Plane positioning device based on guiding magnetic scale and positioning method thereof

A positioning device and plane positioning technology, applied in the directions of ground navigation, program-controlled manipulator, manipulator, etc., can solve the problems of inconvenient use and expensive plane positioning equipment, and achieve the effect of low cost, fast automatic search and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

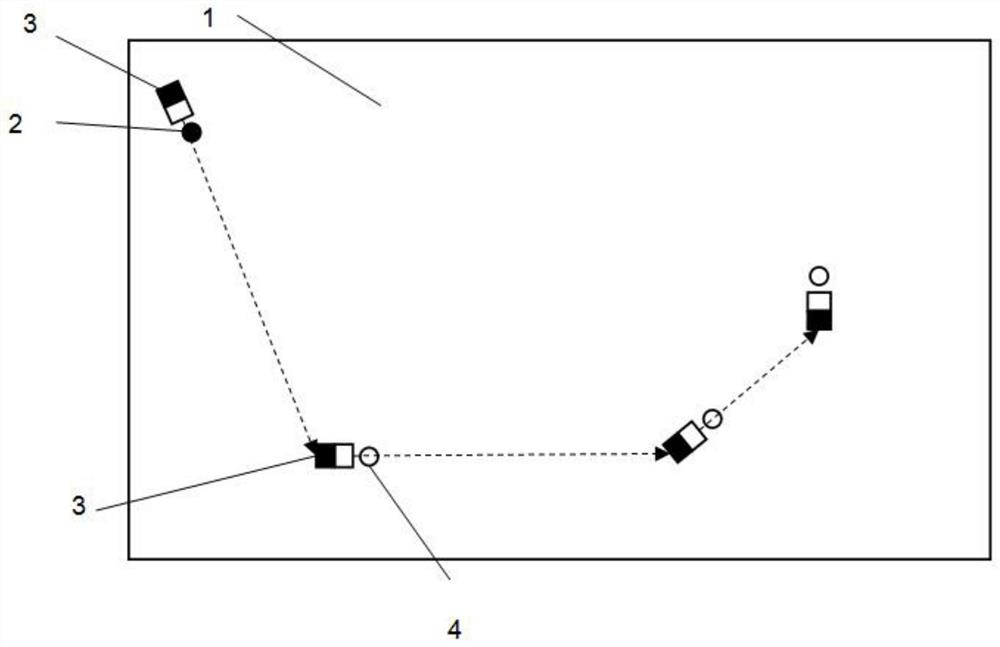

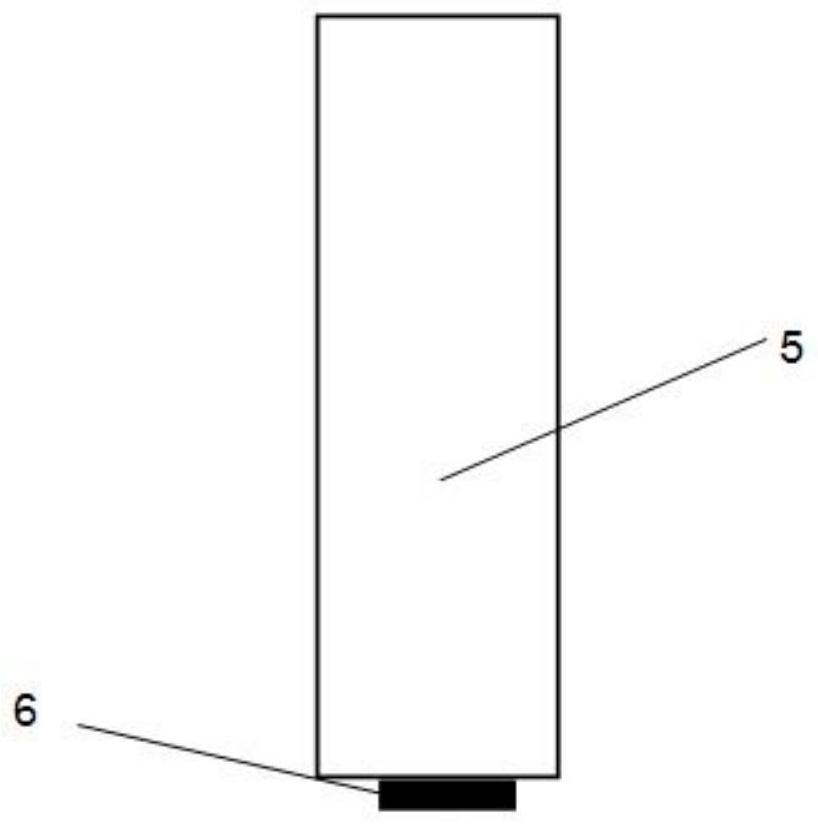

[0037] refer to figure 1 and figure 2 As shown, a plane positioning device based on a guiding magnetic mark includes a non-magnetic sample plate 1 and a mechanical arm 5 . The non-magnetic sample plate 1 is preferably a non-ferromagnetic sample plate. The non-magnetic sample plate 1 is provided with a start position 2 and a sample position 4. The position coordinates of the start position 2 on the non-magnetic sample plate 1 are known.

[0038] Both the starting position 2 and the sample position 4 are provided with a guide magnetic mark 3, the start position 2 and the sample position 4 are located at the magnetic poles of the guide magnetic mark 3, and the magnetic field direction of the previous guide magnetic mark 3 points to the next sample position 4. The magnetic field of the guiding magnetic mark 3 is used to magnetically guide the mechanical arm 5 to form a movement path of the mechanical arm 5 .

[0039] There is an included angle between the magnetic field directi...

Embodiment 2

[0046] refer to figure 1 and figure 2 As shown, a positioning method of the above-mentioned positioning device starts from the initial position 2, and each place is provided with a bar magnet or a coil, and the direction of its magnetic field points to the next sample position. Each sample position 4 is set at a certain fixed magnetic pole of the guiding magnetic mark 3 , that is, after accurately positioning the designated magnetic pole position of the guiding magnetic mark, the mechanical arm can then be aligned with the sample position.

[0047] The sample position is set at the N magnetic pole of each guiding magnetic mark, and the relative orientation from the N magnetic pole is fixed and known.

[0048] In this way, the robotic arm performs positioning and identification of each sample position according to the following steps:

[0049] a. The robotic arm 5 runs to the starting position 2 according to the known coordinates of the starting position 2.

[0050] b. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com