Raw material weighing device for neodymium iron boron rapid hardening sheet production

A technology of sheet production and weighing devices, which is applied in the direction of measuring devices, weighing equipment and applications of materials with special properties/forms, and can solve problems such as manual calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

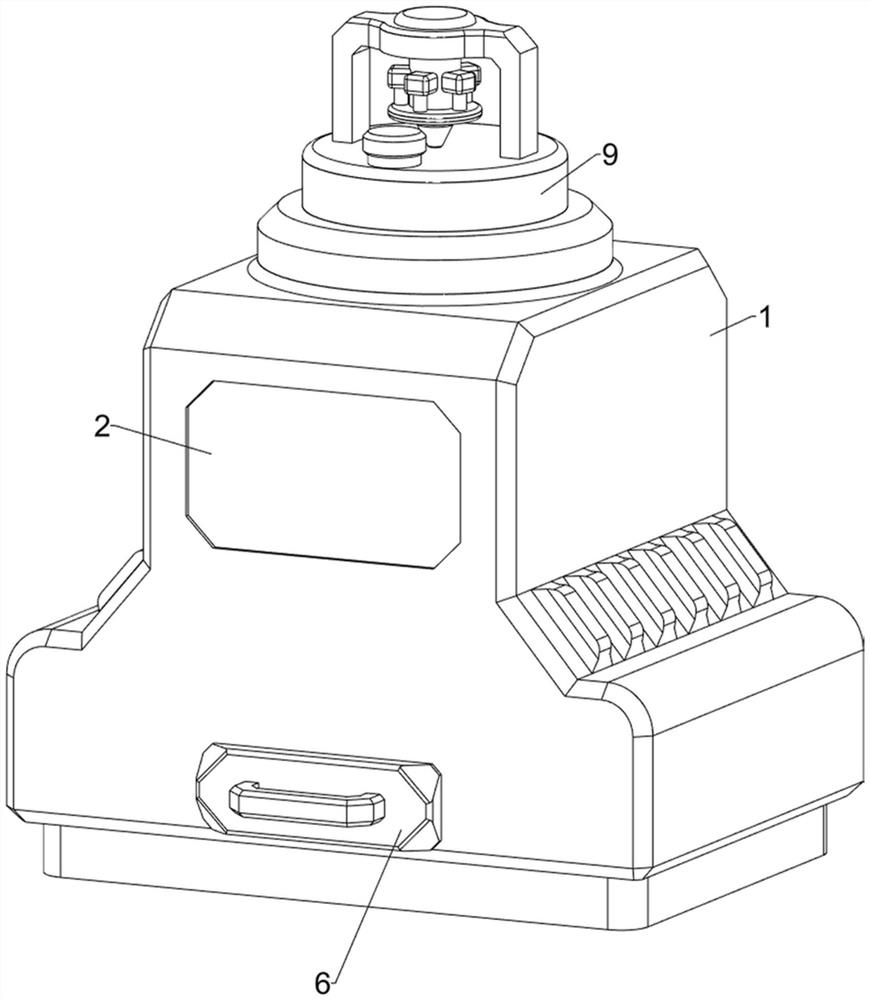

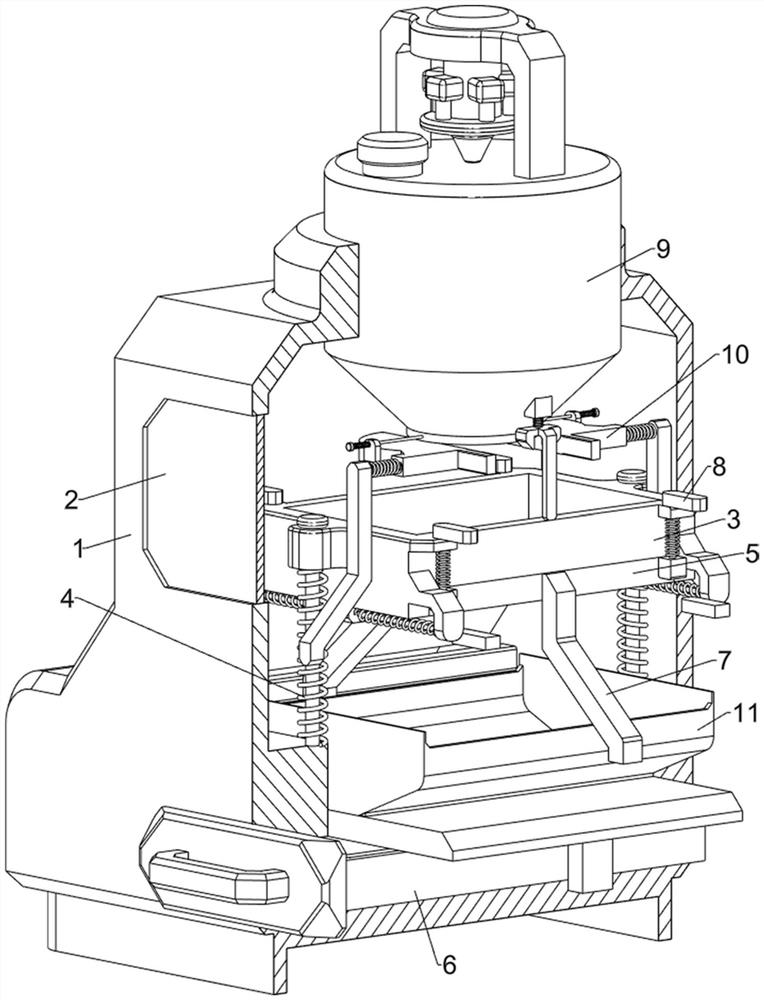

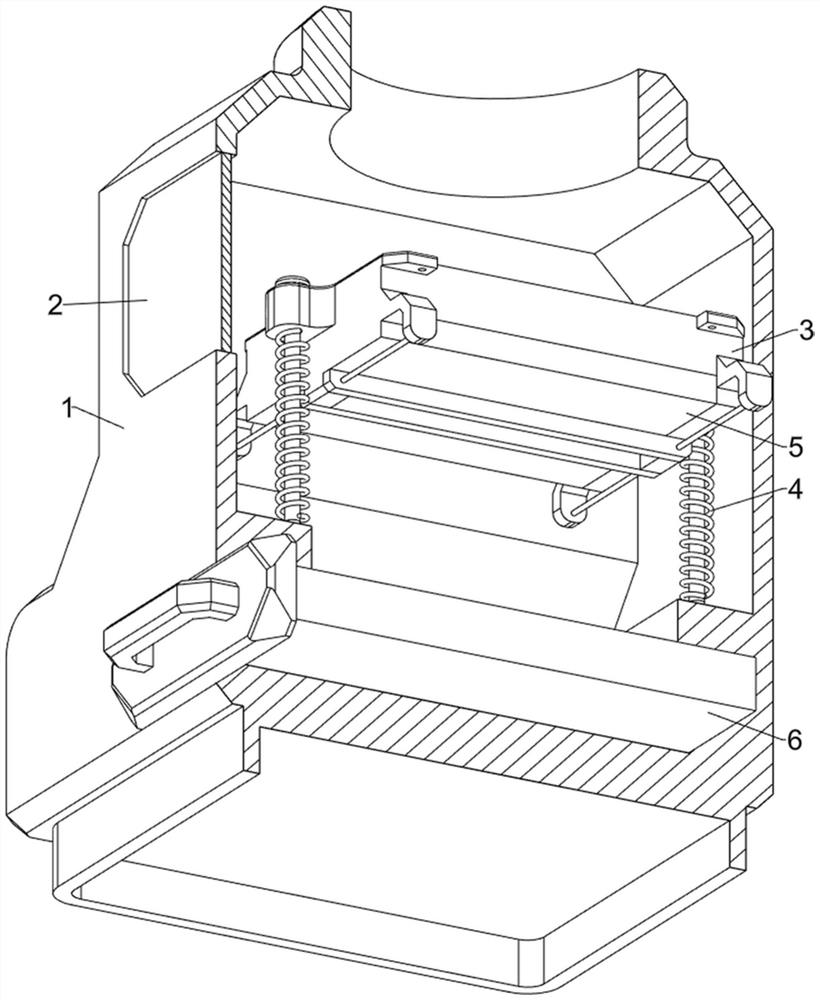

[0037] A raw material weighing device for the production of NdFeB quick-setting flakes, reference Figure 1- Figure 7, including shell 1, observation glass 2, support frame 3, first spring 4, first baffle 5, collection box 6, open component 7 and stuck component 8, the front side of the upper part of the shell 1 is provided with observation glass 2, the inner middle of the shell 1 is provided with a support frame 3, the upper middle of the upper middle of the front and rear sides of the support frame 3 and the upper middle of the shell 1 are equipped with a first spring 4, the lower part of the support frame 3 is symmetrical sliding type with the first baffle 5, when people pour raw material into the support frame 3, the first baffle 5 can block the raw material, Housing 1 in the lower middle sliding type is provided with a collection box 6, when the raw material in the support frame 3 reaches a certain amount, the first baffle 5 will move outward to open, so that the raw material...

Embodiment 2

[0042] On the basis of Example 1, reference Figure 1 、 Figure 2 、 Figure 8 and Figure 9 , also includes a grinding assembly 9, grinding components comprising a storage tank 91, with a hole leak disc 92, a support rod 93, a motor 94, a grinding disc 95 and a dust cover 96, the upper middle of the shell 1 is provided with a storage tank 91, the inner lower part of the storage tank 91 is equipped with a hole leakage plate 92 and connected, the storage tank 91 is welded with a support rod 93, the upper middle of the support rod 93 is bolted to the motor 94, the output shaft of the motor 94 is provided with a grinding disc 95, and the grinding disc 95 is connected to the storage tank 91 rotary connection. The bottom of the grinding disc 95 is in contact with the bottom of the leakage disc 92 with a hole, starting the motor 94, which can drive the grinding disc 95 to rotate, thereby grinding the raw material, the storage tank 91 is placed on the front side of the top cover 96.

[0043]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com