Circulating conveying device for grenade fuse assembling machine

A technology for cyclic conveying and assembly machines, which is applied in the direction of conveyor objects, ammunition, transportation and packaging, etc., which can solve problems such as prone to inclination, affecting assembly, and high labor intensity, so as to avoid installation inclination, reduce floor space, The effect of reducing production input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. The following embodiments are used to illustrate the present invention , but not to limit the scope of the present invention.

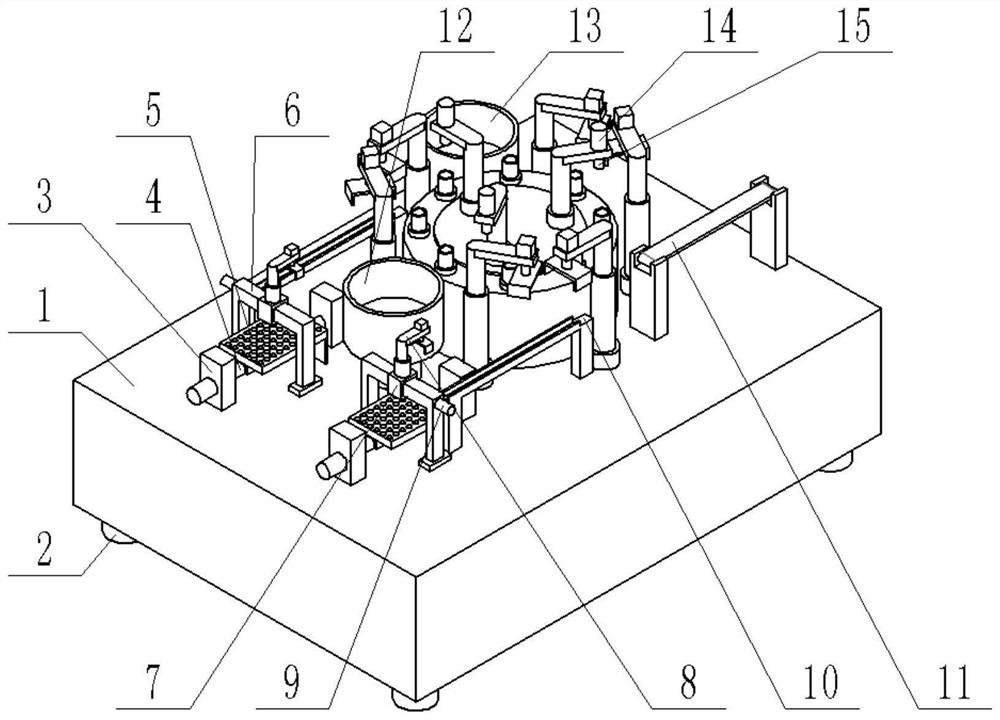

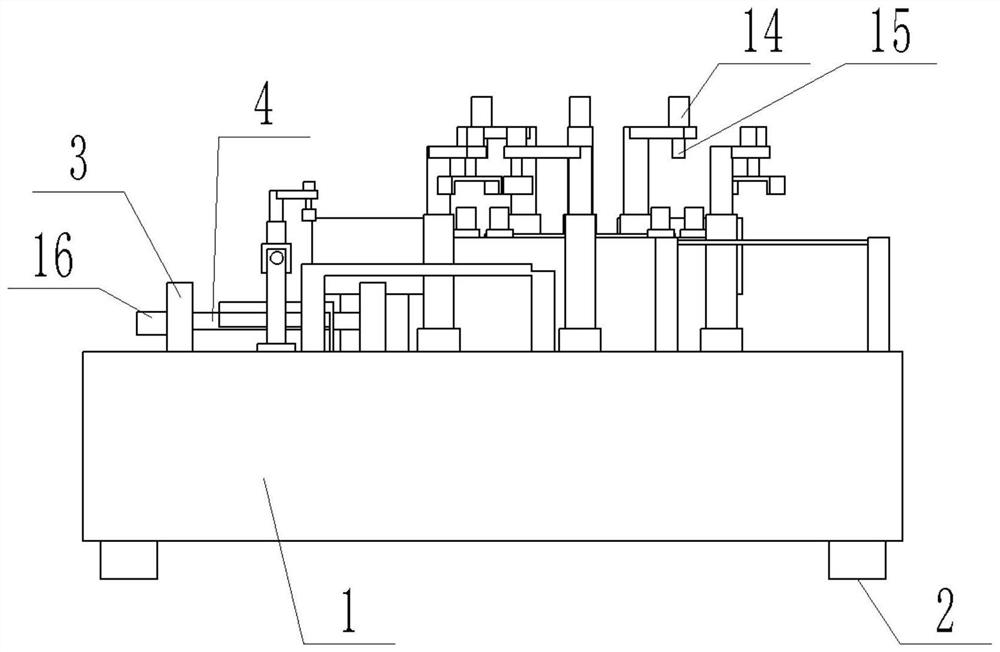

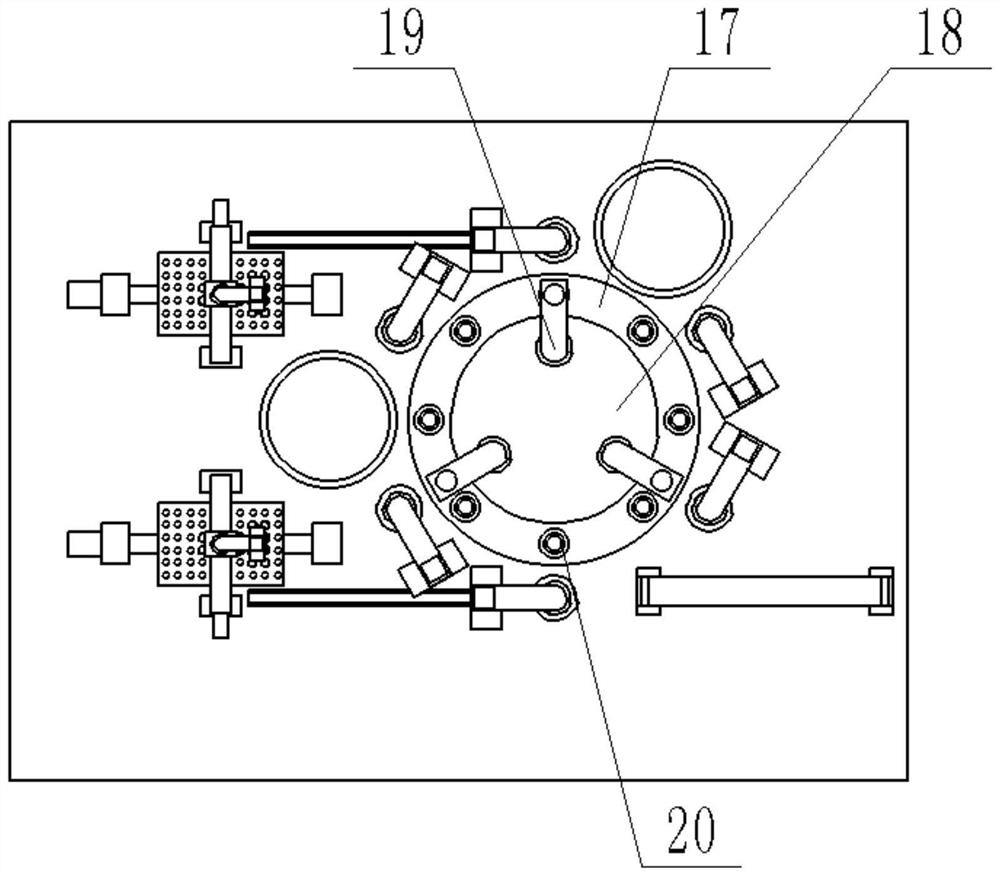

[0029] Such as Figure 1 to Figure 6 As shown, a circular conveying device for a hand grenade fuze assembly machine includes an equipment platform 1 and a supporting round table 18, the supporting round table 18 is fixedly installed on the equipment platform 1, a rotating disc 17 is arranged on the outside of the equipment platform 1, and the outer circumference of the rotating disc 17 is installed There are six assembly mechanical arms 34, and three downward correction frames 19 are evenly distributed on the support round table 18. The bottom of the assembly m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com