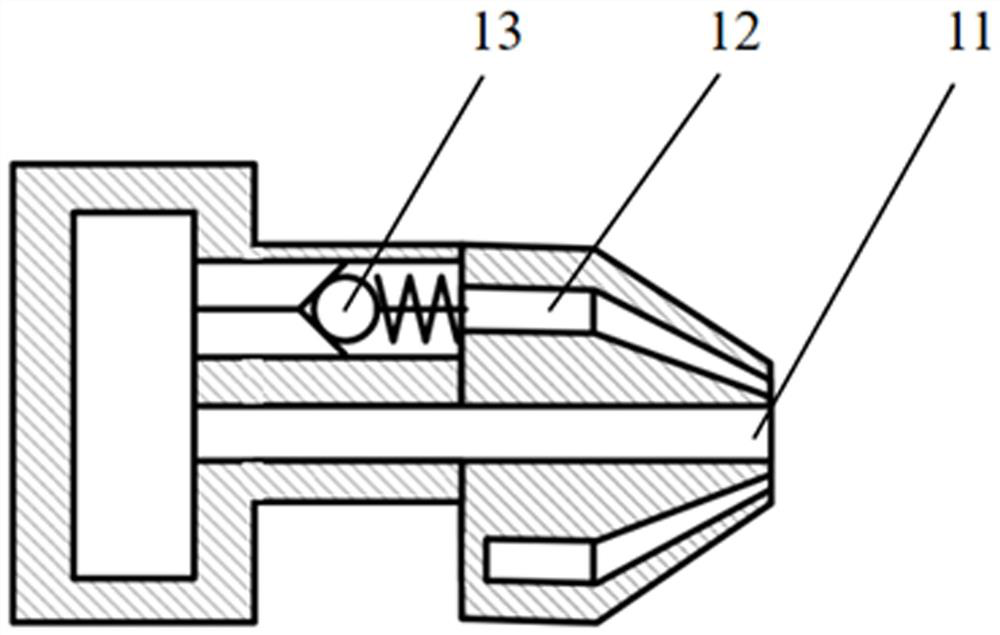

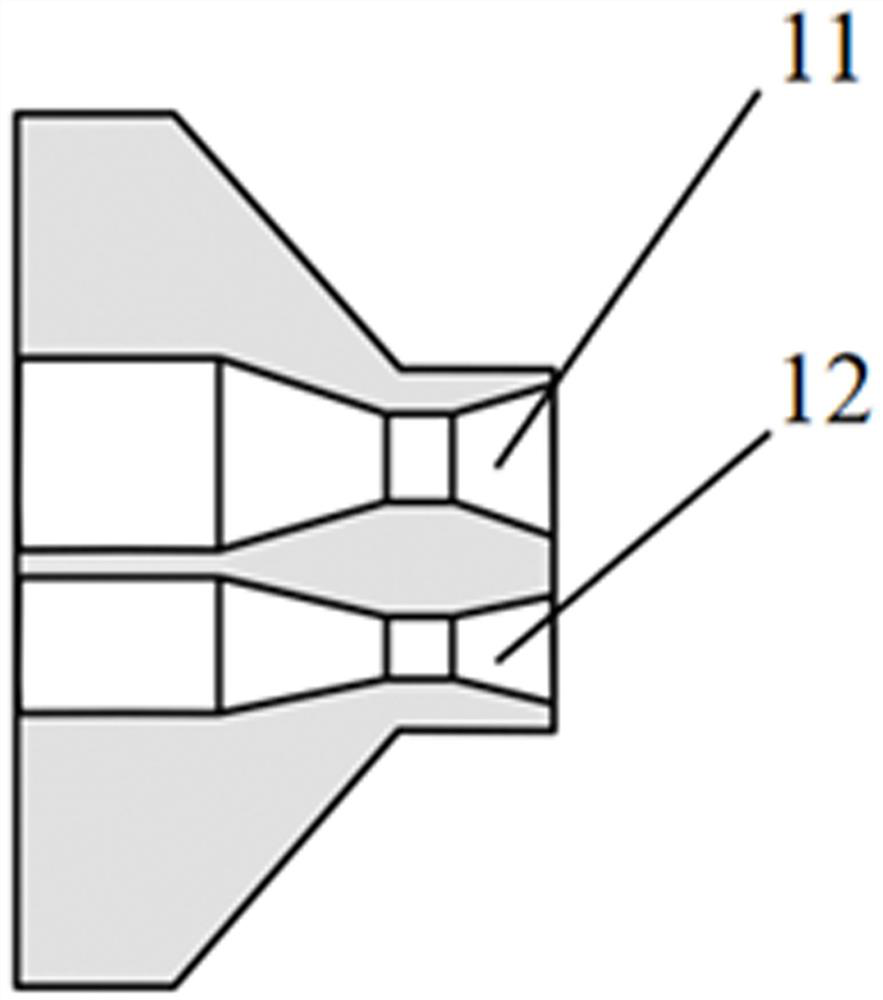

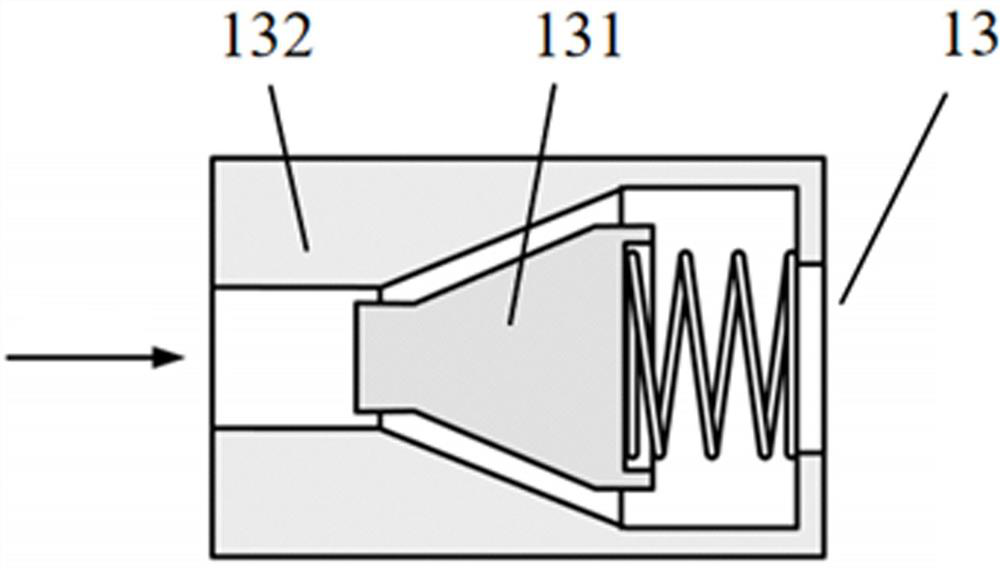

Ejector with multi-mode nozzle, fuel cell system and control method

A fuel cell system, multi-mode technology, applied in fuel cells, jet pumps, circuits, etc., can solve problems such as poor stability, high cost, complex structure, etc., to reduce pressure performance requirements, improve efficiency, and increase the injection cross-sectional area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present disclosure will be described in more detail below with reference to the accompanying drawings. Although embodiments of the present disclosure are shown in the drawings, it should be understood that the present disclosure may be embodied in various forms and should not be limited to the embodiments set forth herein. Rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the scope of the disclosure to those skilled in the art.

[0028] As used herein, the term "comprise" and its variants mean open inclusion, ie "including but not limited to". The term "or" means "and / or" unless otherwise stated. The term "based on" means "based at least in part on". The terms "connected" and "communicated" mean connected or communicated directly or indirectly through other components. The terms "first", "second" and so on may refer to different or the same objects, but do not directly indicate a dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com