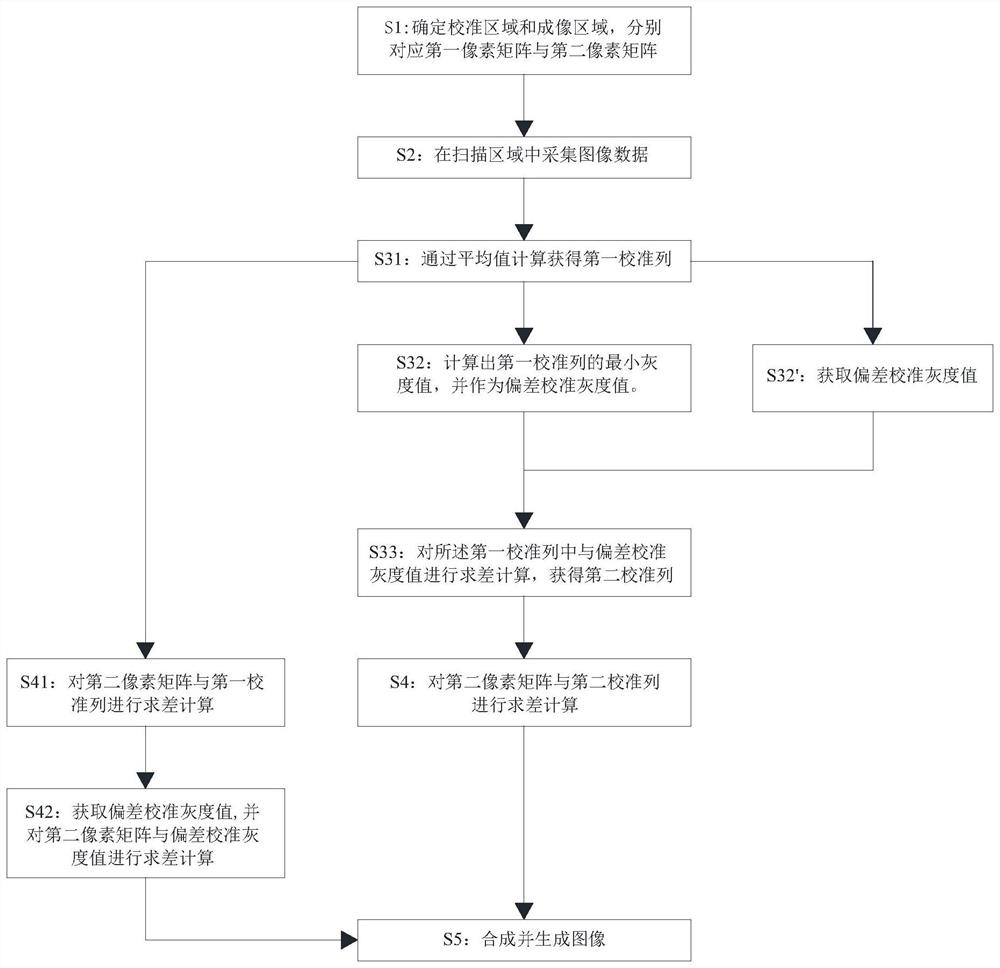

X-ray exposure calibration method, image calibration device and X-ray machine

A calibration method and X-ray technology, applied in the field of image processing, can solve problems such as unusable images, low exposure pulse frequency, and impact on diagnostic results, and achieve the effects of eliminating horizontal stripes, reducing costs, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

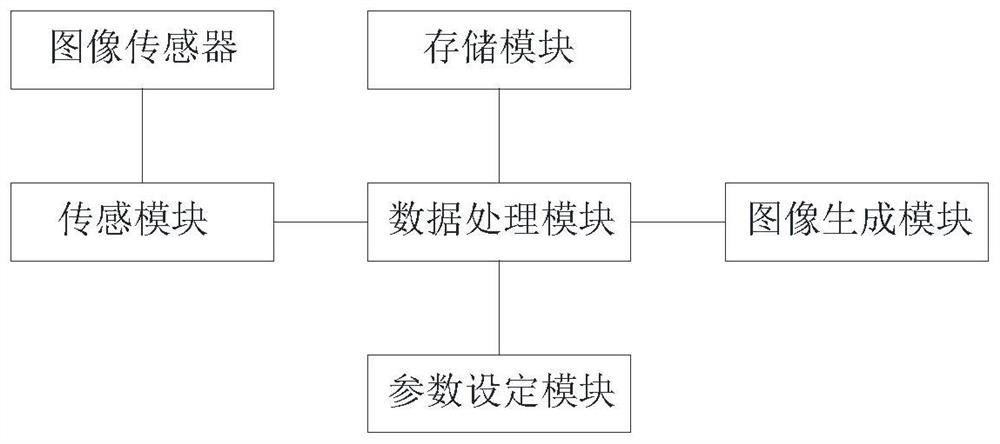

[0033] An image calibration device such as figure 2 As shown, it includes: a storage module, a sensor module, a data processing module, a parameter setting module and an image generation module.

[0034] The data processing module is separately connected with the storage module, the sensing module, the data processing module, the parameter setting module and the image generating module.

[0035] The storage module is used to store the data; the sensing module is connected with an image sensor for collecting image data; the parameter setting module is used for determining the calibration area and the imaging area in the imaging area of the image sensor; the data processing module is used for collecting The X-ray exposure calibration is performed on all image data obtained; the image generation module is used to synthesize an output image according to the image data after exposure calibration.

[0036] The present application also provides an X-ray machine, the X-ray machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com