Method for quickly detecting appearance and corresponding device thereof

It is a fast and good-looking technology, which is applied to color TV parts, TV system parts, image analysis, etc. It can solve the problems of affecting the inspection capacity, the inability to guarantee the parallelism of products, and the easy movement of products out of the range of CCD lenses, etc., to achieve improved Check the effect of production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

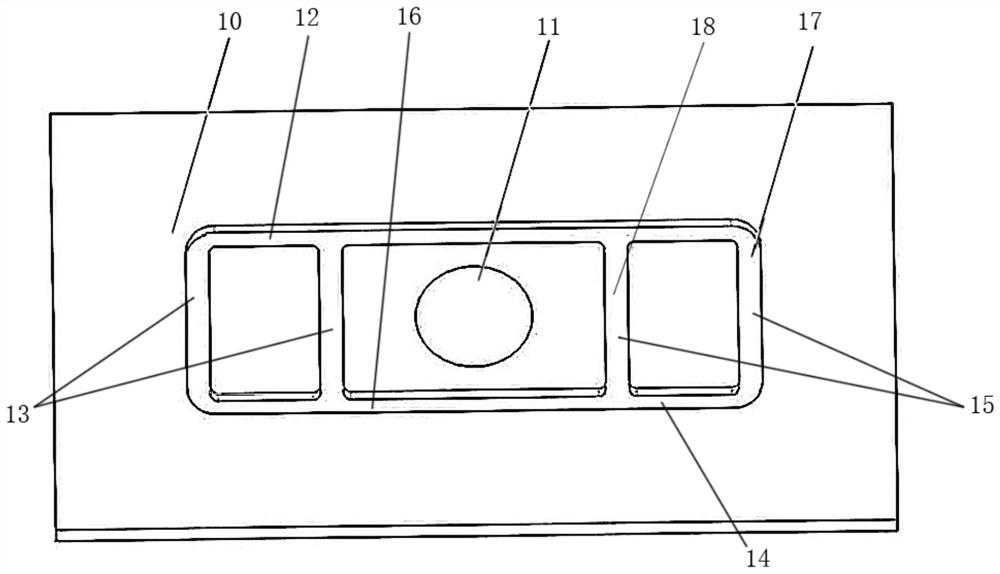

[0031] A method for quick appearance inspection, characterized in that: a 100-fold magnifying glass is attached to the CCD lens, so that the inspector can observe the edge of the product after being magnified by 100, and the CCD lens is arranged facing the base 10 below, and the position of the base 10 is fixed. The 10 central areas of the base are the visual threshold 11 of the CCD lens. On the upper surface 10 of the base, a first side guiding lower groove 12, a second side guiding lower groove 13, a third side guiding lower groove 14, and a fourth side are formed. guide lower groove 15;

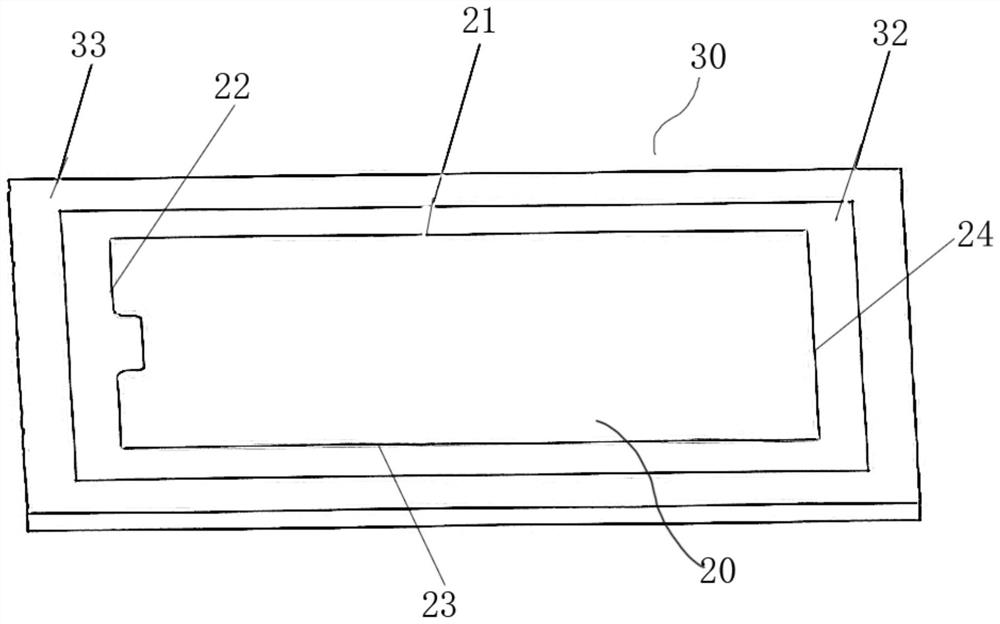

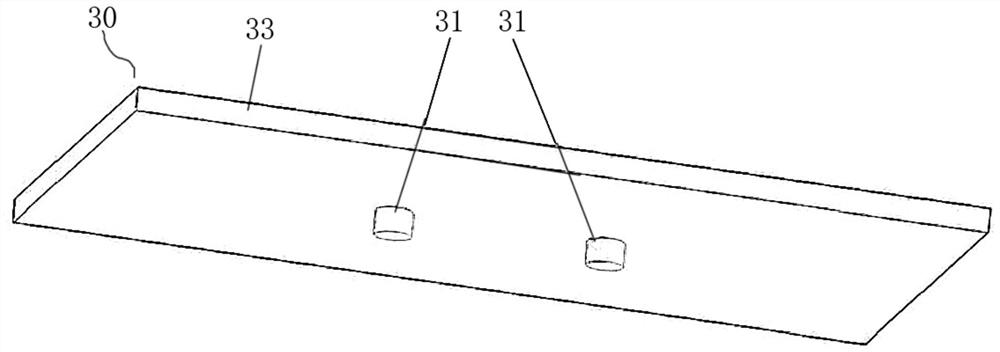

[0032] The product 20 is fixed on the upper surface of the product fixing plate 30, and the lower surface of the product fixing plate 30 is provided with a pair of downward convex moving guide columns 31 arranged at intervals;

[0033] When the moving guide column 31 moves along the first edge to guide the lower groove 12, the visual threshold 11 covers the first edge 21 of the product 20;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com