Method for preparing sec-butylamine from etherified C4

A technology after sec-butylamine and ether, applied in the field of preparing sec-butylamine, can solve problems such as unseen, achieve simple separation process and solve the effect of overcapacity of acetic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

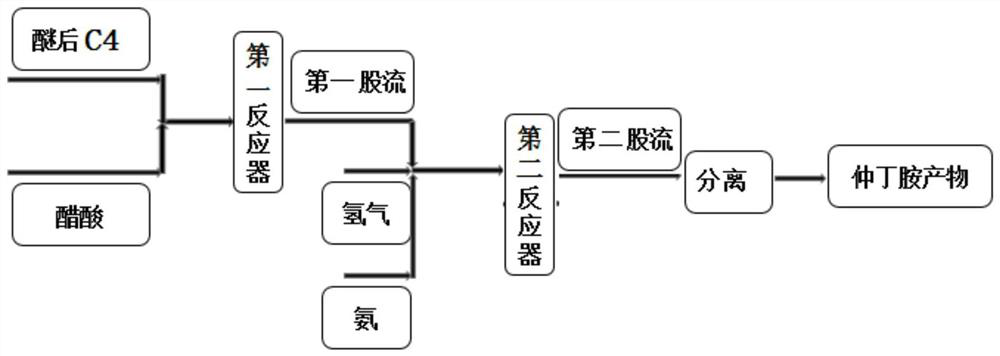

Method used

Image

Examples

Example Embodiment

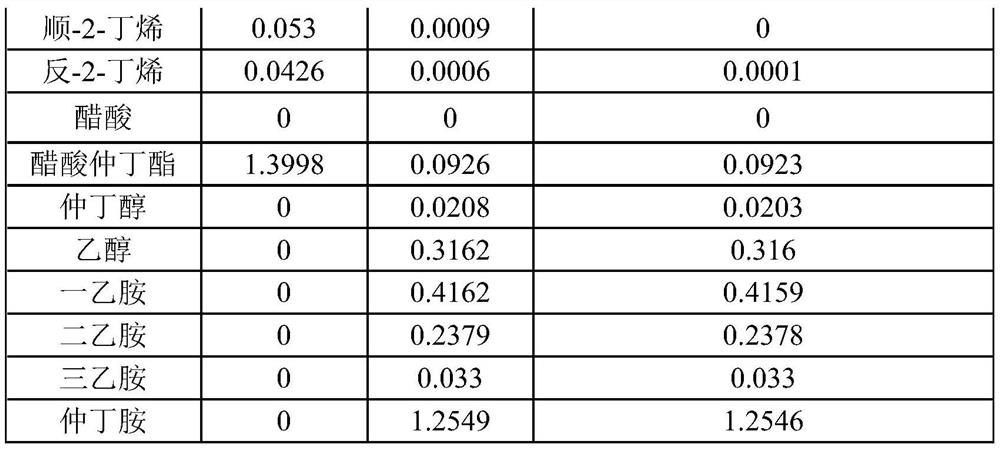

[0036] Example 1

[0037] This example provides a method for preparing sec-butylamine by C4 after ether.

[0038] The first catalyst is the macroporous sulfonic acid cation exchange resin produced by Dandong Mingzhu Special Resin Co., Ltd.

[0039] The preparation method of the second catalyst is as follows:

[0040] (1) Carrier molding: take 300g of alumina powder and 6g of scallop powder and mix them in a kneader. Add 270mL of water, knead for 20min, then extrude into a 3mm thick clover shape with an extruder, dry at 120°C, and then bake at 800°C for 4 hours to obtain an alumina carrier.

[0041] (2) Loading active components: take 188.1g of Co(NO 3 ) 2 ·6H 2 O (industrial grade, purity 98%), 54.31g of Zn (NO 3 ) 2 ·6H 2 O (analytical pure) was dissolved in water into 180mL solution, and the above solution was loaded on the obtained 100g carrier by spraying twice; after each spraying, it was dried at 120°C for 4 hours, and then roasted at 390°C for 4 hours. hours, t...

Example Embodiment

[0055] Example 2

[0056] This example provides a method for preparing sec-butylamine by C4 after ether.

[0057] The first catalyst is the macroporous sulfonic acid cation exchange resin produced by Dandong Mingzhu Special Resin Co., Ltd.

[0058] The preparation method of the second catalyst is as follows:

[0059] (1) Carrier molding: take 300g of alumina powder and 6g of scallop powder and mix them in a kneader. Add 270mL of water, knead for 20min, then extrude into a 3mm thick clover shape with an extruder, dry at 120°C, and then bake at 800°C for 4 hours to obtain an alumina carrier.

[0060] (2) Loading active components: take 271.4g of Co(NO 3 ) 2 ·6H 2 O (technical grade, purity 98%) is dissolved in water to be 176mL solution, and above-mentioned solution is loaded on the obtained 100g carrier with spray dipping method twice; The catalyst was calcined at ℃ for 4 hours to obtain the catalyst in the oxidized state. (3) Reduction of the catalyst in the oxidized st...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap