Stropharia rugoso-annulata fresh base material and preparation method and application thereof

A technology for the preparation of base mushroom and base material, which is applied in the fields of application, food science, food ingredients, etc., can solve the problems that the enzymatic hydrolysis process is not easy to control, affect the taste of the base material preparation, and the cost of separation equipment is high, and achieves sensory richness and pleasure, Increase the added value of products and the effect of enriching nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention provides the preparation method of base material in above-mentioned technical scheme, comprises following preparation steps:

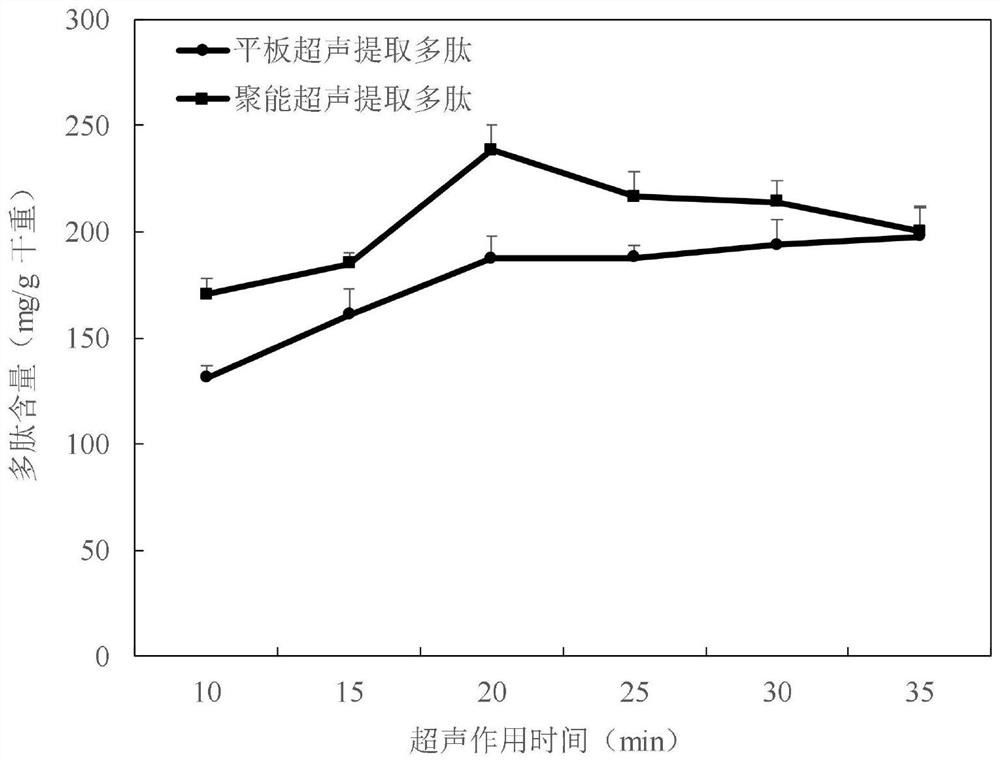

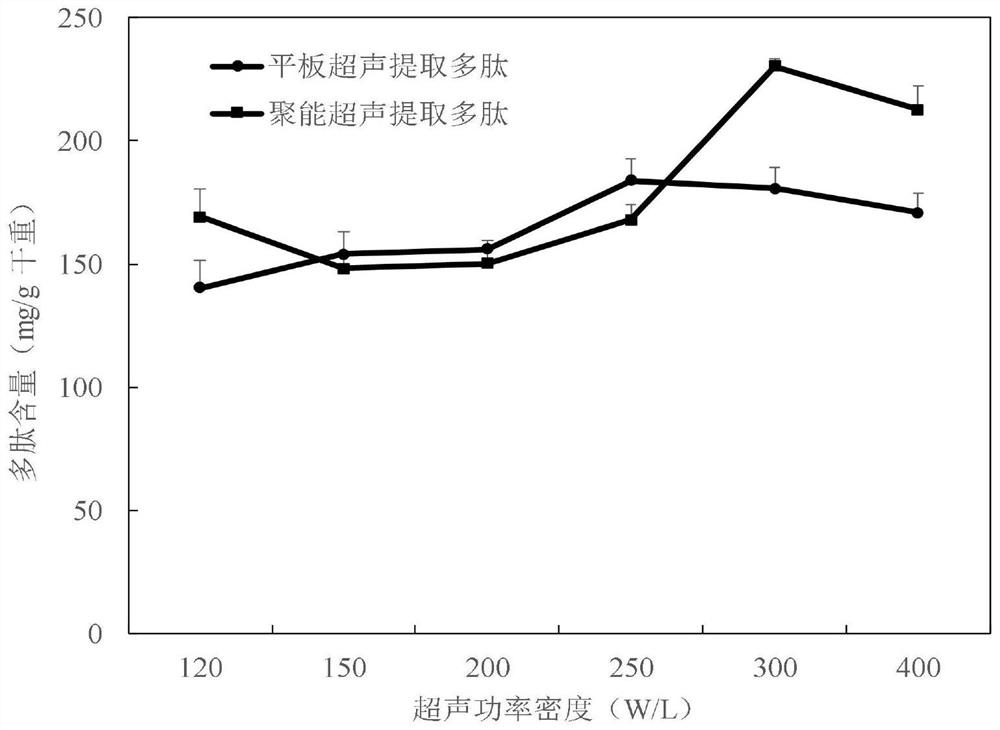

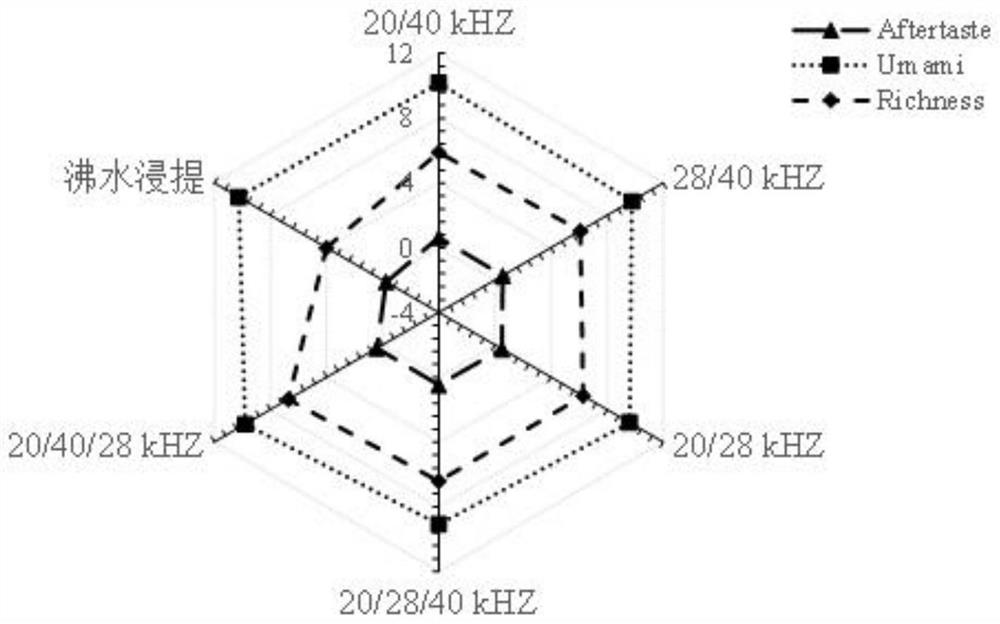

[0032] Ultrasonic extraction of stropharia to obtain the fresh base material of the stropharia;

[0033] The power density of the ultrasonic extraction is 110-400W / L.

[0034] The present invention preferably carries out ultrasonic extraction to the dry powder of Stropharia stropharia, and the preparation method of the dry powder of Stropharia stropharia preferably comprises drying and pulverizing the dry stropharia to obtain the dry powder of Stropharia stropharia, and the dry powder of Stropharia stropharia Preferably it is a fruiting body of Stropharia grandis. The present invention preferably uses hot air drying for drying, the temperature of the hot air drying is preferably 45-65°C, more preferably 55°C; the ventilation rate is preferably 3200-3800m 3 / h, more preferably 3500m 3 / h; the heating rate is preferably 8-...

Embodiment 1

[0051] Put the fruiting bodies of Stropharia grandis at a temperature of 50°C and a ventilation rate of 3500m 3 / h under the condition of drying for 12h to obtain the dried fruiting body of Stropharia, and the heating rate was 10℃ / min. Stropharia stropharia is crushed to a particle size of 60-100 mesh to obtain dry fruiting body powder of stropharia. Mix 50g of dry powder with 1L of water and extract it with a flat-panel ultrasonic equipment. The preparation conditions are single-frequency and high-power density. The specific ultrasonic power density is 300W / L, the ultrasonic frequency is 20kHz, and the pulse duration of ultrasonic frequency is 5s. Single-frequency ultrasonic The interval time after the action is 5s, and the extraction time of the ultrasonic action is 10min. Centrifuge at 8000rpm for 15min, collect the supernatant, freeze-dry at -70°C for 48h, and obtain the fresh base material of Stropharia grandis.

Embodiment 2

[0053] The technical solution in Example 1 was used to extract the fresh base material of Stropharia stropharia, the difference being that the ultrasonic extraction time was 15 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com