Horizontal pulverized coal fiber separator

A fiber separation and pulverized coal technology, applied in the direction of solid separation, chemical instruments and methods, grids, etc., can solve the problems of blocked pneumatic conveying pipelines, falling out of the fiber separation port, affecting the stable production and operation of the system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is further described and understood by non-limiting examples below.

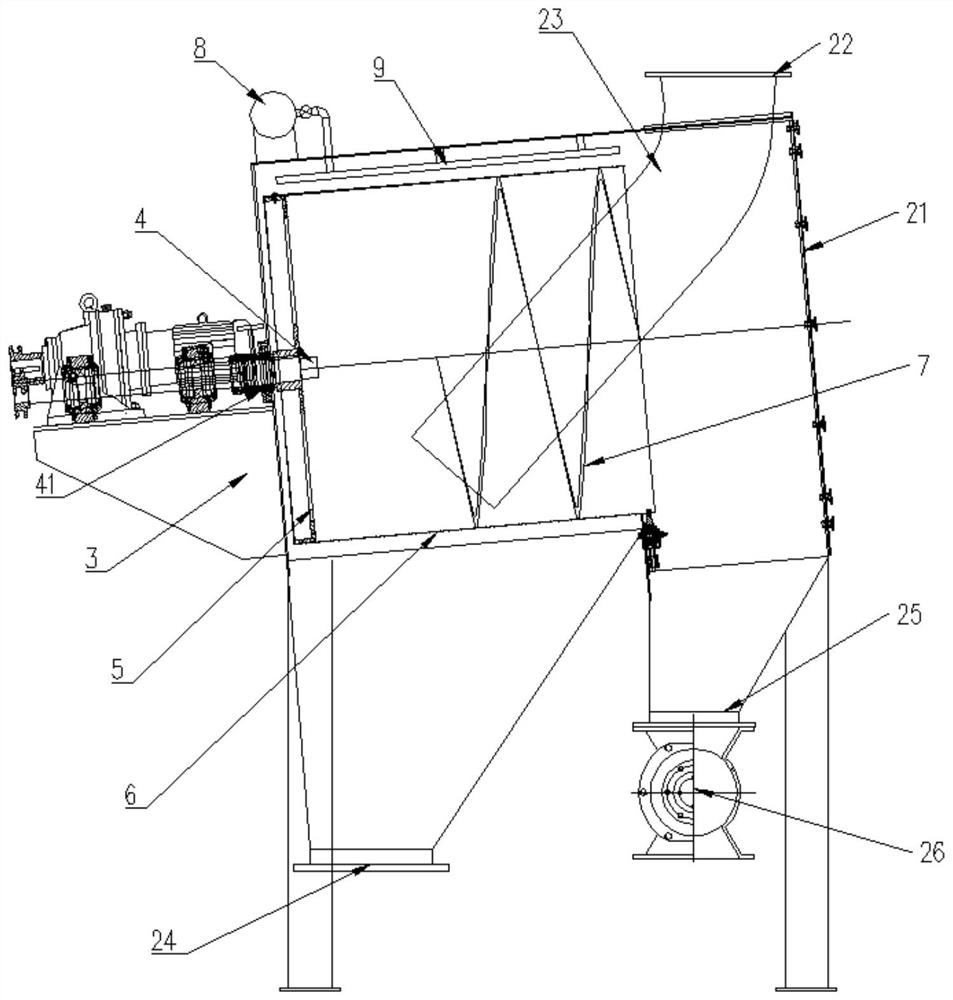

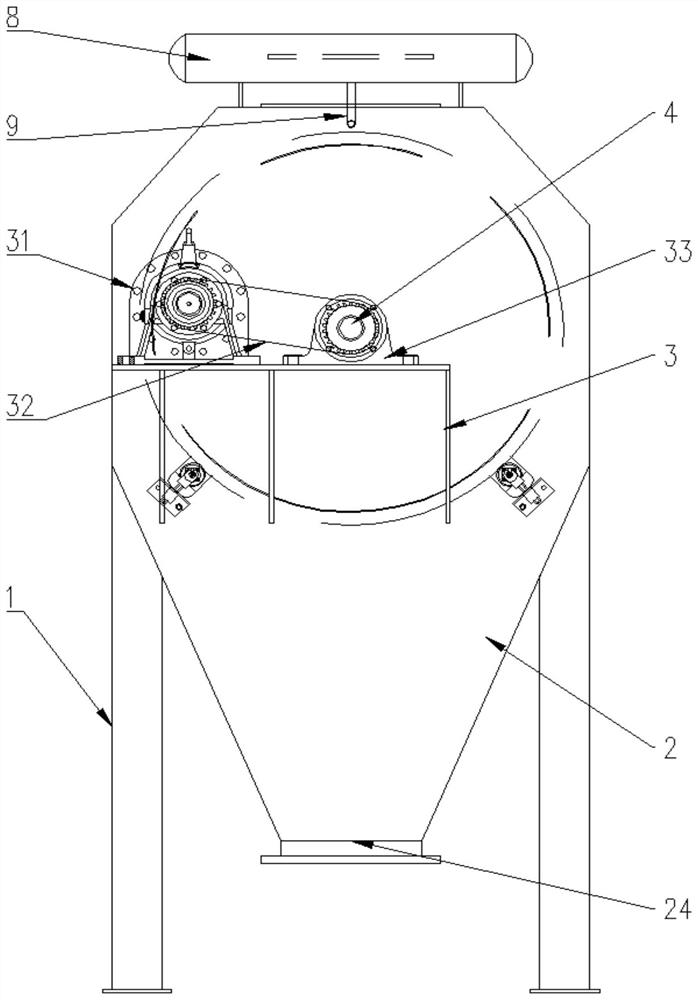

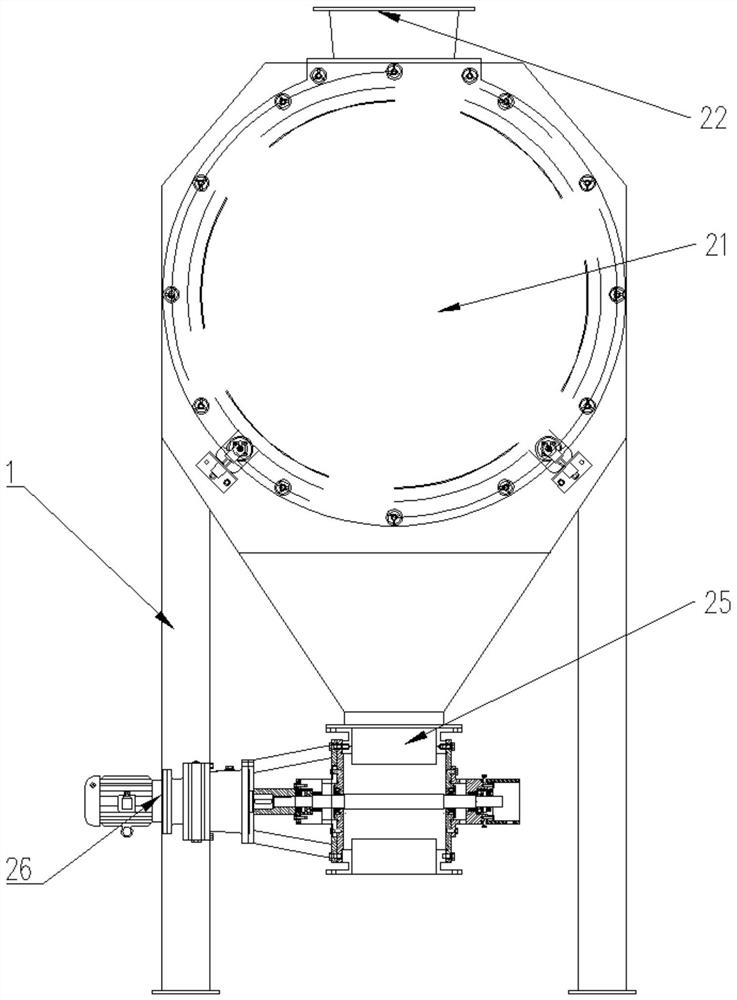

[0014] Such as Figure 1-3 As shown, the present invention provides a horizontal pulverized coal fiber separator, comprising a housing 2 arranged on a frame 1, a driving frame 3 is arranged at the front end of the housing 2, a driving assembly is arranged on the driving frame 3, and the housing The rear end of the body 2 is fixedly installed with a rear cover assembly 21, and the central part of the housing 2 is provided with a transmission shaft 4 from the front end to the rear end. The transmission shaft 4 is driven by a drive assembly, which includes a drive shaft 4 The bearing assembly 33 installed on the driving frame 3 is connected to the driving motor 31 of the bearing assembly 33 through the transmission belt 32 . The drive motor 31 transmits power to the bearing assembly 33 through the conveyor belt, and the bearing assembly 33 transmits the power to the screen frame 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com