Flat wire continuous wave winding structure, stator with same, motor and vehicle

A wave winding and winding technology, which is applied in flat wire continuous wave winding structures, stators, motors and vehicles, can solve the problems of increasing the additional loss of motors, difficulty in arranging wave windings, and high mold investment costs, so as to improve slot fill rate, The effect of increasing the available space and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

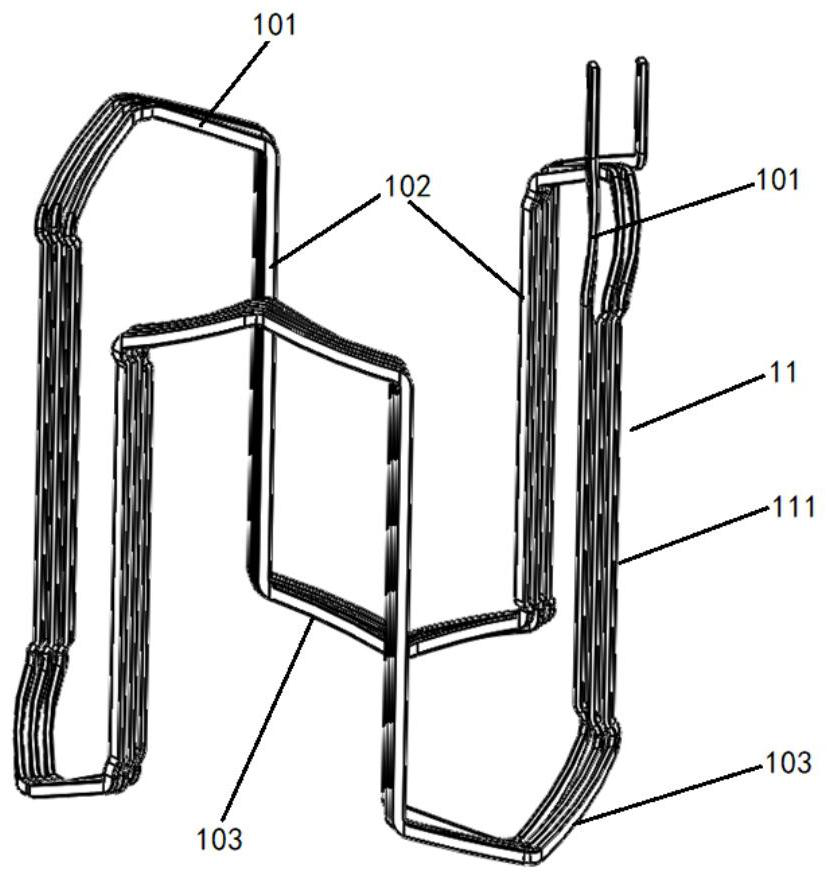

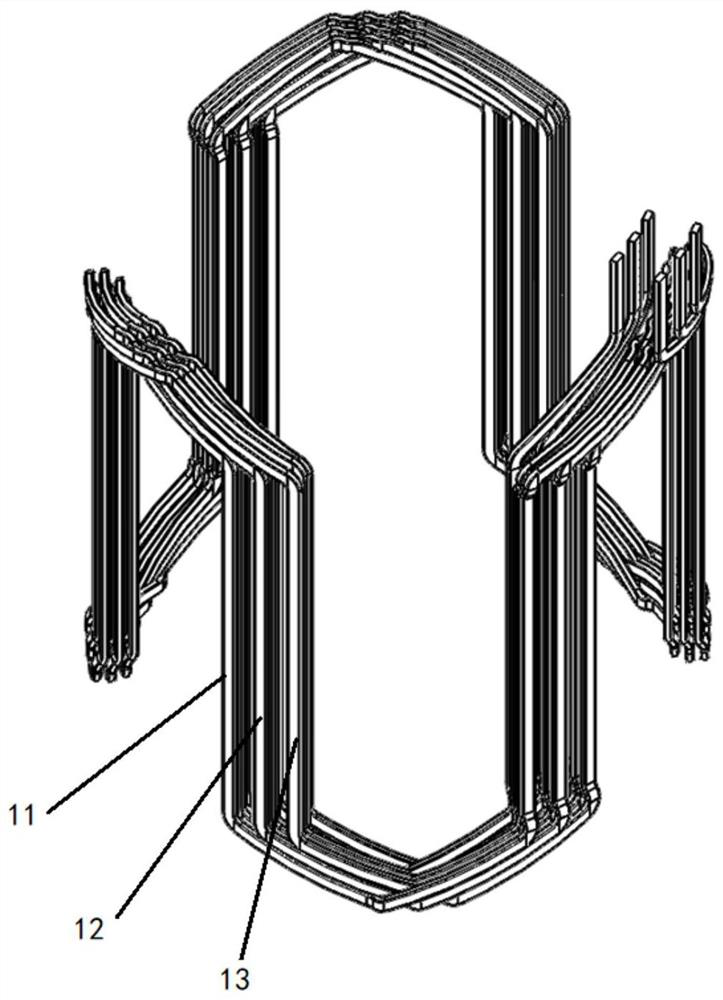

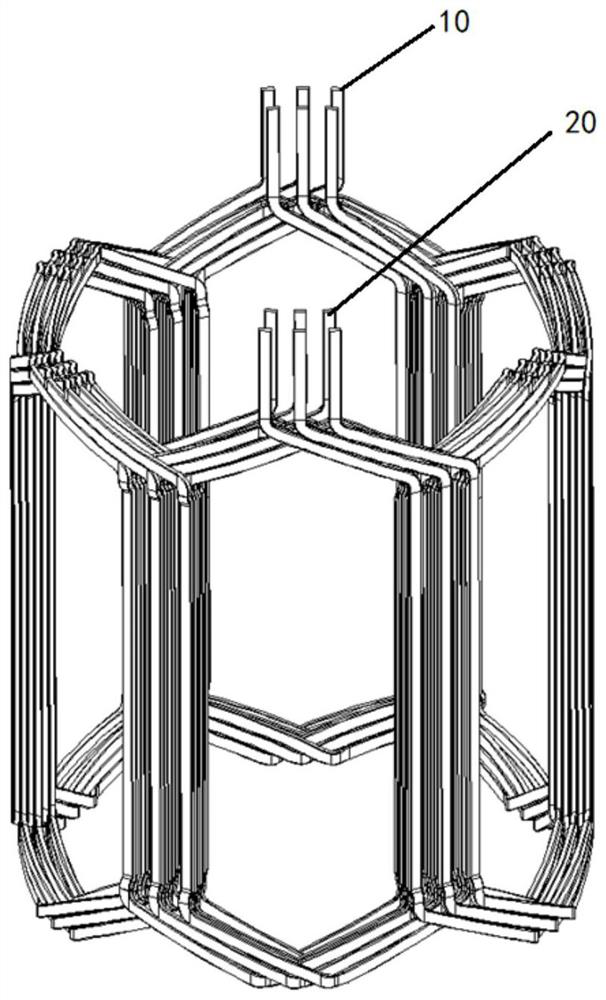

[0057] The flat wire continuous wave winding structure of the present invention includes a three-phase continuous wave winding, and each phase continuous wave winding includes an incoming wire end, an outgoing wire end and a continuous wave winding coil located between the incoming wire end and the outgoing wire end. It can be understood that the flat wire continuous wave winding structure in this embodiment may be in the form of U, V, W three-phase windings.

[0058] The continuous wave winding of each phase includes the first branch winding and the second branch winding in parallel, the number of stator slots of each phase branch winding is nm, the total number of stator slots is 3nm, n is the number of poles of the motor, m is the number of coils contained in each branch winding; the number of winding layers of the stator slot is 2M layers, and the span of the coils in each layer is 3m; the incoming and outgoing ends of each phase continuous wave winding are located at The ...

Embodiment 2

[0084] The flat wire continuous wave winding structure of the present invention includes a three-phase continuous wave winding, and each phase continuous wave winding includes an incoming wire end, an outgoing wire end and a continuous wave winding coil located between the incoming wire end and the outgoing wire end. It can be understood that the flat wire continuous wave winding structure in this embodiment may be in the form of U, V, W three-phase windings.

[0085] The continuous wave winding of each phase includes the first branch winding and the second branch winding in parallel, the number of stator slots of each phase branch winding is nm, the total number of stator slots is 3nm, n is the number of poles of the motor, m is the number of coils contained in each branch winding; the number of winding layers of the stator slot is 2M layers, and the span of the coils in each layer is 3m; the incoming and outgoing ends of each phase continuous wave winding are located at The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com