Special shoemaking device and process for processing leather shoes

A special technology for making leather shoes, applied in shoemaking machinery, footwear, applications, etc., can solve the problems of uniform heat distribution, heat accumulation, low temperature, etc., to improve heat absorption efficiency, speed up flow speed, and improve drying efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

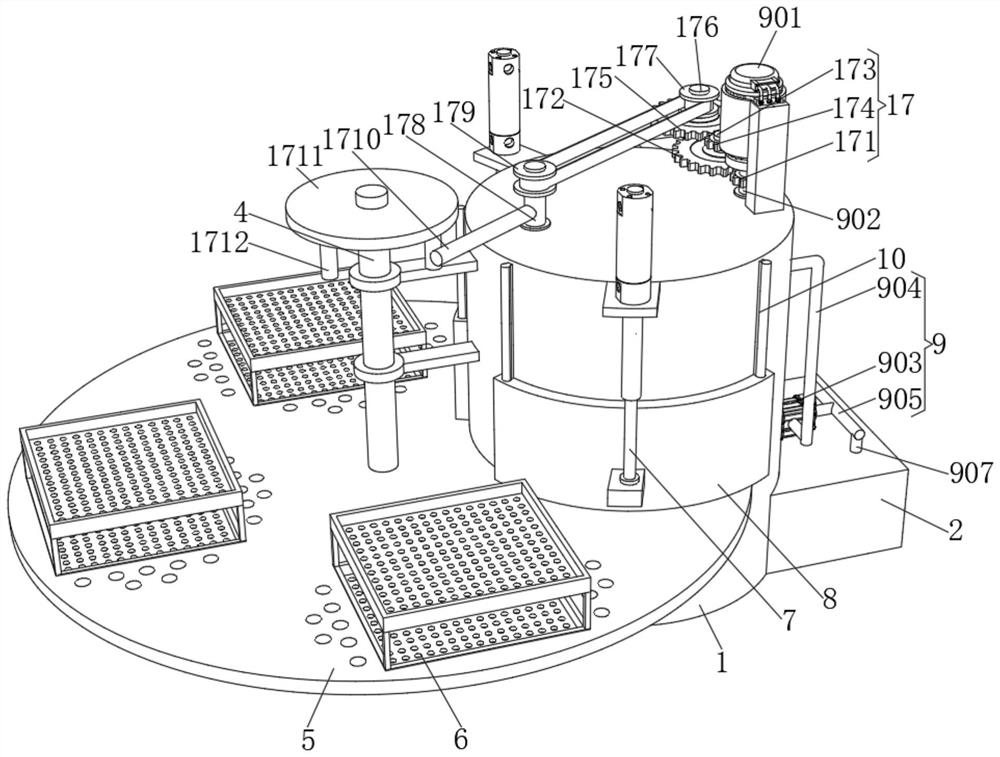

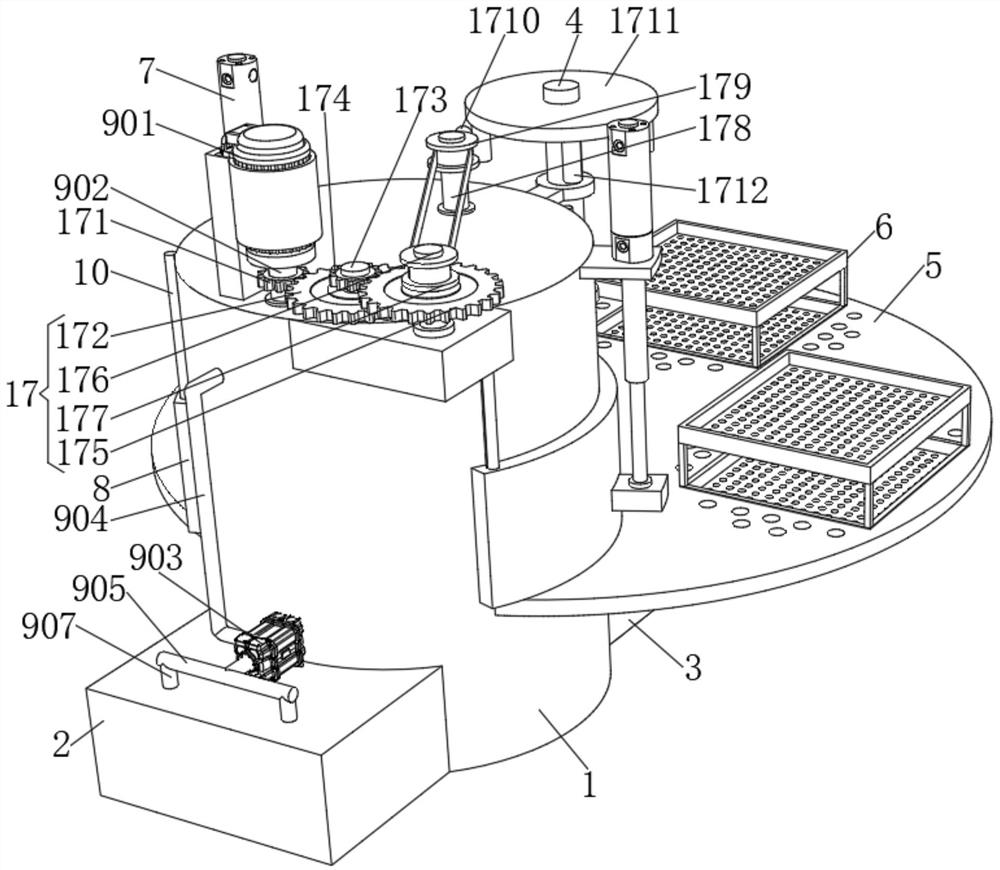

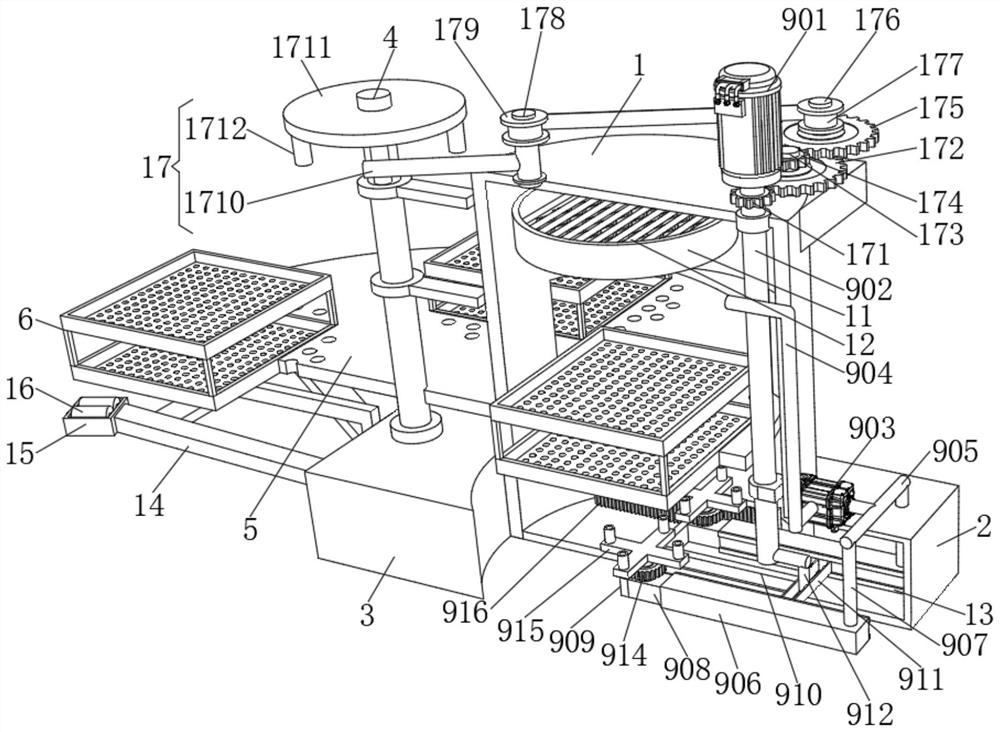

[0032] see Figure 1-6 , the present invention provides a technical solution: a special shoe-making device for processing leather shoes, including a heating tank 1, the bottom of both sides of the heating tank 1 is provided with a base 3 and an auxiliary box 2 in sequence along the left and right directions, and the heating tank 1 and the auxiliary box 2 are connected to each other. The adjacent side is connected, and the top of the inner cavity of the heating tank 1 is fixedly connected with a protective cover 11. There are multiple sets of heating wires 12 fixedly connected in the protective cover 11 along the left and right directions, which can provide a heating source for the heating tank 1. An auxiliary mechanism 9 is provided. The design of the auxiliary mechanism 9 facilitates the introduction of heat from the upper layer to the lower layer, so that the temperature of the upper, middle and lower parts of the heating tank 1 can be quickly kept consistent, and at the same...

Embodiment 2

[0034] see Figure 1-6 , the present invention provides a technical solution: a special shoe-making device for processing leather shoes, including a heating tank 1, the bottom of both sides of the heating tank 1 is provided with a base 3 and an auxiliary box 2 in sequence along the left and right directions, and the heating tank 1 and the auxiliary box 2 are connected to each other. The adjacent side is connected, and the top of the inner cavity of the heating tank 1 is fixedly connected with a protective cover 11. There are multiple sets of heating wires 12 fixedly connected in the protective cover 11 along the left and right directions, which can provide a heating source for the heating tank 1. An auxiliary mechanism 9 is provided, the auxiliary mechanism 9 includes a motor 901, the motor 901 is fixedly connected to the heating tank 1 through a mounting bracket, the right side of the heating tank 1 bottom is rotatably connected with a fixed shaft 902 through a sealed bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com