Preparation method of magnetic nano-modified methacrylate magnetic impregnating agent for metal casting

A methacrylate and magnetic nanotechnology, applied in the field of composite impregnants, can solve the problems of large differences, low density, poor heat resistance, etc., and achieve the effect of improving oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

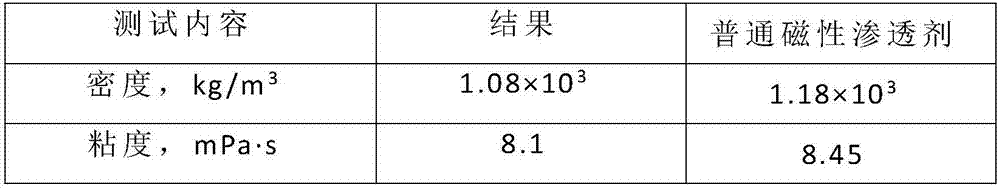

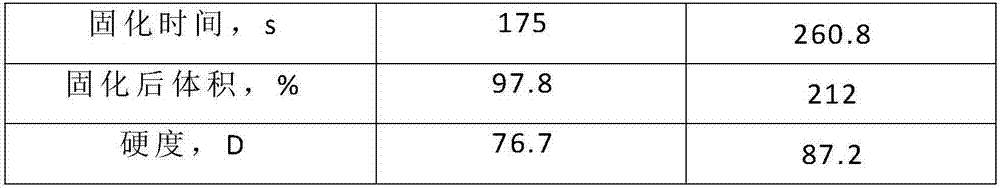

Examples

Embodiment 1

[0023] (1) Using 1 kg of nano-ferric oxide as raw material, add 0.5 kg of hydrochloric acid, react at 30 ° C for 2 h, use 2 kg of ammonia water as a precipitant, add 3 kg of n-dodecane, react at 60 ° C for 1 h, add 0.6 kg of oleic acid, 0.02kg of 3-oxo-1-cyclopentane carboxylic acid, 0.02kg of histamine phosphate, 0.01kg of tetrakis hydroxymethylphosphorus sulfate, reaction temperature 70℃, reaction time 2h, product oil and water separation, dehydration and drying, obtained Stable suspensions containing magnetic nanoparticles;

[0024] (2) Take 1kg of the stable suspension of the above step (1), 2kg of propyl methacrylate, and 0.028kg of benzoyl peroxide, the stirring speed is 100rpm, the temperature is 60°C, the air pressure is 0.5atm, and the reaction time is 1h, add Anionic polyacrylamide 0.01kg, lauryl sulfate ammonium salt 0.05kg, sorbitol 0.04kg, pinacol 0.05kg, stirred and reacted at 70°C for 2 hours to obtain a modified suspension;

[0025] (3) After the suspension to...

Embodiment 2

[0029] (1) Take 1 kg of ferric oxide as raw material, add 2 kg of hydrochloric acid, react at 30 ° C for 2 h, use 5 kg of ammonia water as a precipitant, add 4 kg of propane, react at 100 ° C for 1 h, add 0.8 kg of oleic acid, 3-oxo- 0.06kg of 1-cyclopentane carboxylic acid, 0.07kg of histamine phosphate, 0.03kg of tetrakis hydroxymethyl phosphorus sulfate, reaction temperature 70 ℃, reaction time 3h, product oil and water separation, dehydration and drying, prepared magnetic nanoparticles stable suspension;

[0030] (2) Take 2kg of the stable suspension of the above step (1), 3kg of butyl methacrylate, 0.04kg of cumene hydroperoxide, the stirring speed is 200rpm, the temperature is 60°C, the air pressure is 0.5atm, and the reaction time is 1h. Add 0.02kg of anionic polyacrylamide, 0.07kg of ammonium lauryl sulfate, 0.06kg of sorbitol, and 0.08kg of pinacol, and stir at 70°C for 2 hours to obtain a modified suspension;

[0031](3) After the suspension to be modified is cooled...

Embodiment 3

[0035] (1) Using 1 kg of nano-titanium dioxide as raw material, add 1.25 kg of hydrochloric acid, react at 30 ° C for 2 h, use 3.5 kg of ammonia water as a precipitant, add 3.5 kg of n-hexane, react at 80 ° C for 1 h, add 0.7 kg of oleic acid, 3-oxo Dai-1-cyclopentane carboxylic acid 0.04kg, histamine phosphate 0.045kg, tetrakis hydroxymethyl phosphorus sulfate 0.02kg, reaction temperature 70 ℃, reaction time 2.5h, product oil and water separation, dehydration and drying, prepared magnetic stable suspension of nanoparticles;

[0036] (2) Take 1.5kg of the stable suspension of the above step (1), 2.5g of methacrylate monomer, 0.034kg of tert-butyl peroxytoluate, stir at 150rpm, temperature at 60°C, and air pressure at 0.5atm , reaction time 1h, add anionic polyacrylamide 0.015kg, lauryl sulfate ammonium salt 0.06kg, sorbitol 0.05kg, pinacol 0.065kg, stir and react at 70°C for 2h to obtain a modified suspension;

[0037] (3) After the suspension to be modified is cooled, add 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com