Wafer structure

A wafer and chip technology, applied in printing, inking devices, etc., can solve problems such as waste, ineffective reduction of manufacturing costs, waste of blank area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Embodiments embodying the features and advantages of this case will be described in detail in the description of the latter paragraph. It should be understood that the present case can have various changes in different aspects without departing from the scope of the present case, and the descriptions and diagrams therein are used for illustration in nature rather than limiting the present case.

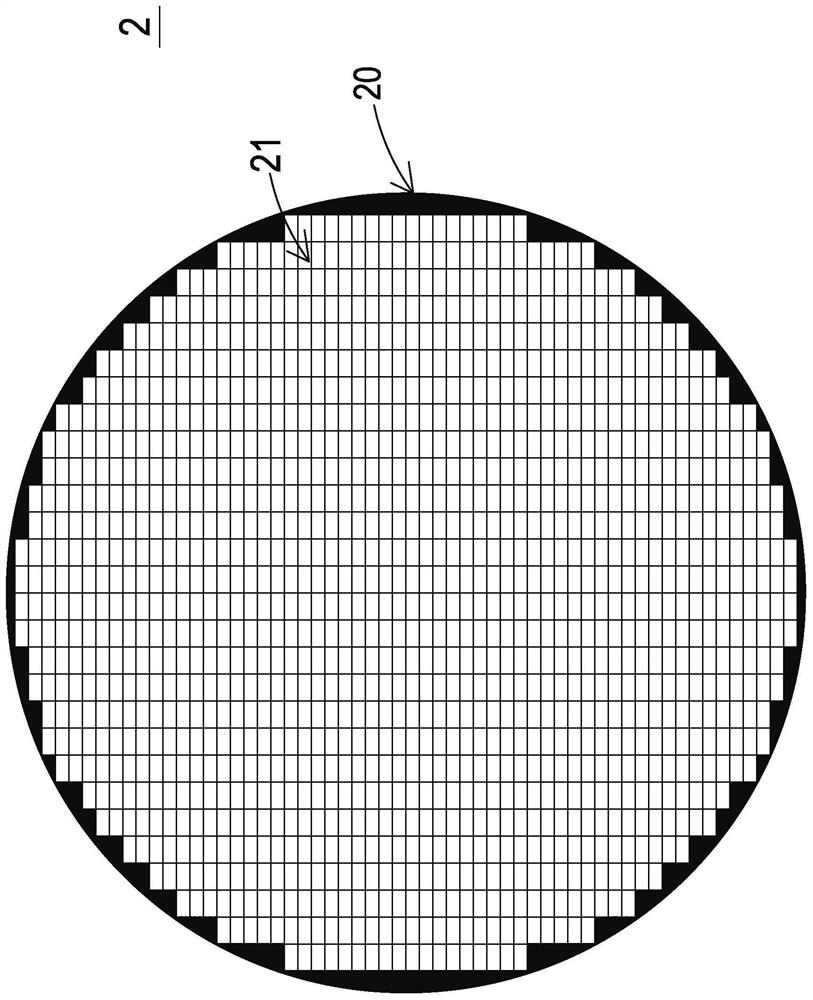

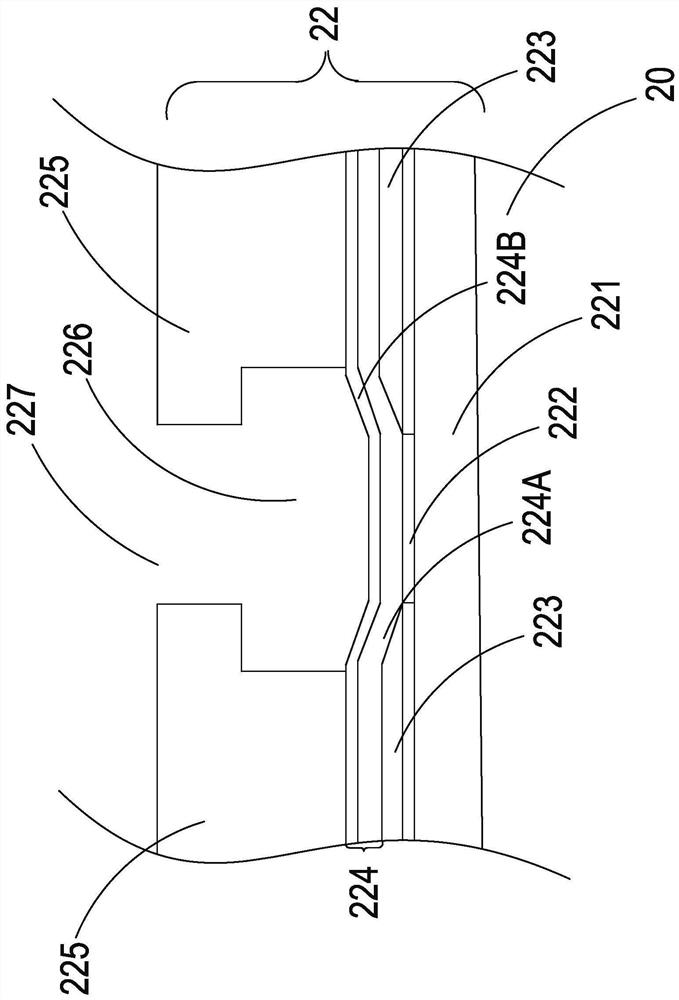

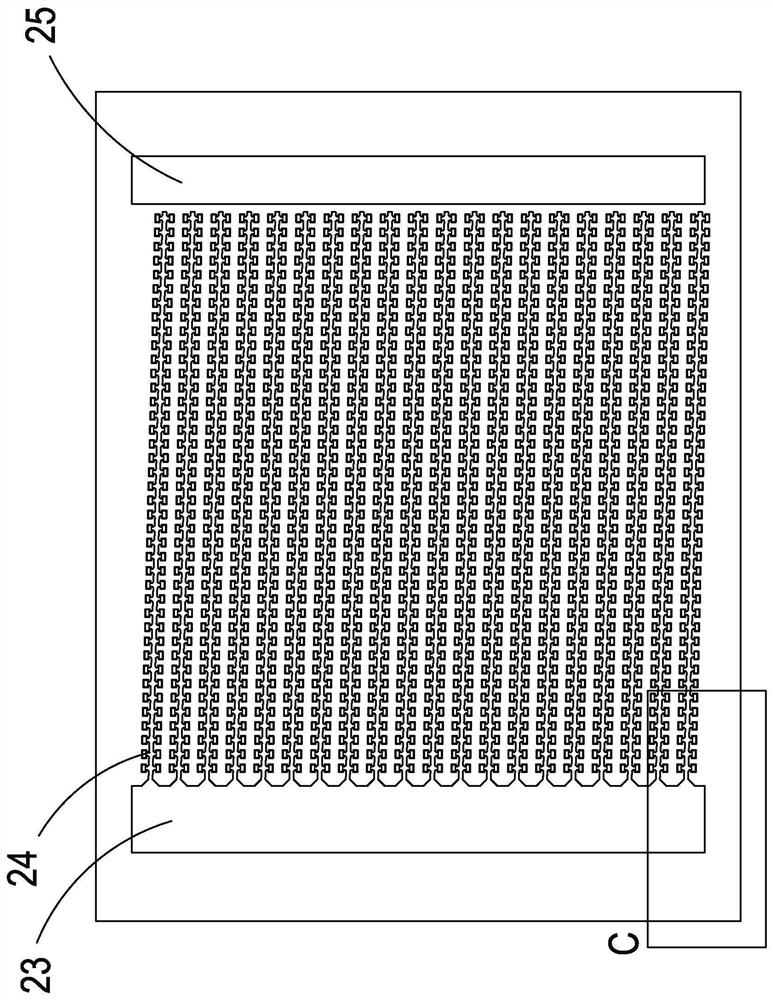

[0063] see figure 1 and figure 2 As shown, the present application provides a wafer structure 2 including: a chip substrate 20 and a plurality of inkjet chips 21 . Wherein the chip substrate 20 is a silicon base material, which is manufactured by a semiconductor manufacturing process of a wafer of at least 12 inches (inch). In a specific embodiment, the chip substrate 20 can be manufactured using a semiconductor manufacturing process of a 12-inch (inch) wafer; or, in another specific embodiment, the chip substrate 20 can be manufactured using a semiconductor process of a 16-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com