Vulcanization composition for preparing hydrogenated butadiene-acrylonitrile rubber, application of vulcanization composition, hydrogenated butadiene-acrylonitrile rubber and preparation method and application of hydrogenated butadiene-acrylonitrile rubber

A technology of hydrogenated nitrile rubber and liquid nitrile rubber, which is applied in the direction of chemical instruments and methods, other chemical processes, etc., can solve the problem that the oil resistance and aging resistance of hydrogenated nitrile rubber can not meet the requirements of oil resistance and aging resistance And other problems, to achieve high oil resistance, high aging resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0053] However, in order to make the composition of the mixed rubber obtained after mixing more uniform, and to have better mechanical properties and compression set resistance after subsequent vulcanization, according to a preferred embodiment of the present invention, the Mixing includes:

[0054] (1) Component A is mixed for one stage to obtain a masterbatch, which contains a hydrogenated nitrile rubber matrix, an activator, a reinforcing agent, and a plasticizer, and optionally Also contains anti-aging agents;

[0055] (2) Perform two-stage mixing of the masterbatch and component B, and the component B contains an accelerator and a vulcanizing agent.

[0056] According to a preferred embodiment of the present invention, in step (1), the hydrogenated nitrile rubber matrix, activator and optional anti-aging agent in component A are mixed first, and then the reinforcing agent and reinforcing agent are introduced. The plasticizer is mixed for one stage to obtain the masterba...

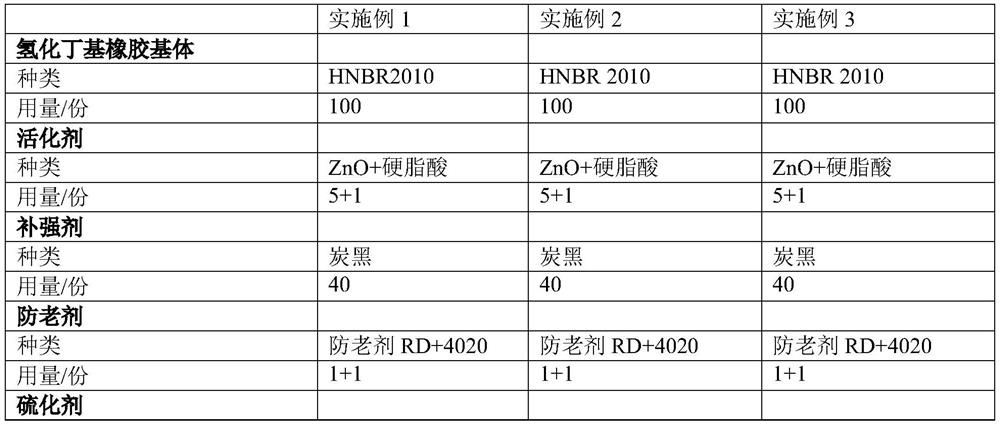

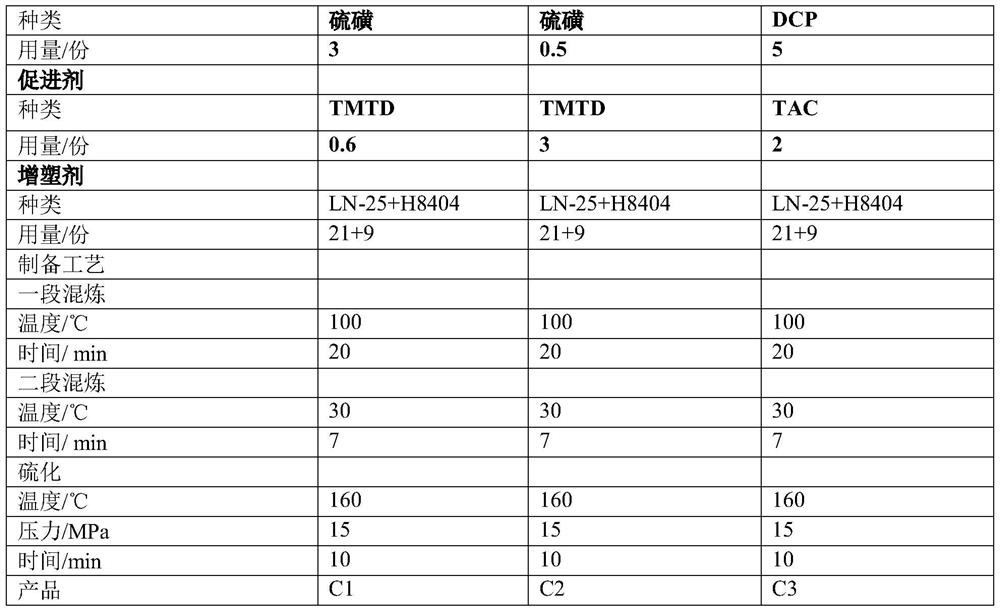

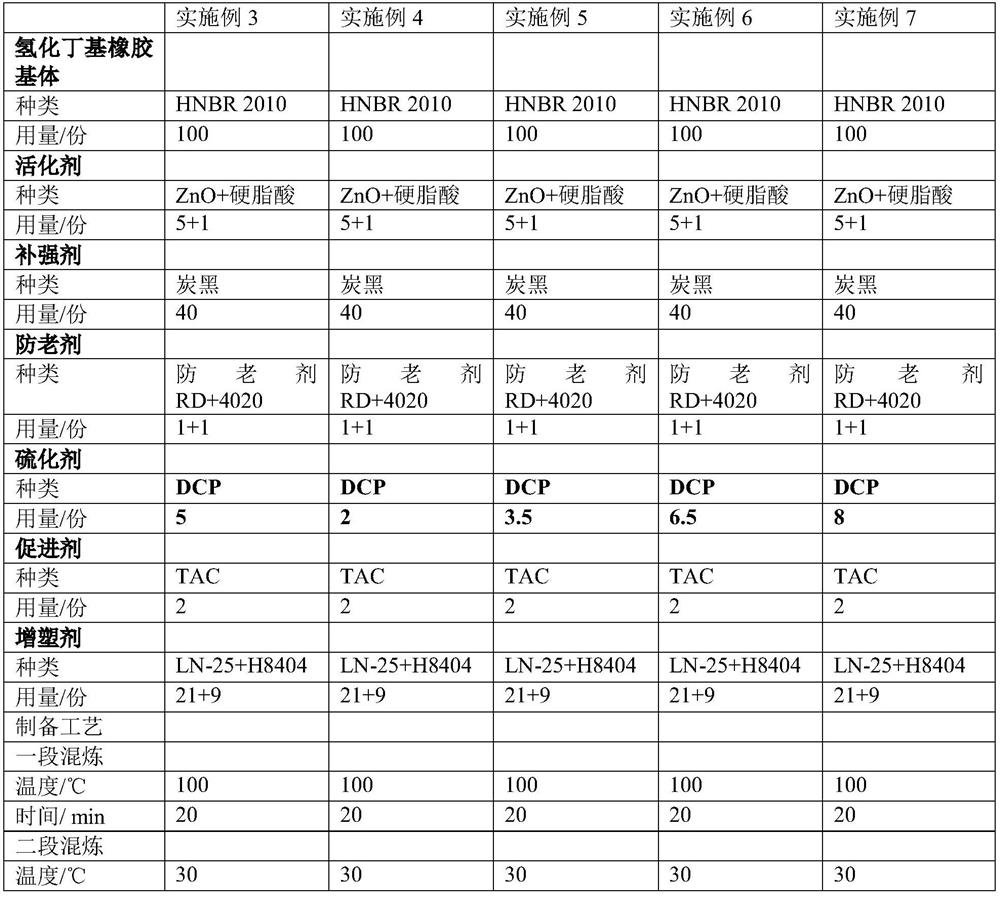

Embodiment 1

[0094] The formula of vulcanization composition is shown in Table 1;

[0095] The preparation process of vulcanized rubber is as follows

[0096] (1) Component A is carried out one-stage mixing, obtains masterbatch, contains hydrogenated nitrile butadiene rubber matrix, activator, reinforcing agent, plasticizer and anti-aging agent in the described component A; The one-stage mixing Conditions include: the mixing temperature is 100°C, and the mixing time is 20 minutes;

[0097] (2) Perform two-stage mixing of the masterbatch and component B, the component B contains an accelerator and a vulcanizing agent, the conditions of the two-stage mixing include: the mixing temperature is 30°C, and the mixing temperature is 30°C. Refining time is 7min;

[0098] (3) Vulcanize the mixed rubber obtained in step (2) in a flat vulcanizer to obtain hydrogenated nitrile rubber C1. The conditions for the vulcanization at least meet: temperature is 160° C., pressure is 15 MPa, and time is 10 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com