Service life prediction and operation and maintenance system for industrial motor

A life prediction, operation and maintenance system technology, applied in the direction of motor generator testing, measuring devices, network data query, etc., can solve the heavy workload of maintenance personnel, the detection data cannot form real-time continuous dynamic trend results, operation and maintenance detection There are many projects, etc., to improve the level of operation and maintenance management, prolong the life of the machine, and reduce the maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

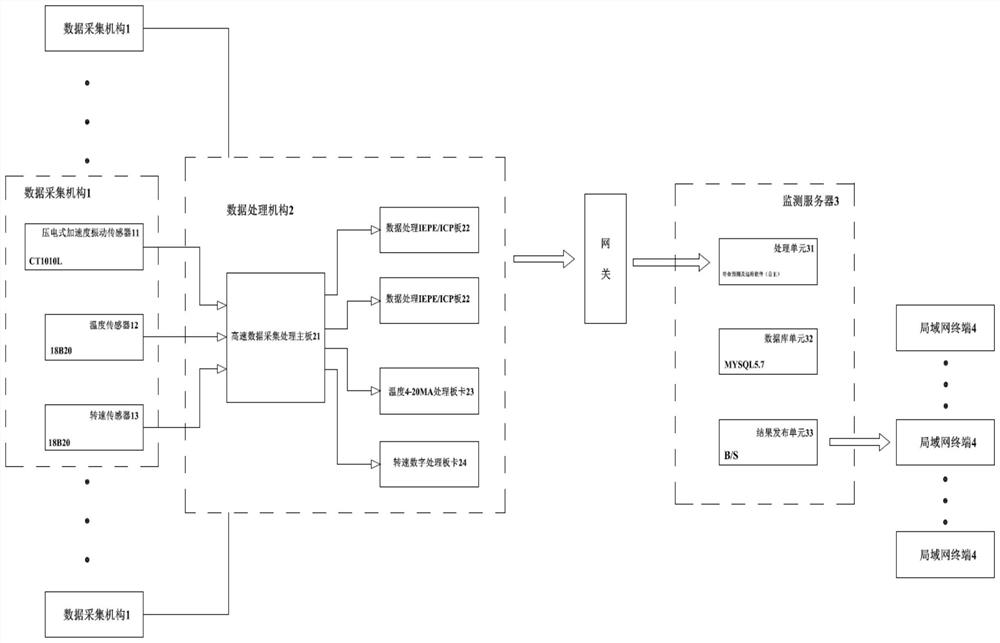

[0031] Implementation mode 1: if figure 1 As shown, the industrial motor life prediction and operation and maintenance system includes a data collection mechanism 1, a data processing mechanism 2, a monitoring server 3, and a local area network terminal 4, wherein the data collection mechanism 1 is set on the target motor for collecting Vibration, temperature, and rotational speed original signals of operation, and upload the original signals to the data processing mechanism 2; the data processing mechanism 2 is used to simulate the vibration, temperature, and rotational speed original signals uploaded by the data acquisition mechanism 1 data conversion, and upload the converted data signal to the monitoring server 3; the monitoring server 3 is arranged on the site where the motor is located or in the machine room, and is used for performing data processing on the data signal uploaded by the data processing mechanism 2, Compare and analyze, display data on site, output spectro...

Embodiment approach 2

[0032] Embodiment 2: The data acquisition mechanism 1 of this industrial motor life prediction and operation and maintenance system includes a piezoelectric acceleration vibration sensor 11 , a temperature sensor 12 , and a rotational speed sensor 13 . The piezoelectric acceleration vibration sensor 11 is installed on the free end and the load end of the target motor in one-to-one correspondence, and the temperature sensor 12 and the rotational speed sensor 13 are respectively installed in one-to-one correspondence on the load end of the target motor. It is used to collect the horizontal vibration of the free end of the motor, the horizontal / vertical / axial vibration of the load end, and the original signal of temperature and speed.

Embodiment approach 3

[0033] Embodiment 3: The data processing mechanism 2 of this industrial motor life prediction and operation and maintenance system includes a high-speed data acquisition and processing main board 21, a data processing IEPE / ICP board 22, a temperature 4-20MA processing board connection 23, and a speed digital processing board twenty four. The output ends of the piezoelectric acceleration vibration sensor 11, temperature sensor 12, and rotational speed sensor 13 are respectively connected with the data processing IEPE / ICP board 22, temperature 4-20MA processing board 23, The rotational speed digital processing board card 24 is connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com