High-temperature fast-firing shuttle-type kiln

A shuttle and kiln technology, applied in the directions of furnaces, furnace types, furnace components, etc., can solve the problems of uneven heating, increased temperature difference, aggravated furnace gas stratification, etc., to achieve uniform heating and improve quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following is attached Figure 1-7 The application is described in further detail.

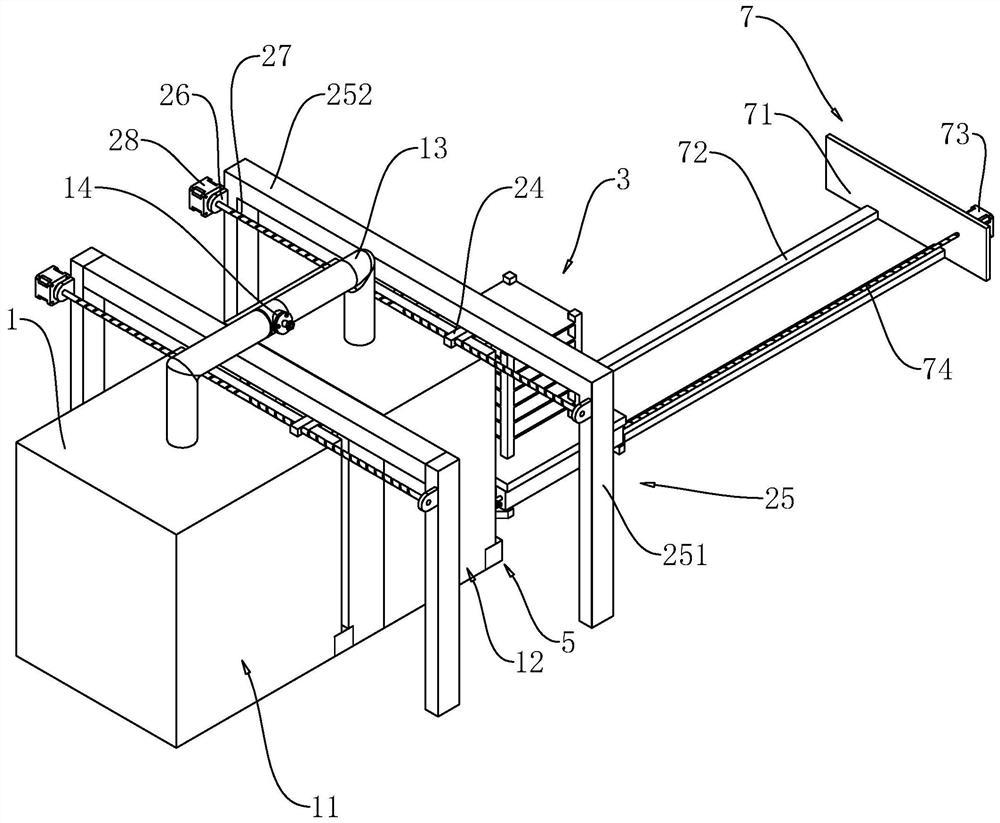

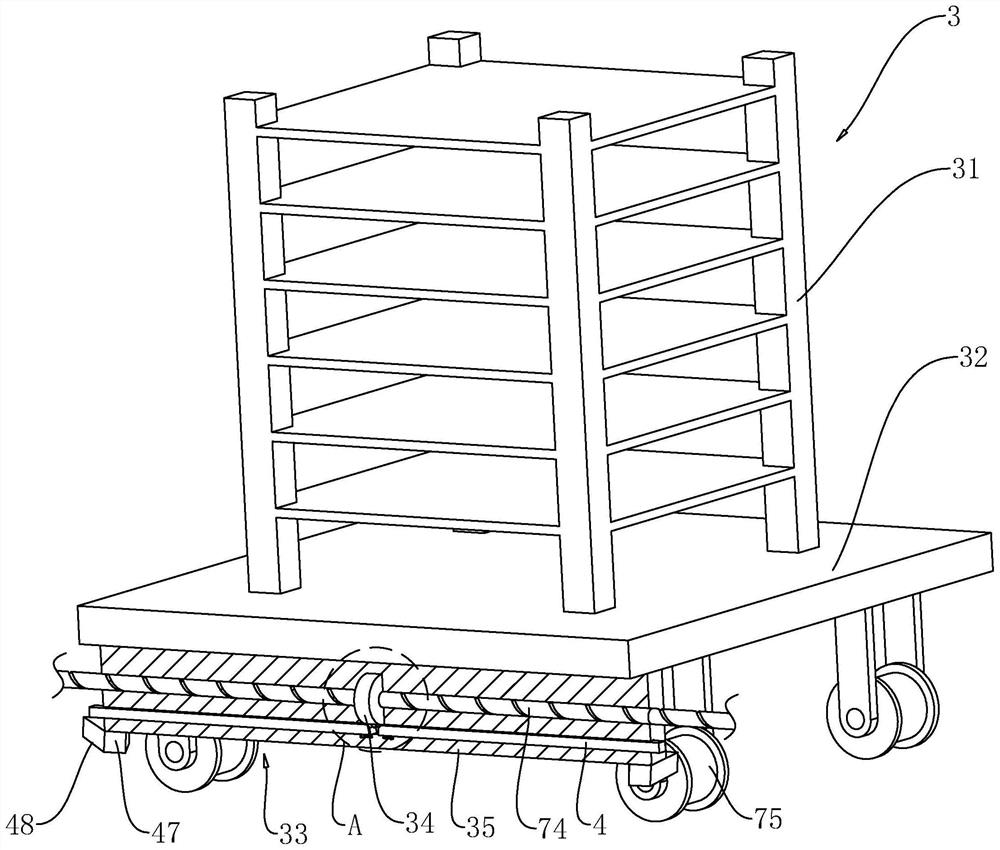

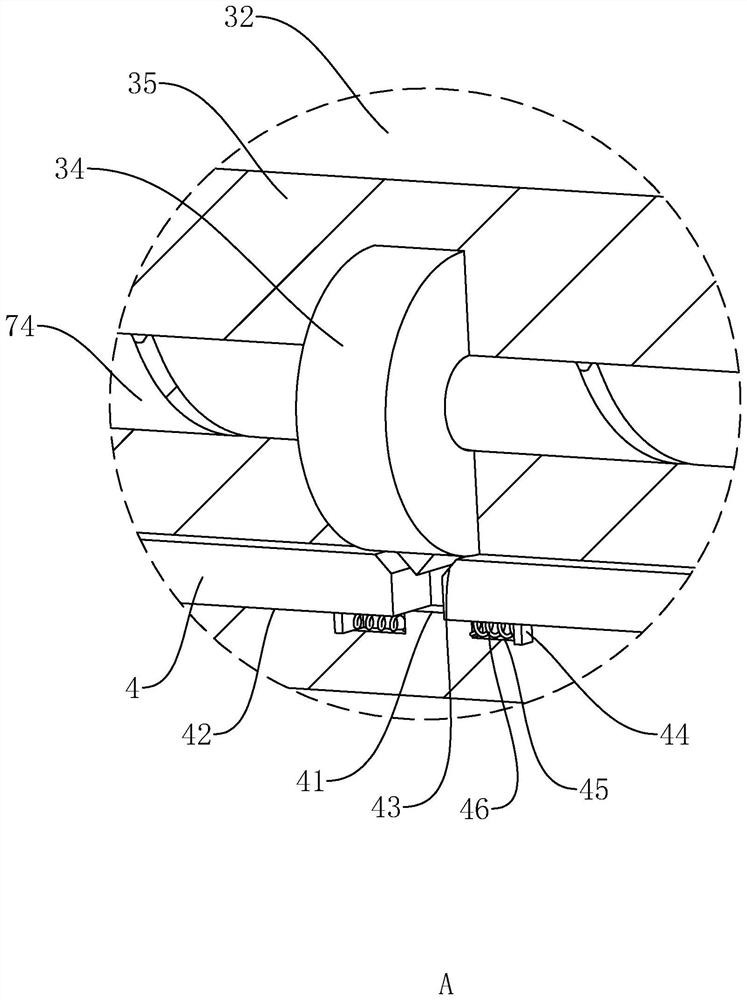

[0036] The embodiment of the present application discloses a high-temperature fast-firing shuttle kiln. refer to figure 1 , The high-temperature fast-firing shuttle kiln includes a kiln body 1 for firing ceramics, a kiln car 3 for carrying ceramics, and a driving device 7 for driving the kiln car 3 to move. The kiln body 1 includes a firing chamber 11 and a preheating chamber 12 , and a kiln door 2 is provided on the side of the firing chamber 11 and the preheating chamber 12 close to the kiln car 3 . A communication pipe 13 is fixed on the top surface of the firing chamber 11 , the other end of the communication pipe 13 is fixedly connected with the top surface of the preheating chamber 12 , and a valve 14 is fixed on the communication pipe 13 .

[0037] refer to figure 1 with figure 2 The driving device 7 includes a slide rail 72 fixed on the ground and arranged along the len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com