Excitation winding dual-mode switching system of hybrid excitation motor and current control mode

A hybrid excitation motor and excitation winding technology, which is applied in the direction of AC motor control, motor, control system, etc., can solve the problems of increased motor core loss, low torque density, large leakage flux, etc., to improve work efficiency and reduce The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

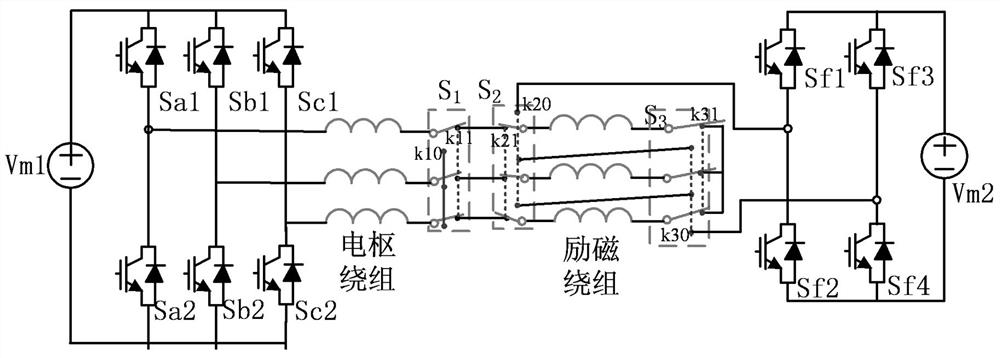

[0025] Example 1: A hybrid excitation motor excitation winding dual mode switching system and current control mode, comprising armature winding, excitation winding, three-leg power converter and two-bridge-arm power converter, armature winding through the three-leg power converter for power supply, excitation winding through the second-bridge-arm power converter for power supply.

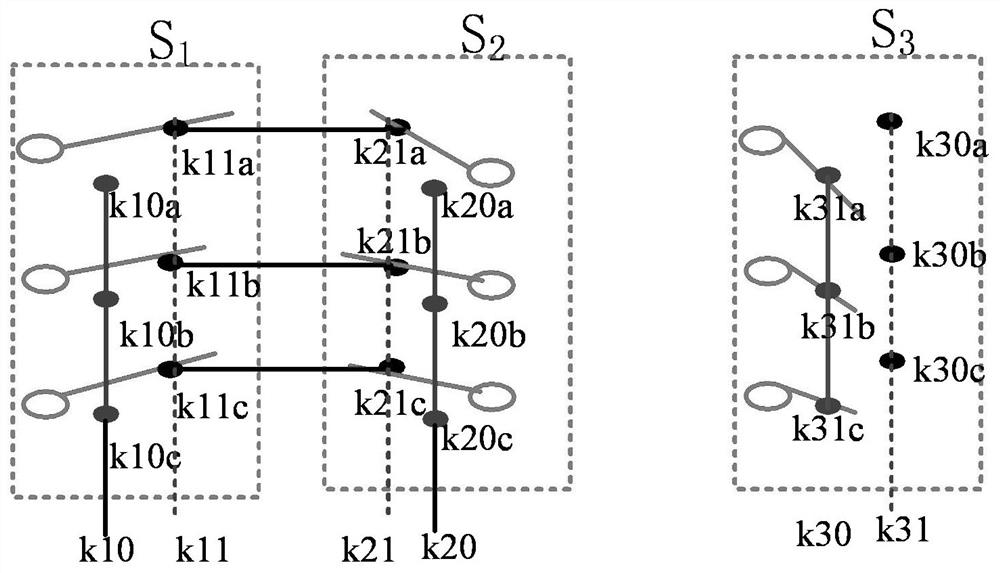

[0026]The three midpoints of the three-arm power converter are connected to the three-phase head end of the armature windings; The two midpoints of the two bridge arms of the two-arm power converter are connected to the constant-breaking contacts of the three-consecutive electrical switch S2 k20_a and the normal-breaking contacts of the three-consecutive electrical switch S3 k30_c respectively; The three-phase constant-break contact k20_a, k20_b, and k20_c of the three-phase electrical switch S2 are k30_b connected to the first midpoint of the second-leg power converter, the normal-break contact k30_a o...

Embodiment 2

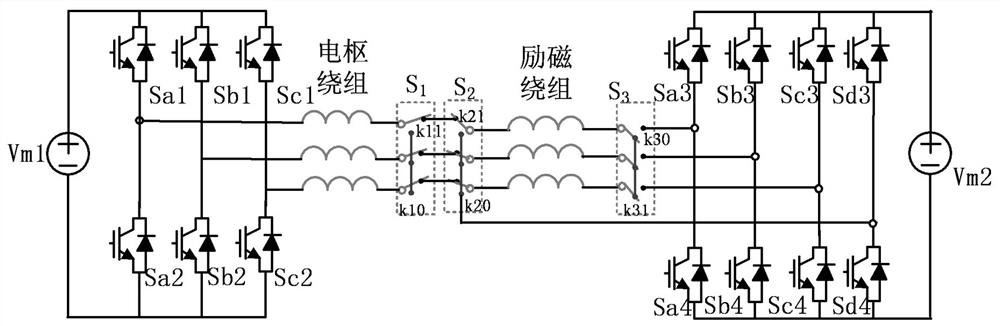

[0030]Example 2: Different from Example 1 is that: the use of a four-leg power converter to replace the two-leg power converter, i.e., the armature windings are powered by a three-arm power converter, and the excitation windings are powered by a four-leg power converter.

[0031] The three midpoints of the three-arm power converter are connected to the three-phase head end of the armature windings; The midpoint of the first three bridge arms of the four-arm power converter is connected to the normal-break contacts k30_a, k30_b and k30_c of the three successive electrical switches S3, respectively, and the fourth midpoint of the four-arm power converter is connected to the constant-breaking contacts of the three-consecutive electrical switch S2 k20_a, k20_b and k20_c; The inlet end of the three-phase electrical switch S1 is connected to the three-phase end of the armature winding, the three-phase constant-break contact k10_a, k10_b, and k10_c phase of the three-phase electrical swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com