Intelligent anti-rollover crane

A crane and anti-rollover technology, which is applied in hoisting devices, load hanging components, safety devices, etc., can solve the problems of low stability and rollover of cranes, improve connection stability, improve support stability, reduce rollover effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

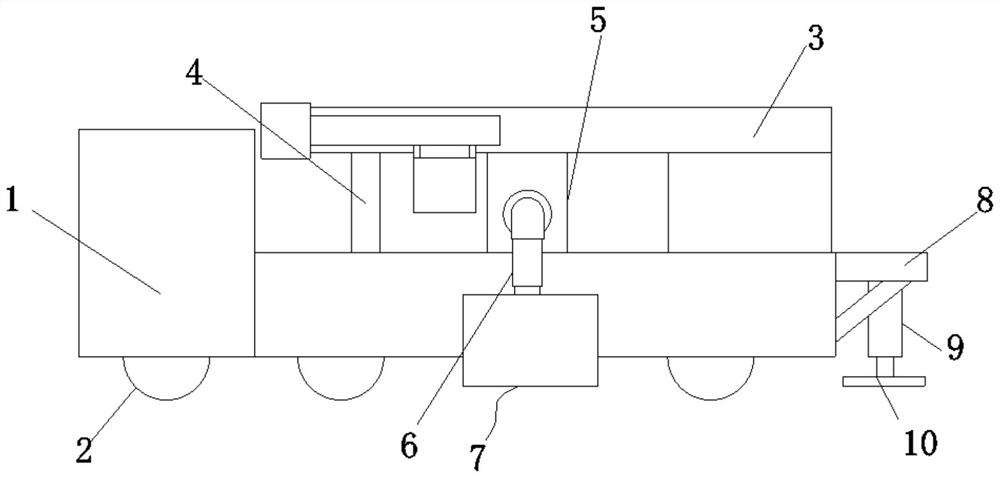

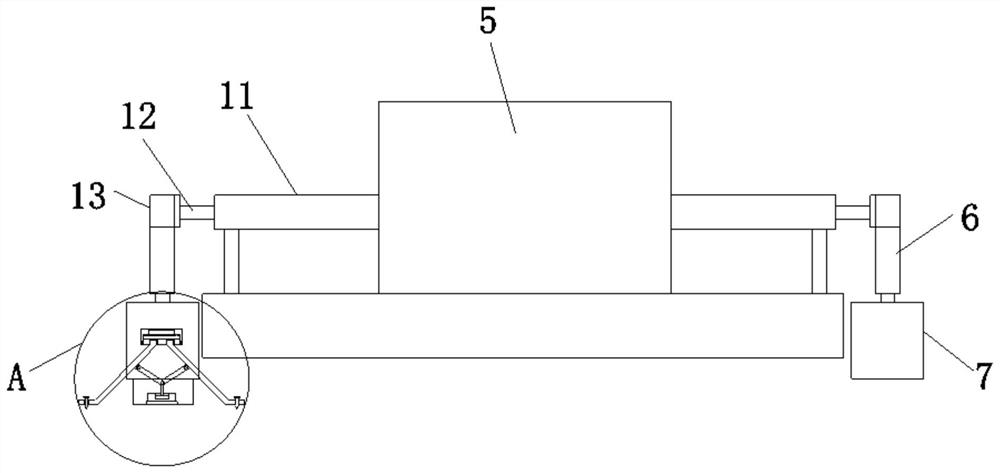

[0033] Embodiment one, by Figure 1 to Figure 8Given, the present invention comprises car body 1 and crane body 3, and the bottom end of car body 1 is provided with moving wheel 2, and crane body 3 is positioned at the top of car body 1, and the top of car body 1 is provided with the support that is connected with crane body 3 The column 4, through the design of the support column 4, is convenient to realize the support to the crane body 3, the top middle position of the car body 1 is provided with the support box 5 connected with the crane body 3, and through the design of the support box 5, it is convenient to realize the support of the crane body. 3, the top of the protective cover 15 is provided with a pressure block connected to the top of the support box 5, through the design of the pressure block, the support performance of the support box 5 is improved, and the two sides of the support box 5 are symmetrically provided with connection seats 13. The bottom end of the con...

Embodiment 2

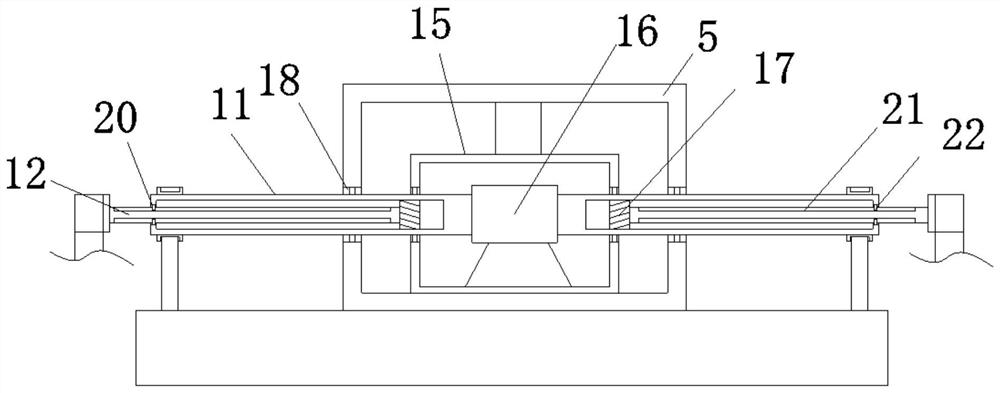

[0036] Embodiment two, on the basis of embodiment one, by figure 1 , figure 2 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 Given, the support element 7 includes a support mechanism one, a support mechanism two and a support member, and the support mechanism one includes a support cover one 23, a slot 25, a tooth plate 26, a convex plate 32, a dividing plate 41, a slide rail 42 and a driver, and supports Cover one 23 is installed in the output shaft bottom end of electric telescopic link one 6, and the inside of support cover one 23 is provided with dividing plate 41, and both sides of support cover one 23 are symmetrically provided with groove 25, and the inside of groove 25 is all interspersed with Tooth plate 26, both sides of tooth plate 26 are provided with convex plate 32 symmetrically, and the top of dividing plate 41 is all provided with the slide rail 42 that is slidingly connected with convex plate 32, is connected by driver between two tooth pl...

Embodiment 3

[0038] Embodiment three, on the basis of embodiment two, by Figure 5 , Image 6 with Figure 7 Given, the support mechanism two includes an opening, a support cover two 24, a support rod 27, a support block 28, a groove 29, a stabilizing bar 51, a stabilizing groove 52, an expander and a height adjustment member, and the support cover two 24 is installed on a support cover one 23, the worm screw 44 and the support cover two 24 are connected by a height adjustment member, the bottom ends of both sides of the support cover two 24 are provided with openings, and the inside of the opening is interspersed with support rods 27, and the bottom of the support rods 27 End one side is all provided with support block 28, and the top side of support rod 27 is all provided with the groove 29 that is connected with support member, and the bottom both sides of dividing plate 41 is all provided with stabilizing bar 51, and the top of support cover 24 Both sides are symmetrically provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com