Solvent-free three-in-one compound equipment based on double-sided coating of middle layer

A composite equipment, double-sided coating technology, applied in the direction of lamination, lamination device, layered products, etc., can solve the problem of inability to glue and compound the intermediate layer substrate, and achieve the effect of improving process adaptability and avoiding restrictions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

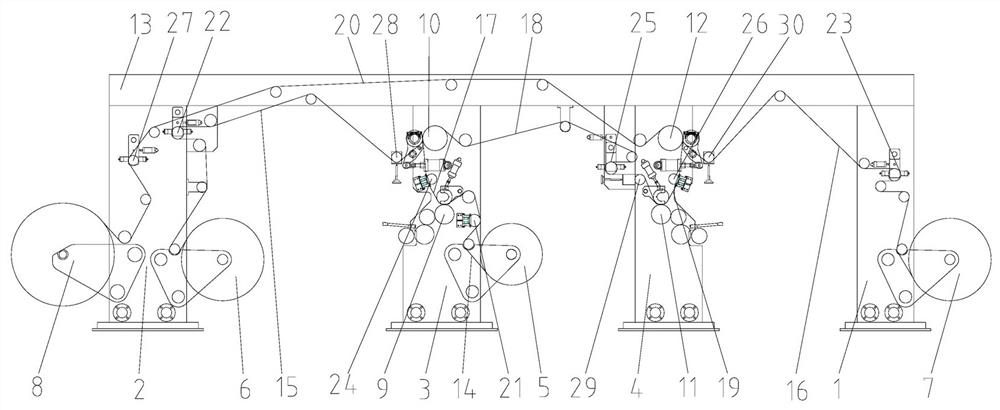

[0024] Such as figure 2 As shown, the four-unit short winding path model, the first unit 1, the second unit 2, the third unit 3 and the fourth unit 4 are arranged side by side under the frame 13 from left to right; the first unit 1 is arranged on the left side There is a third unwinding unit 7; a rewinding unit 8 and a second unwinding unit 6 are arranged on the left and right of the bottom of the second unit 2, and a second compound unit 12 is arranged on the upper left; For the cloth unit 9, the first composite unit 10 is arranged on the upper left, the first unwinding unit 5 is arranged on the lower right; the second coating unit 11 is arranged on the right side of the fourth unit. The material belt path of this model is as follows: the first section of material belt path 14 is between the first unwinding unit 5 and the first coating unit 9 of the third unit 3, and the second section of material belt path 15 is located in the second unit Between the second unwinding unit ...

Embodiment 2

[0026] Such as image 3 As shown, in the four-unit short compound path model, the first unit 2, the second unit 3, the third unit 4 and the fourth unit 1 are arranged side by side under the frame 13 from left to right; the left side of the first unit 2 is arranged with The winding unit 8 is arranged with the second unwinding unit 6 on the right side; the first coating unit 9 is arranged at the lower left of the second unit 3, the first composite unit 10 is arranged at the upper left, and the first unwinding unit is arranged at the lower right 5. The second coating unit 11 is arranged on the lower right of the third unit 4, and the second composite unit 12 is arranged on the upper right; the third unwinding unit 7 is arranged on the right side of the fourth unit 1. The material belt path of this model is as follows: the first section material belt path 14 is located between the first unwinding unit 5 and the first coating unit 9 of the second unit 3, and the second section materi...

Embodiment 3

[0028] Such as Figure 4 As shown, the three-unit external unwinding model, the first unit 1, the second unit 2 and the third unit 33 are arranged side by side under the frame 13 from left to right; the third unwinding unit is arranged on the left side of the first unit 1 7; The winding unit 8 and the second unwinding unit 6 are respectively arranged on the left and right of the lower part of the second unit 2, and the second composite unit 12 is arranged on the upper left; the first coating unit 9 is arranged on the lower left of the third unit 33, and the upper left A first composite unit 10 is arranged, a first unwinding unit 5 is arranged on the lower right, and a second coating unit 11 is arranged on the upper right. The material belt path of this model is as follows: the first section material belt path 14 is located between the first unwinding unit 5 and the first coating unit 9 of the third unit 33, and the second section material belt path 15 is located at the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com