Method for separating initiator and body of dangerous initiating explosive device assembly

A separation method and technology for pyrotechnics, which are used in electrical components, weapon accessories, offensive equipment, etc., can solve the problem of inability to safely separate dangerous pyrotechnic assemblies, and achieve safe release, risk reduction, and accident prevention. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

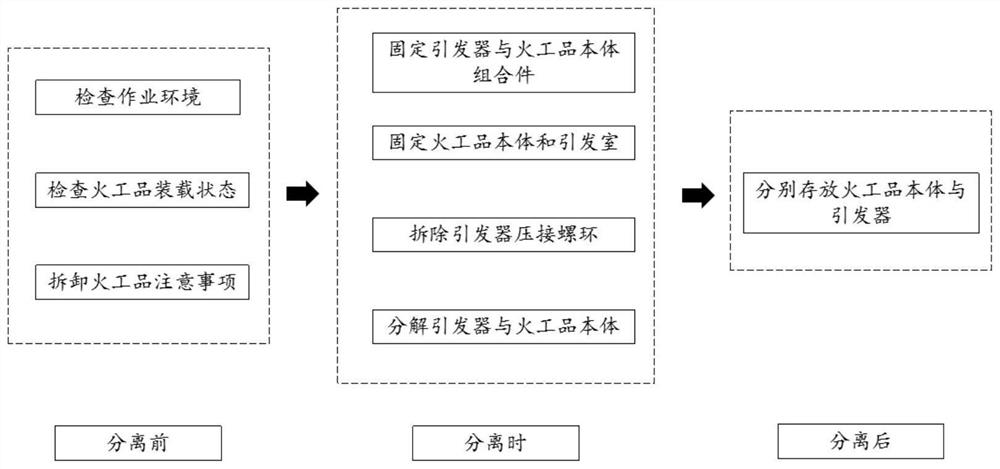

[0088] This embodiment provides a separation method for the separation of dangerous pyrotechnics assemblies, including the following steps:

[0089] Step 1. Fix the dangerous pyrotechnics assembly;

[0090] Hoist the dangerous pyrotechnics assembly on the anti-static workbench, and fix the dangerous pyrotechnics assembly with the support seat of the dangerous pyrotechnics body.

[0091] In step 1, the dangerous pyrotechnic body support seat includes a first arc-shaped fixing seat and a second arc-shaped fixing seat with the same structure, parallel to each other and connected, the first arc-shaped fixing seat and the second arc-shaped fixing seat The line connecting the center of the circular fixed seat is parallel to the axis of the cylindrical dangerous pyrotechnics body; the two ends of the first arc-shaped fixed seat and the second arc-shaped fixed seat are connected to the dangerous pyrotechnics body through the pull rod provided. The lugs on the outer surface are detach...

Embodiment 2

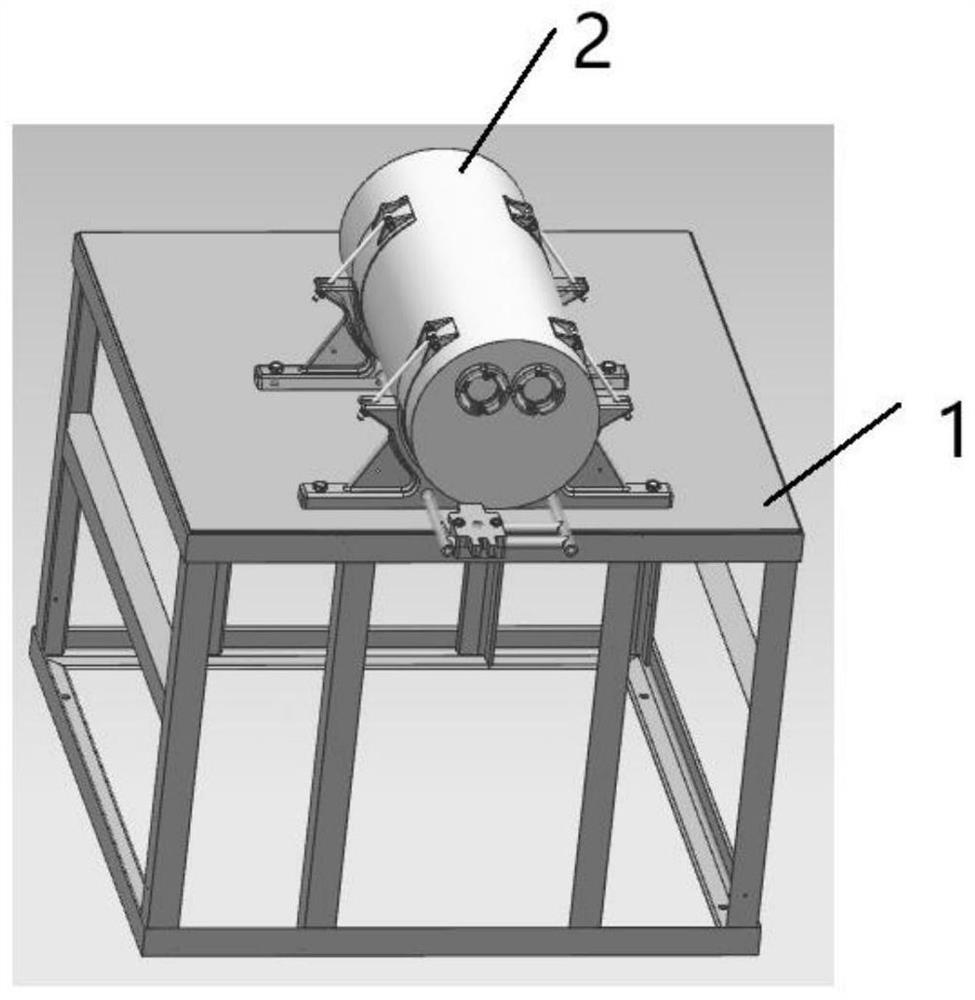

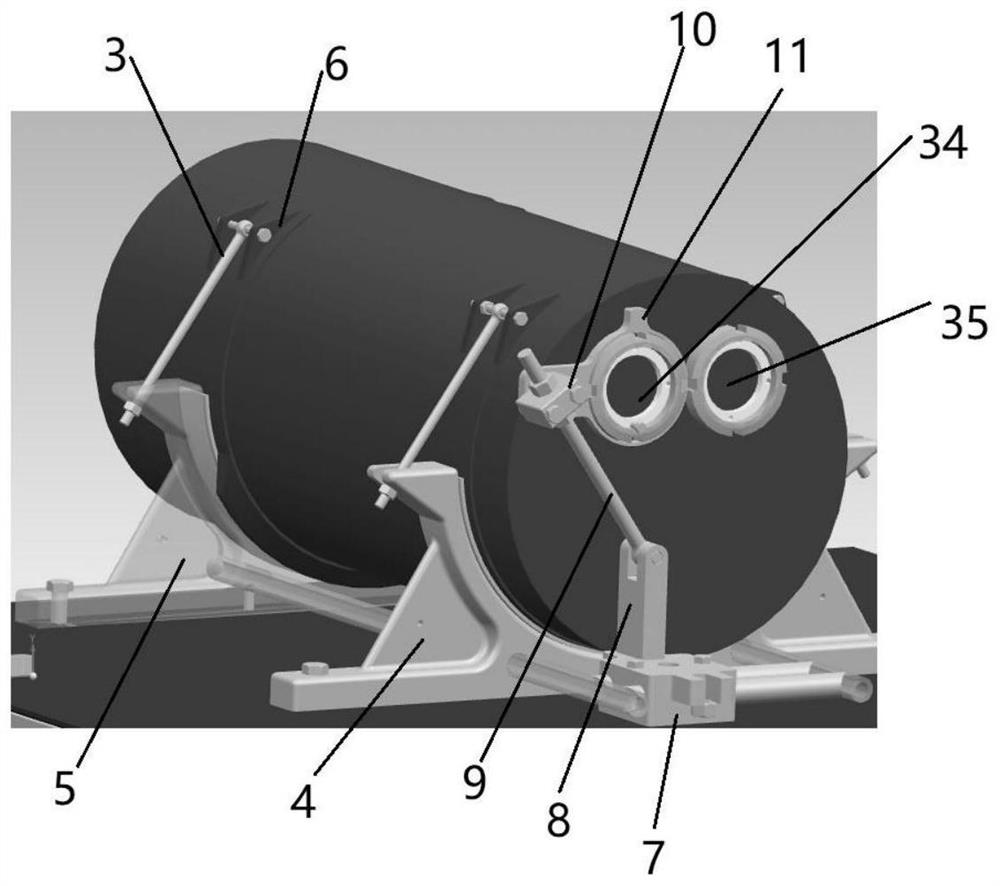

[0103] Example 2 as Figure 2 to Figure 5 As shown, the present invention provides a separation device for the separation of dangerous pyrotechnics assemblies, which is used to realize the safety control process of the above-mentioned separation of dangerous pyrotechnics assemblies. The separation device includes an initiation chamber fixing mechanism and a crimping screw ring Disassembly mechanism; the dangerous pyrotechnics assembly includes the dangerous pyrotechnics body 2 and the first initiator 34; the dangerous pyrotechnics body 2 is cylindrical; the first initiator 34 is arranged on the first end surface of the dangerous pyrotechnics body 2 Above; the first initiator 34 is located in the first initiating chamber 22, the first initiating chamber 22 is a hollow cylinder with one end open, and the first initiating chamber 22 is covered with a cylindrical first fastening screw ring 21; the first The opening of the initiation chamber 22 is provided with a first crimping spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com