Ultra-precision cutting tool state parameter calculation method and system and application

A technology of state parameters and cutting processing, applied in the field of cutting processing, can solve problems such as inability to flexibly use multiple processing modes, lack of intuition, and too abstract derivation process, to achieve accuracy guarantee, clear geometric relationship, and strong applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

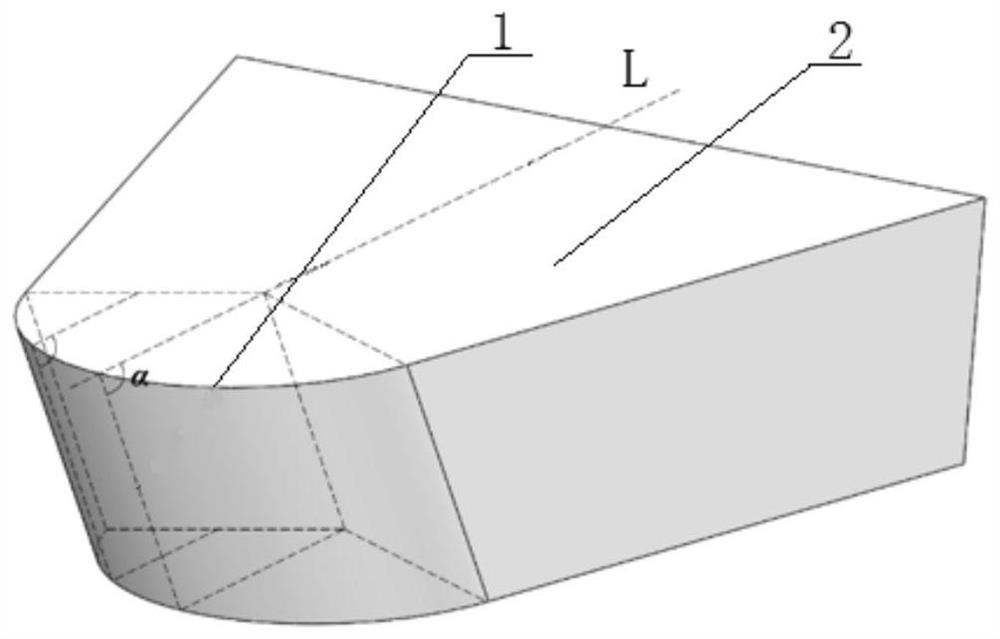

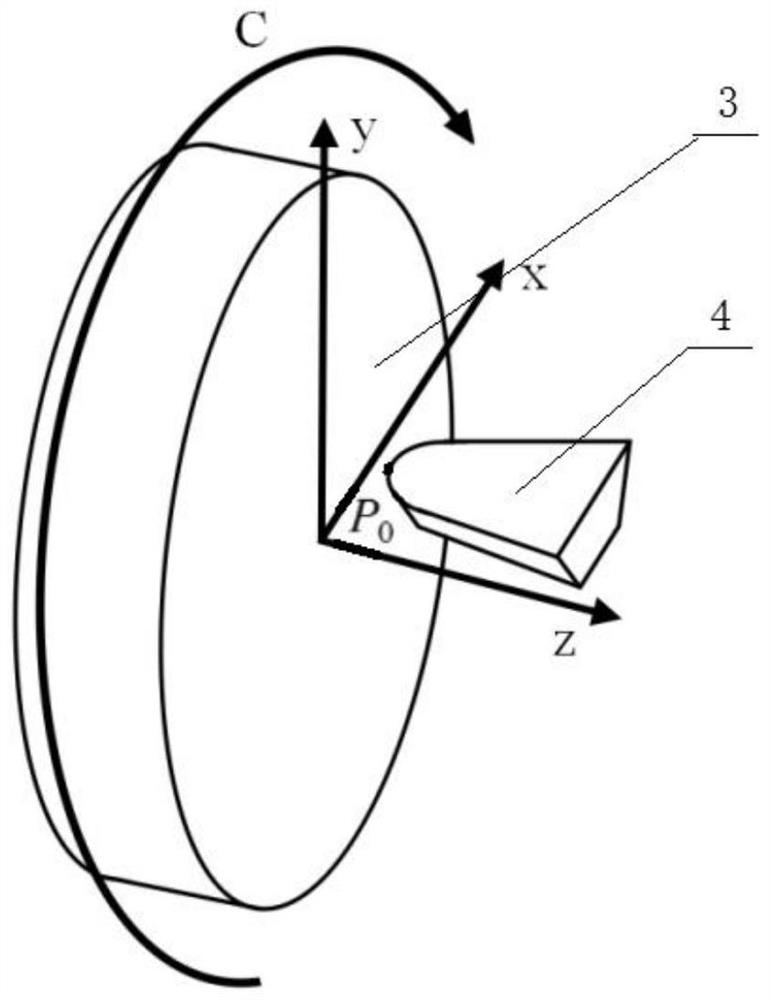

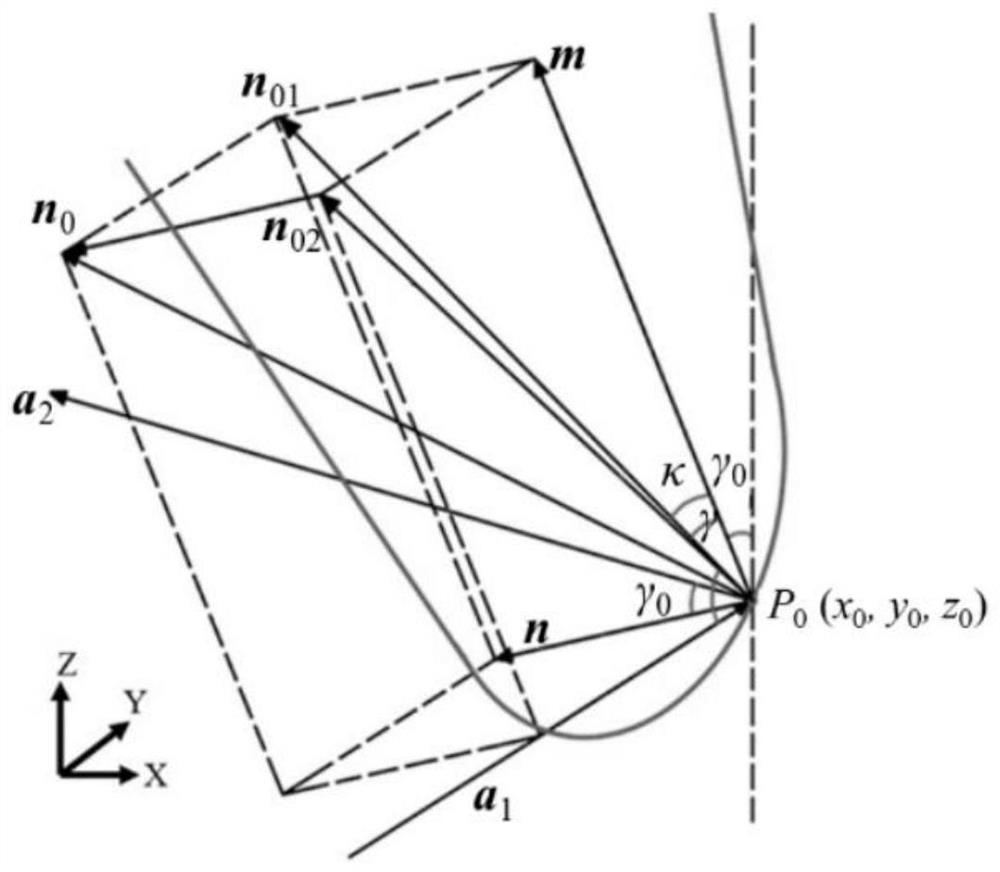

[0075] This embodiment of the invention provides a method for calculating the state parameters of ultra-precision cutting tools, which is used for example. Figure 1 The attitude field analysis of the inclined cylindrical diamond tool 4 shown in. such as Figure 2 As shown, in the machining process, the machined surface 3 rotates in the C direction around the main axis of rotation, and the cutter feeds along the X axis and the Z axis.

[0076] It should be noted that before cutting, in order to prevent the cutter 4 from breaking, it is necessary to adjust the angle of the cutter 4 in advance, and adjust the cutter 4 to the initial posture, which will always be maintained during cutting. If the central axis of the rake face 2 of the cutter 4 before adjustment is L, and L is parallel to the Z axis, then the initial rake angle γ. 0 Is the angle between the rake face 2 and L of the adjusted tool 4 in the initial state, that is, the angle between the central axis of the rake face of the ...

Embodiment 2

[0101] The invention provides a method for calculating the state parameters of cutting tools in ultra-precision cutting. The processing method of rotary cutting is as follows Figure 4 、 5 As shown, in the actual machining process, the cutter is fixed, the machined surface 6 rotates around the center of rotation, and at the same time, it is linked in the Y-axis and Z-axis directions. The cutting trajectory of the cutter on the machined surface 6 is projected as shown in Figure 6. Figure 5 On the cylindrical structure 5 shown, it is distributed in a thread shape along the circumferential direction. In the analysis process, it can be seen that the tool moves in the cylindrical structure 5, and its rotation center is located in the cylindrical structure 5, and its rotation direction can be seen as Figure 4 Move in direction D as shown. When the cutter moves counterclockwise along the thread track, the initial rake angle γ is set when the cutter leans forward. 0 Take negative value.

...

Embodiment 3

[0125] The invention provides a method for calculating the state parameters of cutting tools in ultra-precision cutting. The grid line planing method is as follows Figure 7 、 8 As shown in the figure, in the actual machining process, the cutter is kept fixed, and the machined surface moves relative to the cutter for cutting. The moving mode of the machined surface 6 is as follows: the cutter cuts a curved track on the machined surface 6 along the Y-axis and Z-axis, then the machined surface 6 returns to its initial position, rotates in the E-direction around the central axis of rotation, fine-tunes the machining angle, and then moves along the Y-axis and Z-axis. The above steps are repeated until the machining is completed, and the cutting path of the cutter relative to the machined surface 6 is grid-line. Projecting the running track of the tool on the curved surface onto the cylindrical structure 5 to obtain the following results. Figure 8 In the analysis process, the tool can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com