Multi-stage rotational flow particle suspended matter discharging device and process thereof

A particle suspension and swirling technology, which is applied in the feeding/discharging device of the settling tank, separating sediments by centrifugal force, filtering and separating, etc., can solve the problem of long-term high particle content in sewage discharge, high impact load of water treatment facilities, and drainage Pipeline and water pump wear and other problems, to achieve the effect of intelligent environmental protection and efficient drainage, improve water treatment efficiency, and reduce pipeline wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

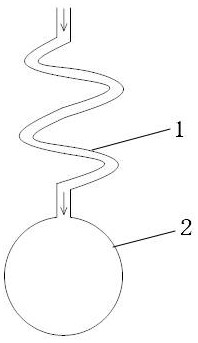

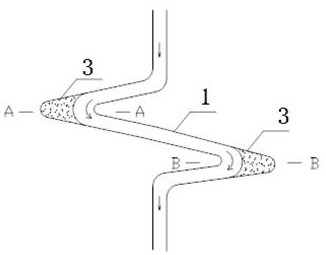

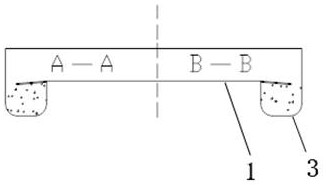

[0024] Such as Figure 1 to Figure 4 As shown, this specific embodiment provides a multi-stage swirl discharge device for suspended particles, including a plurality of continuously arranged S-shaped swirl settling channels 1 and filter tanks 2, and the downstream S-shaped swirl settling channel 1 is connected to Through the filter tank 2; the S-shaped swirl settlement channel 1 has two deflection points, which are respectively the upstream deflection point and the downstream deflection point. The connecting part of the slag collection tank 3 is provided with a dense porous isolation plate 4, and an automatic slag discharge device is installed in the swirling flow slag collection tank 3. Specifically, the automatic slag discharge device includes a sensor 5, a slag discharge pipe 6 and a power device 7, and the sensor 5 is installed on the swirl slag collection tank 3, the slag discharge pipe 6 is connected to the swirl flow slag collection tank 3, the slag discharge pipe 6 is c...

specific Embodiment approach 2

[0025] This specific embodiment provides a multi-stage cyclone row particle suspension process, including the multi-stage cyclone row particle suspension device in Embodiment 1, and also includes the following steps:

[0026] A1: The suspended particles in the water body are naturally precipitated in the river channel, and the large suspended particles can be precipitated; but other suspended particles enter the multi-stage cyclone discharge suspended solids device with the water body, and flow through the S-shaped cyclone sedimentation Qu1;

[0027] A2: When sewage (i.e. water mixed with suspended solids such as rocks, gravels, and sand) flows through the S-shaped swirl settlement channel 1, it first passes through the upstream deflection point, where the dense porous isolation plate 4 acts as a barrier to make the rocks Partial suspended matter such as silt, sand, etc. gradually deposits to the bottom of the end of the deflection point, and deposits in the swirl slag collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com