Ground suction nozzle of electric sweeping appts.

A cleaning and ground technology, applied in the direction of suction nozzles, vacuum cleaners, suction hoses, etc., can solve the problems such as the inability to move the ground suction nozzles at will, difficult operation of the ground suction nozzles, and the inability of the ground suction nozzles to move.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Embodiment of the invention

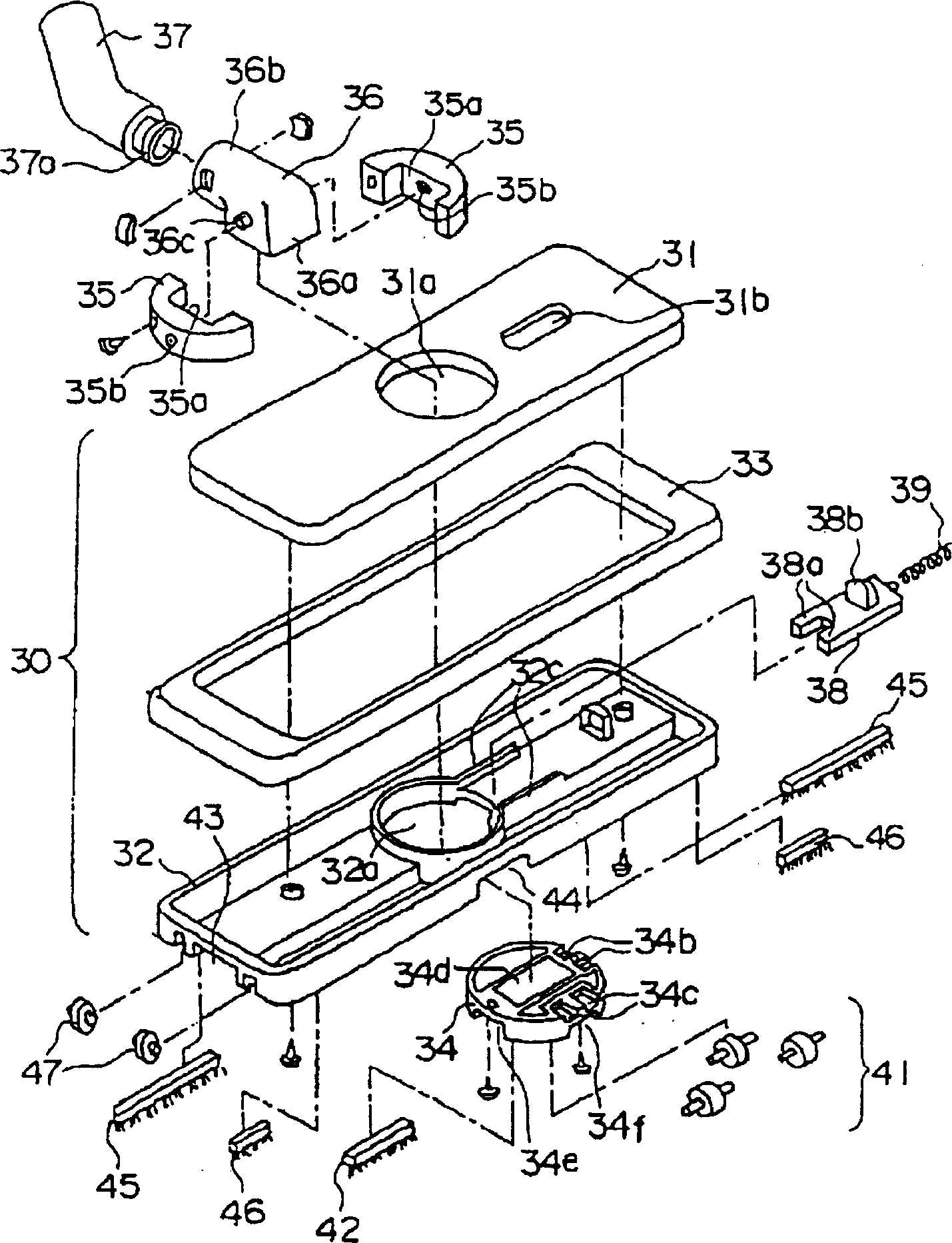

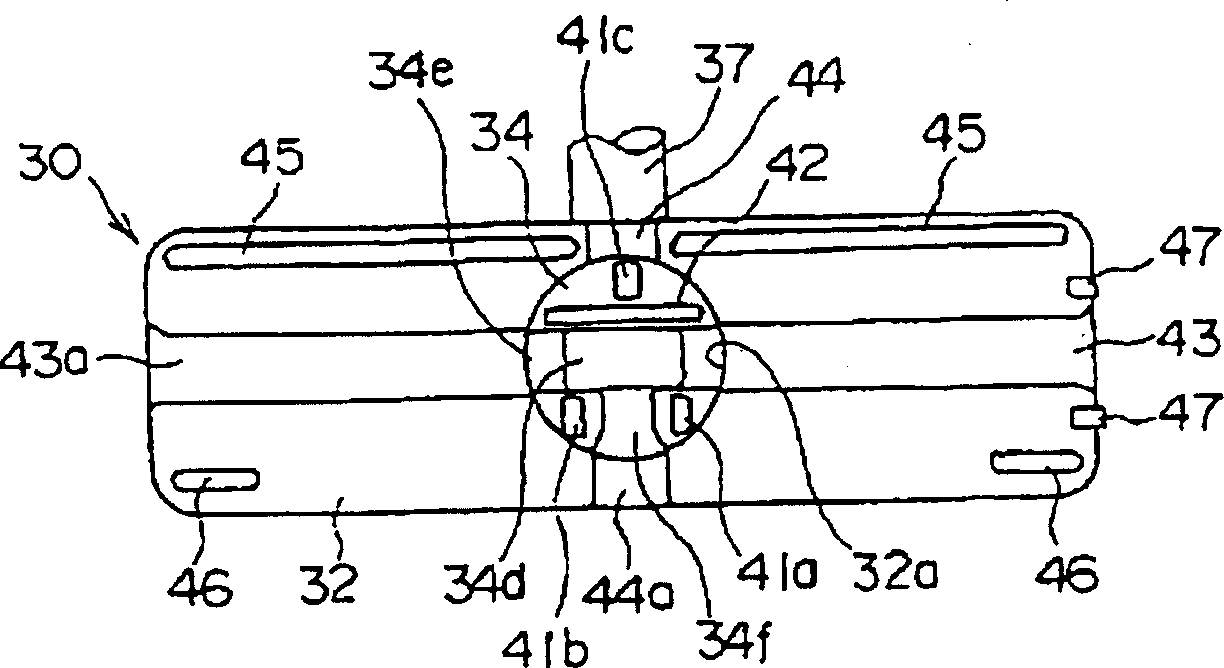

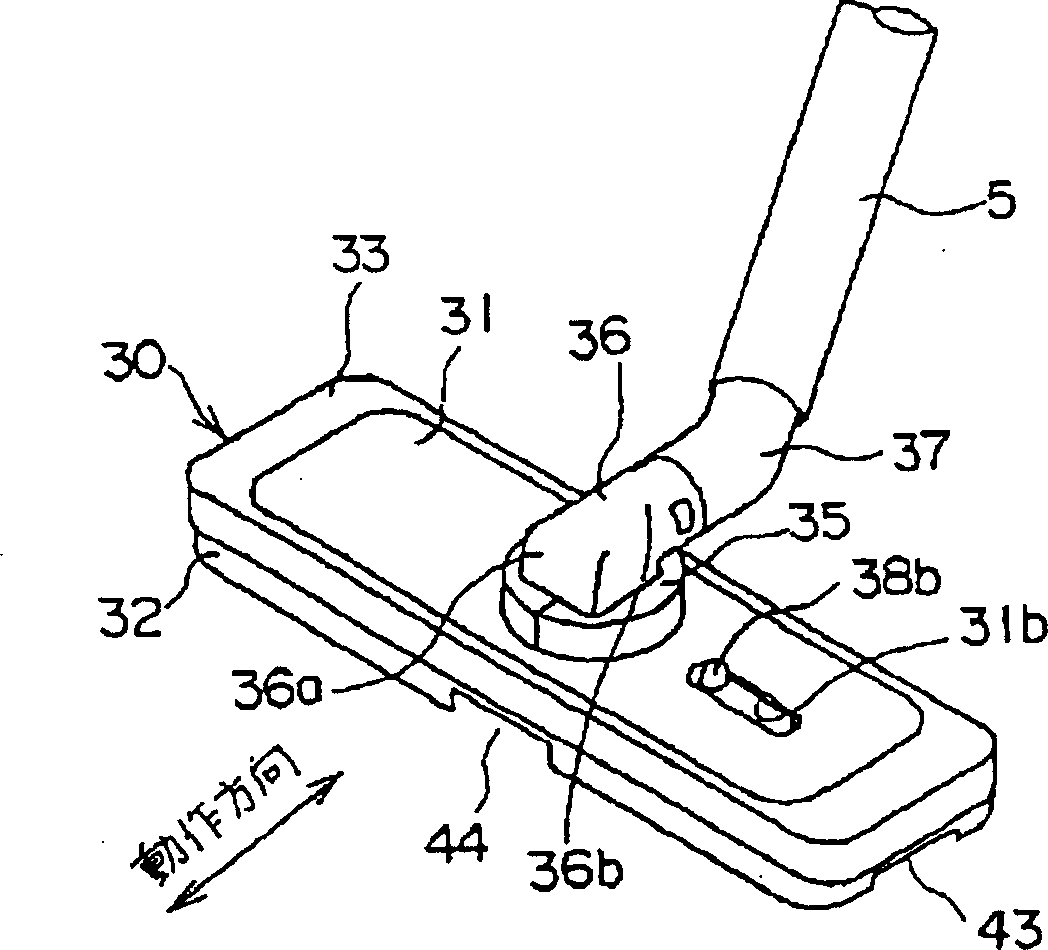

[0061] In each figure, reference numeral 31 is a substantially rectangular upper case, and reference numeral 32 is a similarly substantially rectangular lower case, which are joined together via a shock absorber 33 formed of a soft material, and the upper and lower cases 31, 32 And the shock absorber 33 constitutes the nozzle main body 30 . Reference numeral 34 is a rotating plate that is inserted from below into the holes 31a, 32a provided at approximately the center of the upper and lower housings 31, 32 and installed so as to be horizontally rotatable relative to the nozzle main body 30. By making the flange 34a such as Figure 9 As shown in contact with the stepped portion 32b of the lower housing 32, the depth of insertion from below can be defined. Reference numeral 35 is inserted into the holes 31a, 32a of the upper and lower housings 31, 32 from above so as to be integrated with the rotating plate 34, and is composed of two parts d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com