Air compressor joint control method and system and storage medium

An air compressor and joint control technology, applied in pump control, mechanical equipment, machine/engine, etc., can solve the problems of increasing difficulty, many lines of joint control equipment, and large amount of data, so as to reduce the pressure of data processing and improve real-time Response speed, the effect of reducing the number of lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

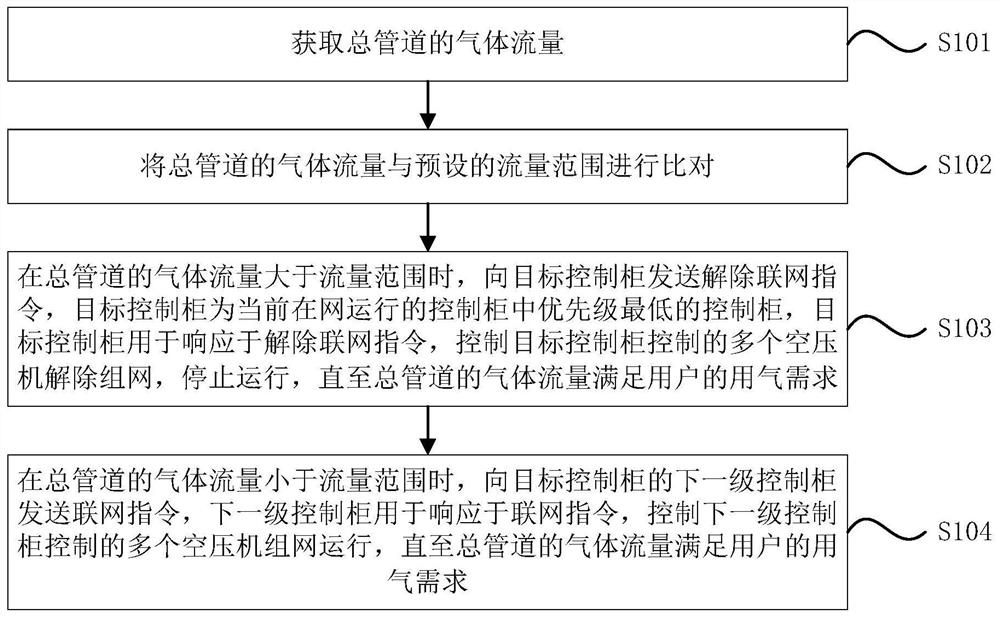

[0049] Figure 1AIt is a flow chart of an air compressor joint control method provided by Embodiment 1 of the present invention. This embodiment is applicable to the situation of multi-stage air compressor joint control. device, which can be implemented by software and / or hardware, and configured in the joint control cabinet provided by the embodiment of the present invention, such as Figure 1A As shown, the method specifically includes the following steps:

[0050] S101. Obtain the gas flow rate of the main pipeline.

[0051] Due to limited factory planning and local space, all air compressors cannot be placed in the same space, and often need to be placed separately in different places to form different air compressor networks, and then the compressed air produced by them Together, they will be aggregated to the manager, and will be uniformly supplied to the terminal.

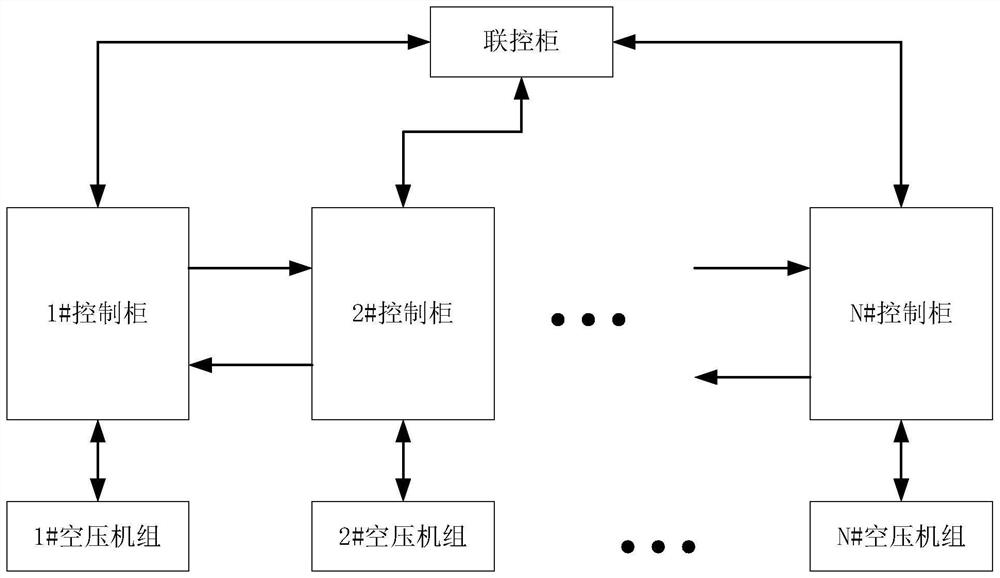

[0052] Figure 1B A schematic structural diagram of an air compressor joint control system provided for...

Embodiment 2

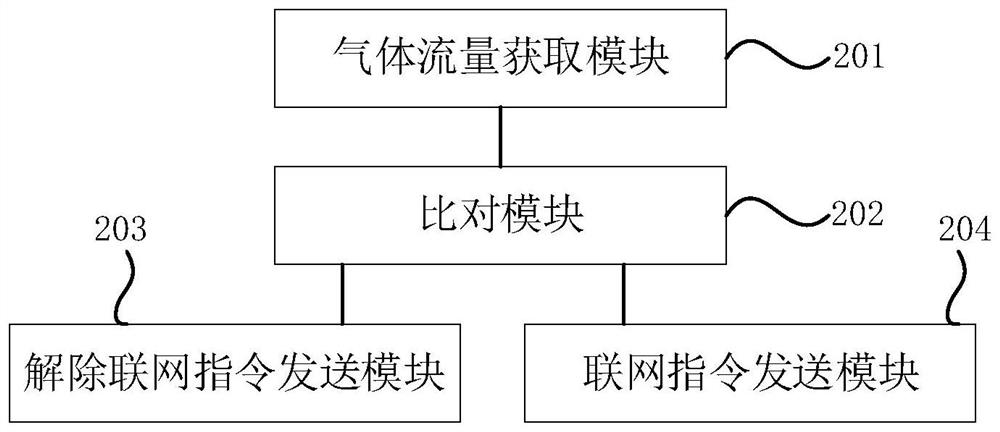

[0093] figure 2 A schematic structural diagram of an air compressor joint control device provided in Embodiment 2 of the present invention, as shown in figure 2 As shown, the device includes:

[0094] A gas flow acquisition module 201, configured to acquire the gas flow of the main pipeline;

[0095] A comparison module 202, which compares the gas flow of the total pipeline with a preset flow range;

[0096] The disconnection command sending module 203 is used to send a disconnection command to the target control cabinet when the gas flow rate of the main pipeline is greater than the flow range, and the target control cabinet has the lowest priority among the control cabinets currently running on the network control cabinet, the target control cabinet is used to respond to the de-network instruction, control the multiple air compressors controlled by the target control cabinet to de-network and stop running until the gas flow of the main pipeline meets the user’s requireme...

Embodiment 3

[0116] Embodiment 3 of the present invention provides an air compressor joint control system, the air compressor joint control system includes:

[0117] Multiple air compressors;

[0118] Multiple control cabinets, each of which controls multiple air compressors;

[0119]A joint control cabinet, the joint control cabinet is connected to the plurality of control cabinets.

[0120] The structure of the air compressor joint control system can be described in the foregoing embodiments and Figure 1B , the embodiment of the present invention will not be repeated here.

[0121] image 3 It is a schematic structural diagram of the joint control cabinet in the embodiment of the present invention, as image 3 As shown, the joint control cabinet includes:

[0122] Processor 301, memory 302, communication module 303, input device 304 and output device 305; the number of processors 301 can be one or more, image 3 Take a processor 301 as an example; the processor 301, the memory 302...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com