Hydraulic jacking integral type steel end mold for secondary lining of highway tunnel and construction method of hydraulic jacking integral type steel end mold

An integrated technology for road tunnels, applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of difficult installation and disassembly of end formwork, reduce the construction efficiency of secondary lining, etc., achieve convenient disassembly, not easy to deform, and improve lateral rigidity and the effect of longitudinal stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

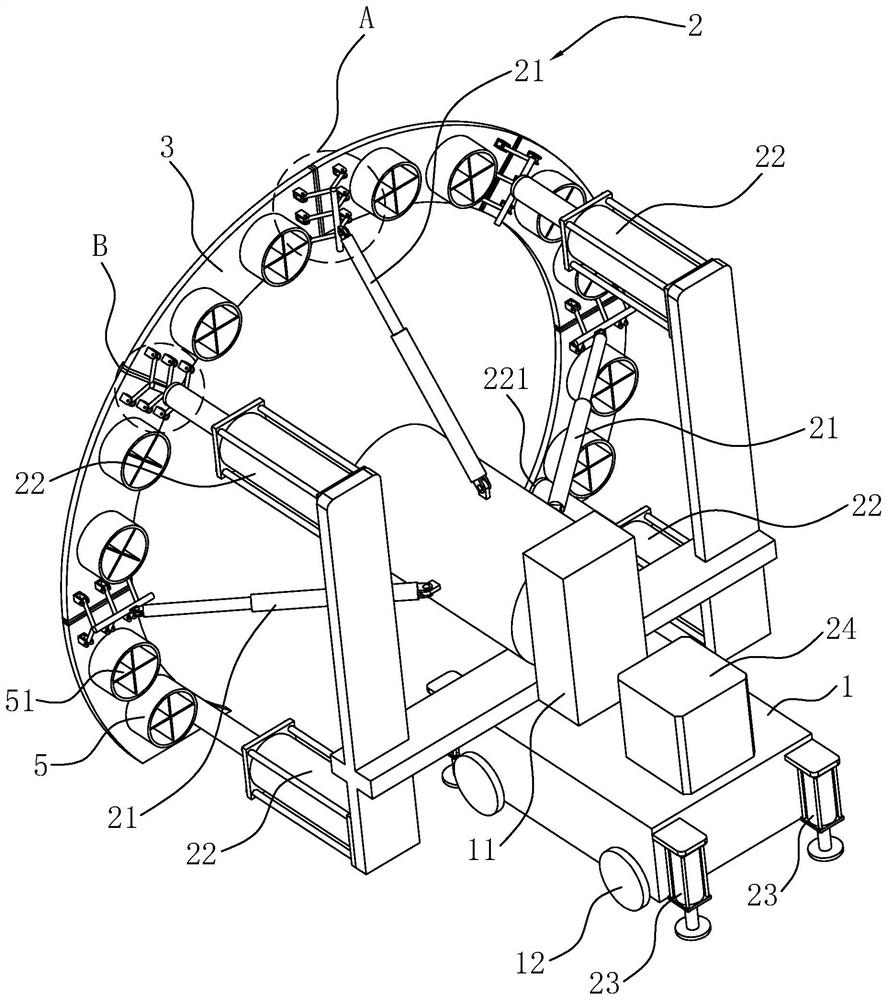

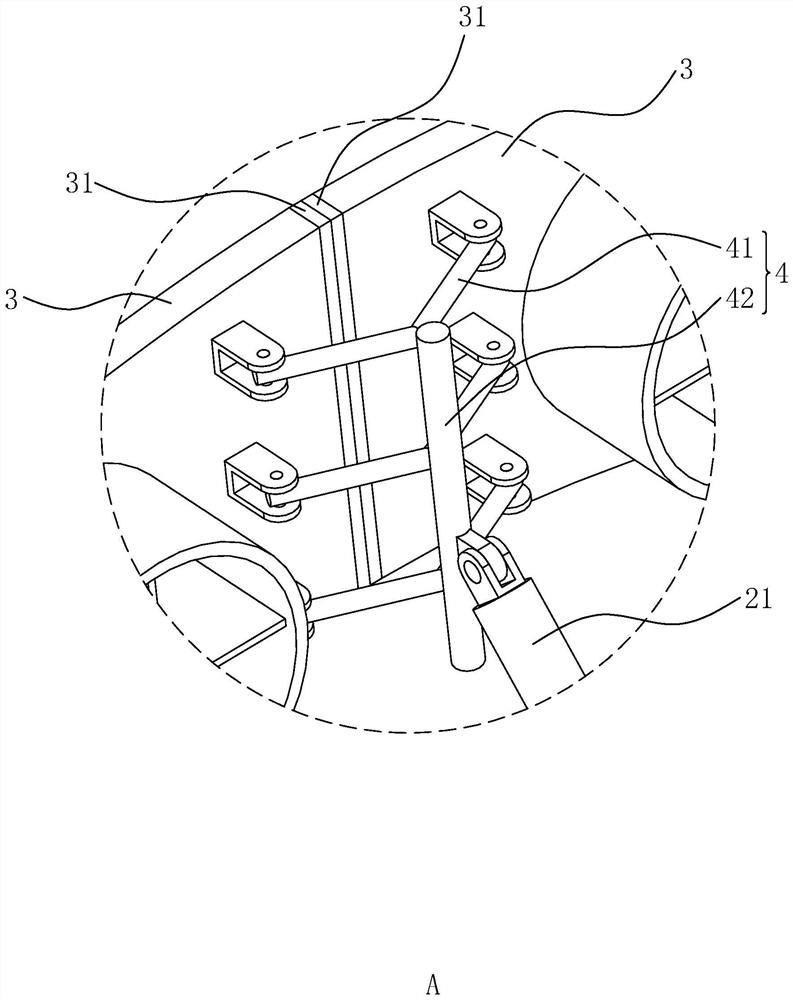

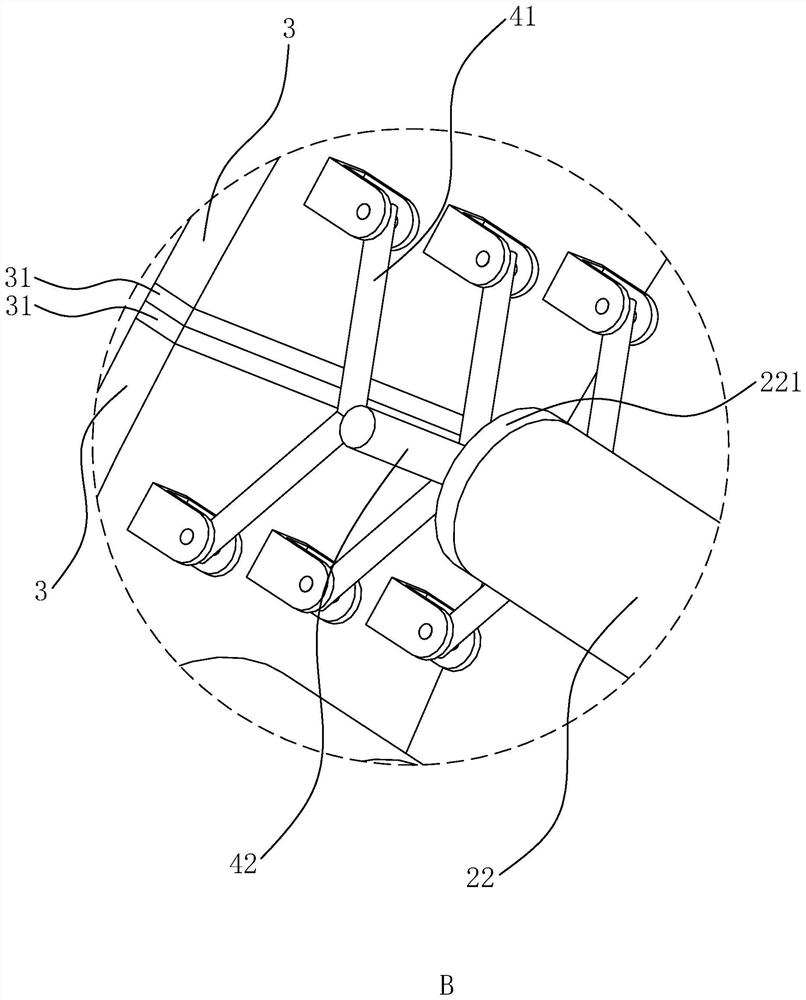

[0043] The following is attached Figure 1-4 The application is described in further detail.

[0044] The embodiment of the present application discloses a hydraulic jacking integral steel end formwork for the second lining of a highway tunnel. refer to figure 1, the hydraulic jacking integral steel end formwork for the secondary lining of the highway tunnel is placed on the ground and is used to block the end face of the secondary lining, including a pedestal 1, a hydraulic component 2 and an end formwork 3, the hydraulic component 2 is connected to the pedestal 1, and the end There are several templates 3, and the several end templates 3 are all connected to the hydraulic assembly 2, and the hydraulic assembly 2 is used to expand or fold the several end templates 3. When in use, the pedestal 1 is transported to the set position, and then several end formworks 3 are unfolded through the hydraulic assembly 2. After the secondary lining is completed, the several end formworks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com