Laser drilling device

A laser drilling and laser beam technology, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve problems such as increased cost and complicated installation, and achieve easy processing, ensure workpiece processing area, and large laser beam angle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

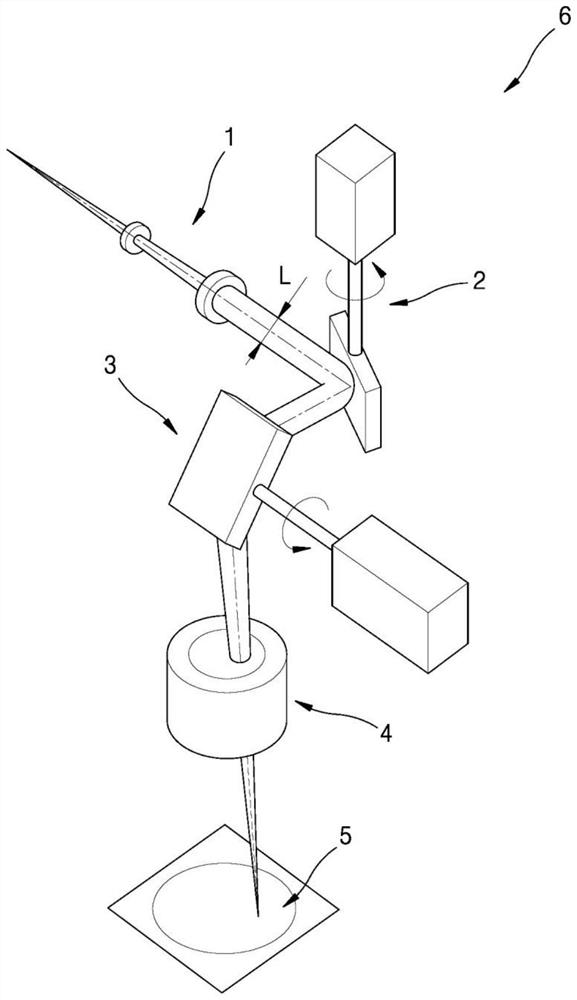

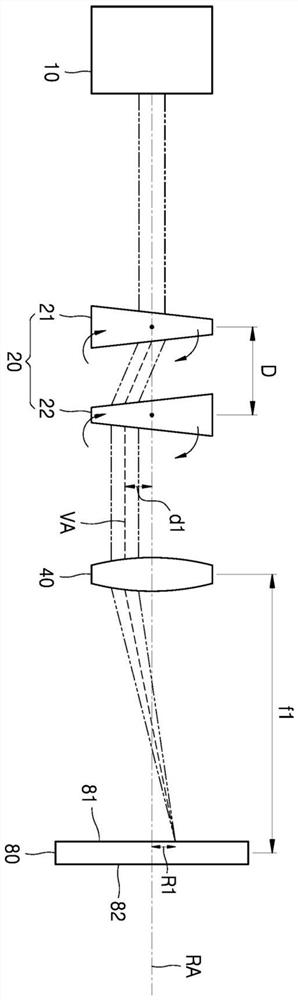

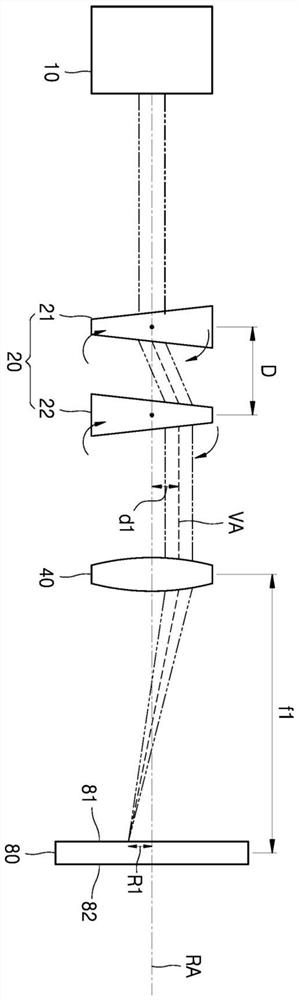

[0033] figure 2 is a conceptual diagram of a laser drilling device according to an embodiment of the present invention, image 3 is showing figure 2 A diagram of the state in which the optical axis moving part is rotated 180 degrees, Figure 4 is shown from figure 2 Punch to image 3 The top view of the state, Figure 5 yes figure 2 A side view of the state in which the optical axis moving part is rotated and punched. Figure 6 is showing figure 2 The diagram of the state where the focal length of the laser beam is changed to f2 in Figure 7 yes Figure 6 A side view of the state in which the optical axis moving part is rotated and punched, Figure 8 is showing Figure 6 In the state where the focal length of the laser beam is changed to f3, Figure 9 is showing Figure 8 A side view of the state in which the optical axis movi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com