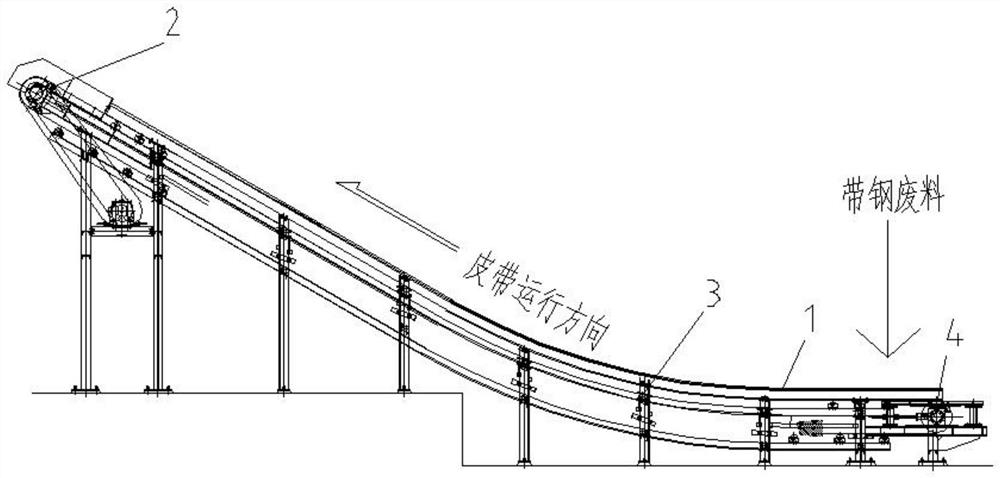

A transport belt and protection device technology is applied in the field of new waste transport belt protection device and waste transport device, which can solve problems such as easy jamming of equipment and easy damage to belts, achieve safe operation, simplify manufacturing and replacement, and save equipment maintenance cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

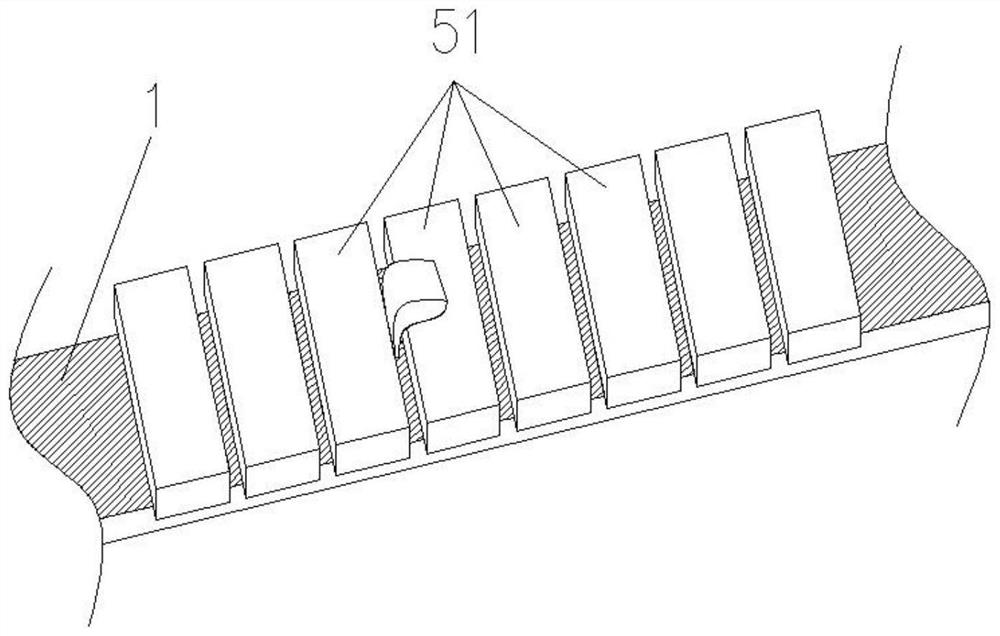

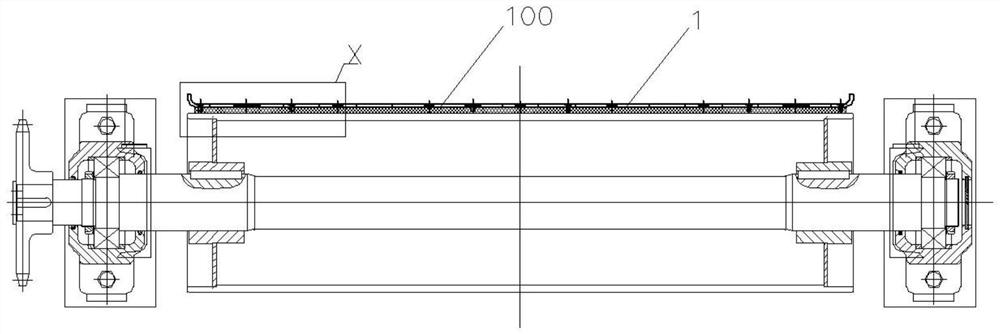

[0048] In a possible embodiment, such as Figure 4 with Figure 5 As shown, the first adjacent surface formed by two adjacent pallet units 100 includes a first plane 201 and a second plane 202, and the first plane 201 and the second plane 202 are alternately arranged to form the adjacent surface 200 , the first plane 201 and the second plane 202 are perpendicular, and one of the first plane 201 or the second plane 202 is consistent with the belt movement direction. In this embodiment, this kind of pallet unit is easy to process, and a certain structural strength can be achieved by setting the lengths of the first plane 201 and the second plane 202. In consideration of reducing the total length of the gap, in the figure The length of the second plane consistent with the belt movement direction should be set shorter, for example, the length ratio of the first plane to the second plane is preferably 4:1-10:1.

Embodiment 2

[0050] In another feasible embodiment, such as Image 6 As shown, the first adjacent surface formed by two adjacent pallet units 100 includes a first plane 201 and a second plane 202, and the first plane 201 and the second plane 202 are alternately arranged to form the adjacent surface 200 , the first plane 201 and the second plane 202 may be perpendicular, or may form a certain angle, and at the same time, the first plane or the second plane and the belt movement direction also have an angle α. The pallet unit in this embodiment is also easy to process, and according to different usage requirements, the angle value of α can be adjusted correspondingly, which is more flexible.

Embodiment 3

[0052] In yet another feasible embodiment, such as Figure 7 As shown, the difference from the second embodiment is that in this embodiment, the angle α is changed from the acute angle in the second embodiment to an obtuse angle, so the shape of the contact surface is also changed from a triangle to a trapezoidal structure. This slightly increases the difficulty, but further reduces the chances of strip scrap corners getting inserted into the gaps.

[0053] It can be known from the first to third embodiments above that the included angle between the first plane 201 and the second plane 202 can be selected within the range of 0° to 180°, which is more flexible.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com