Single-color gradient film and preparation method, cover plate, device and application thereof

A color gradient and cover plate technology, applied in manufacturing tools, special patterns, decorative arts, etc., can solve the problems of strong color jumps, narrow corresponding bands, and difficult color gradients, and achieve cost reduction and uniform color transitions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

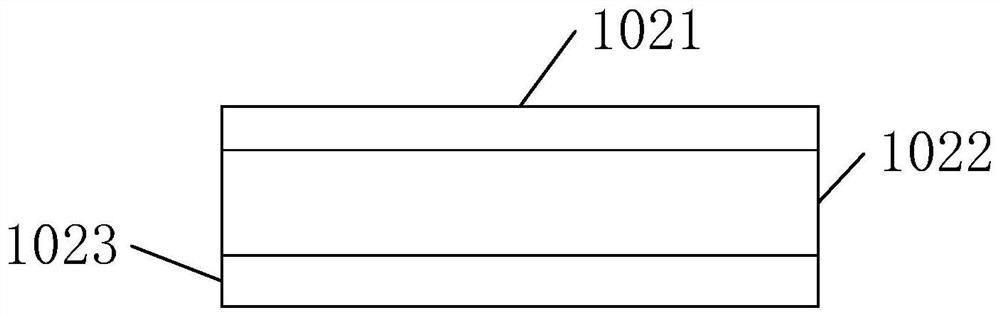

[0060] According to one aspect of the present invention, the present invention relates to a preparation method of a single color gradient film, comprising the following steps:

[0061] S1, coating the surface of the cover plate with a color film to obtain a color-coated cover plate;

[0062] S2, make the color-plated cover plate form a certain inclined angle with the horizontal plane and fix the color-plated cover plate, by pressing down on the polished area of the color-plated cover plate on the color-plated cover plate, and The elastic polishing layer of the polishing tool is rotated to polish the color-plated cover plate, and the rotation axis of the elastic polishing layer is vertical and located on one side of the whole piece of the color-plated cover plate.

[0063] The method of the present invention is the first to obtain a single-color gradient film with excellent effect through physical polishing, by setting the color-coated cover plate at a certain inclined angle ...

Embodiment 1

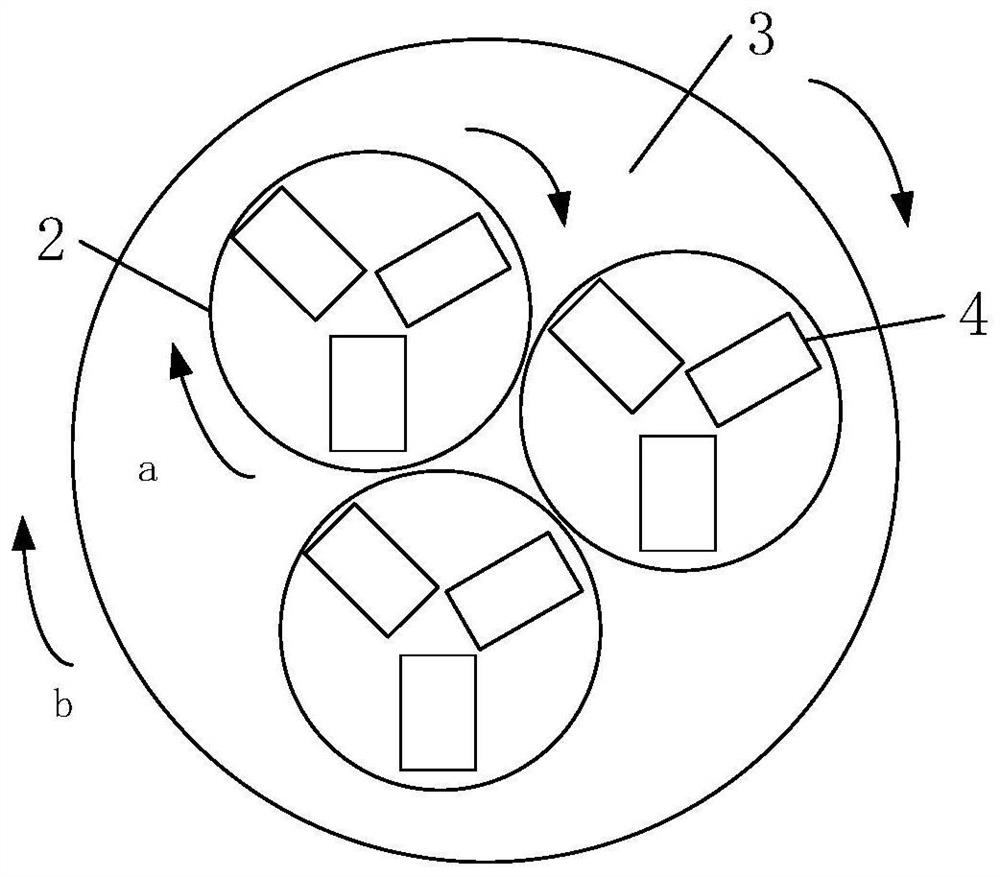

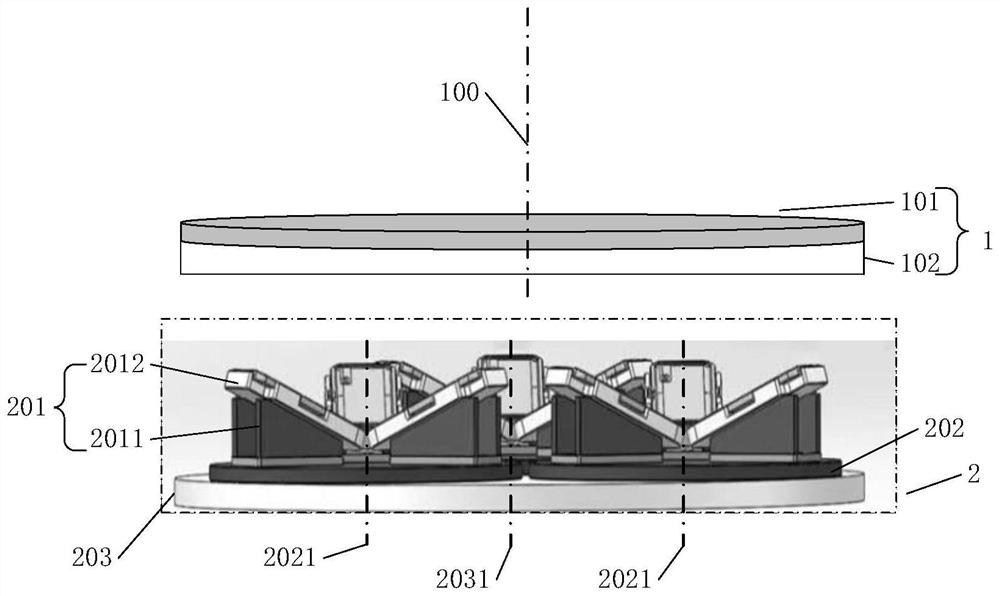

[0116] A polishing device (such as image 3 shown), the device includes a polishing tool 1 and a positioning assembly 2;

[0117] The positioning assembly 2 includes 3 positioning fixtures 201, 3 first turntables 202 and 1 second turntable 203; the positioning assembly 2 has a support surface with a certain inclination angle with the horizontal plane, and the inclination angle of the support surface is 5 degrees The polishing tool 1 includes a disc body 101 and an elastic polishing layer 102 connected to the disc body 101 and facing downward, the elastic polishing layer 102 has a vertically arranged rotation axis 100, and the support surface is located at the rotation axis One side of the horizontal direction of 100; the positioning fixture 201 includes two first members 2011 oppositely arranged, and a second member 2012 connected to the upper ends of the two first members 2011, and the supporting surface is formed on the first member 2011 In the top cavity of the second memb...

Embodiment 2

[0129] A polishing device for preparing a single color gradient film, said device comprising a polishing tool 1 and a positioning assembly 2;

[0130] The positioning assembly 2 includes 6 positioning fixtures 201, 3 first turntables 202 and 1 second turntable 203; the positioning assembly 2 has a support surface with a certain inclination angle to the horizontal plane, and the inclination angle of the support surface is 6.5 degrees The polishing tool 1 includes a disc body 101 and an elastic polishing layer 102 connected to the disc body 101 and facing downward, the elastic polishing layer 102 has a vertically arranged rotation axis 100, and the support surface is located at the rotation axis One side of the horizontal direction of 100; the positioning fixture 201 includes two first members 2011 oppositely arranged, and a second member 2012 connected to the upper ends of the two first members 2011, and the supporting surface is formed on the first member 2011 In the top cavit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com