Unilateral axial magnetic adjusting device of vertical hybrid excitation motor

A hybrid excitation motor, unilateral technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., to achieve the effect of reducing heat, reducing complexity and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

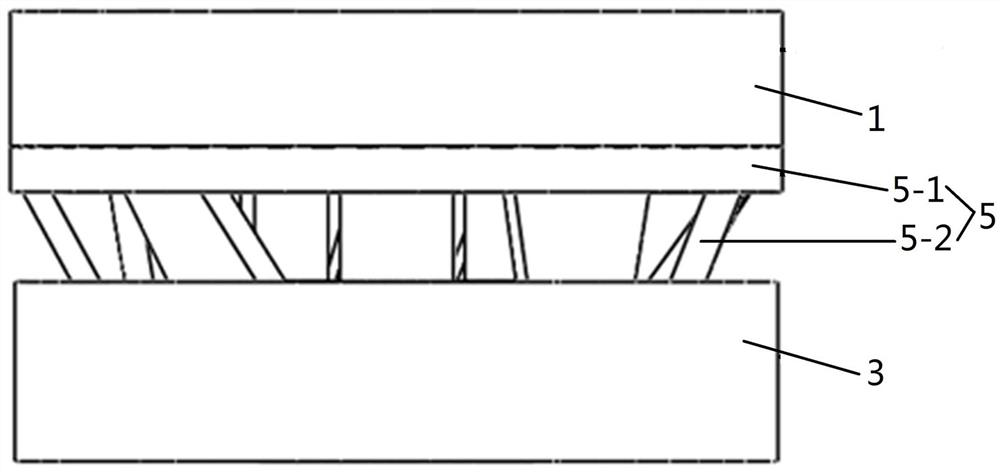

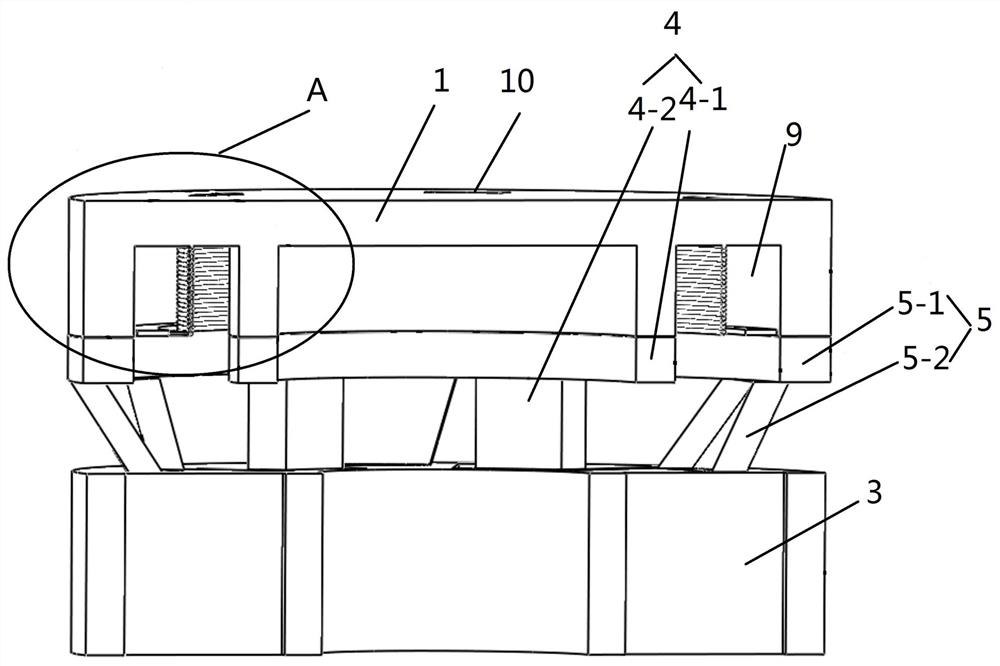

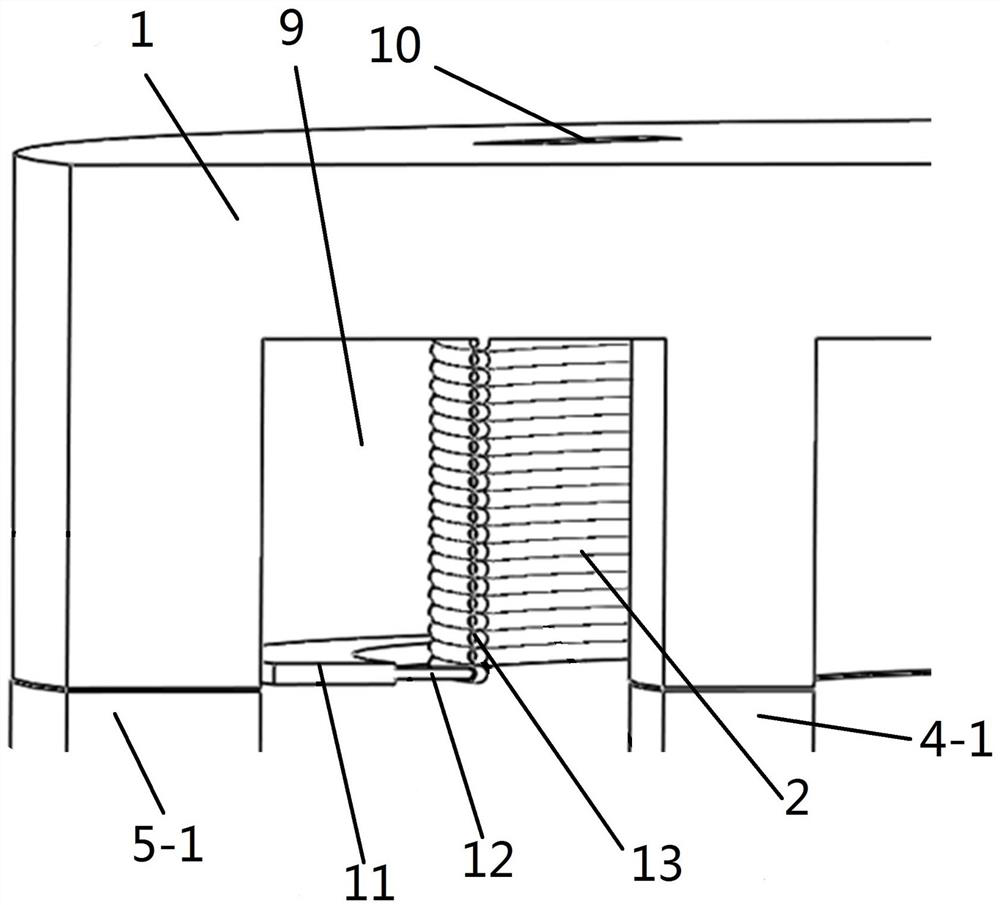

[0040] Embodiment 1: The tangential permanent magnet motor forms the magnetic N area 7 and the magnetic S area 8 distributed at intervals on the rotor 3, and the inner claw pole yoke part 4-2 is placed in the magnetic N area 7, and the outer claw pole yoke part 5 -2 is placed in the magnetic S area 8, the inner claw pole 4 and the outer claw pole 5 rotate with the motor rotor 3; the main magnetic circuit of the permanent magnet 6 in the tangential permanent magnet motor is the permanent magnet 6N pole -> rotor 3 -> Stator->rotor 3->permanent magnet 6S pole; because the inner claw pole 4 and the outer claw pole 5 are made of materials with high magnetic permeability, the permanent magnet 6 will pass through the inner claw pole 4, the outer claw pole 5 and the terminal Cover 1 forms an axial flux leakage, which is not available in the original permanent magnet motor. The axial flux leakage magnetic circuit is permanent magnet N pole -> rotor magnetic N area 7 -> inner claw pole 4...

Embodiment 2

[0059] Embodiment 2: Different from Embodiment 1, the outside of the outer claw pole ring 5-1 is a regular ring-shaped structure, and the inside is a pentagonal structure, which can make the outer claw pole 5 more magnetically conductive, and the The structure can give full play to the upward wind generated by the outer claw pole yoke part 5-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com