Online measurement method and system for coil diameter of hot rolled steel coil

A hot-rolled steel coil and measurement system technology, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of the influence of coil diameter calculation accuracy, achieve the effect of simple device, reduce cumulative error, and avoid calculation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

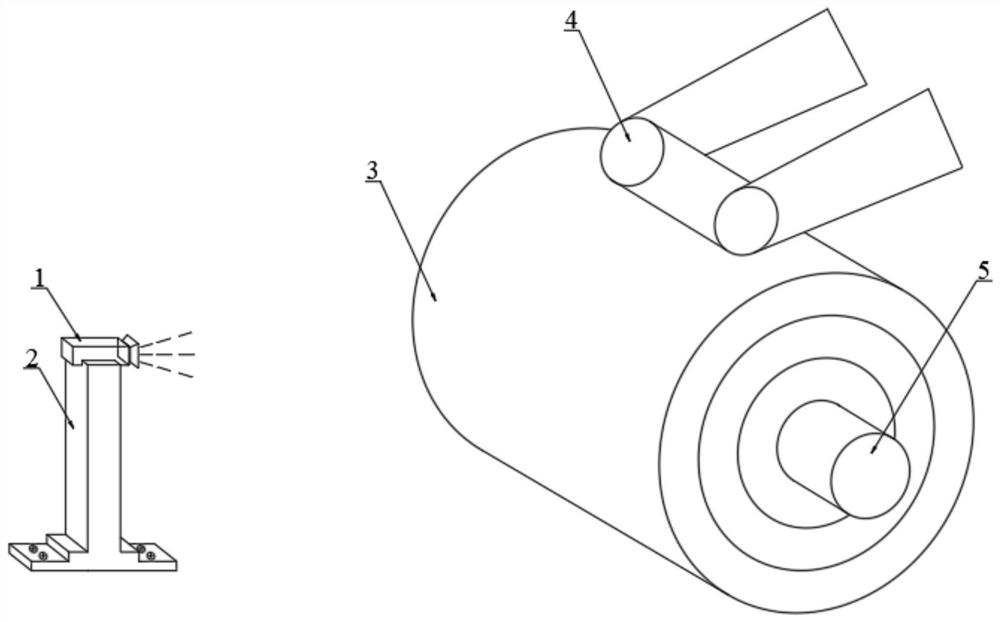

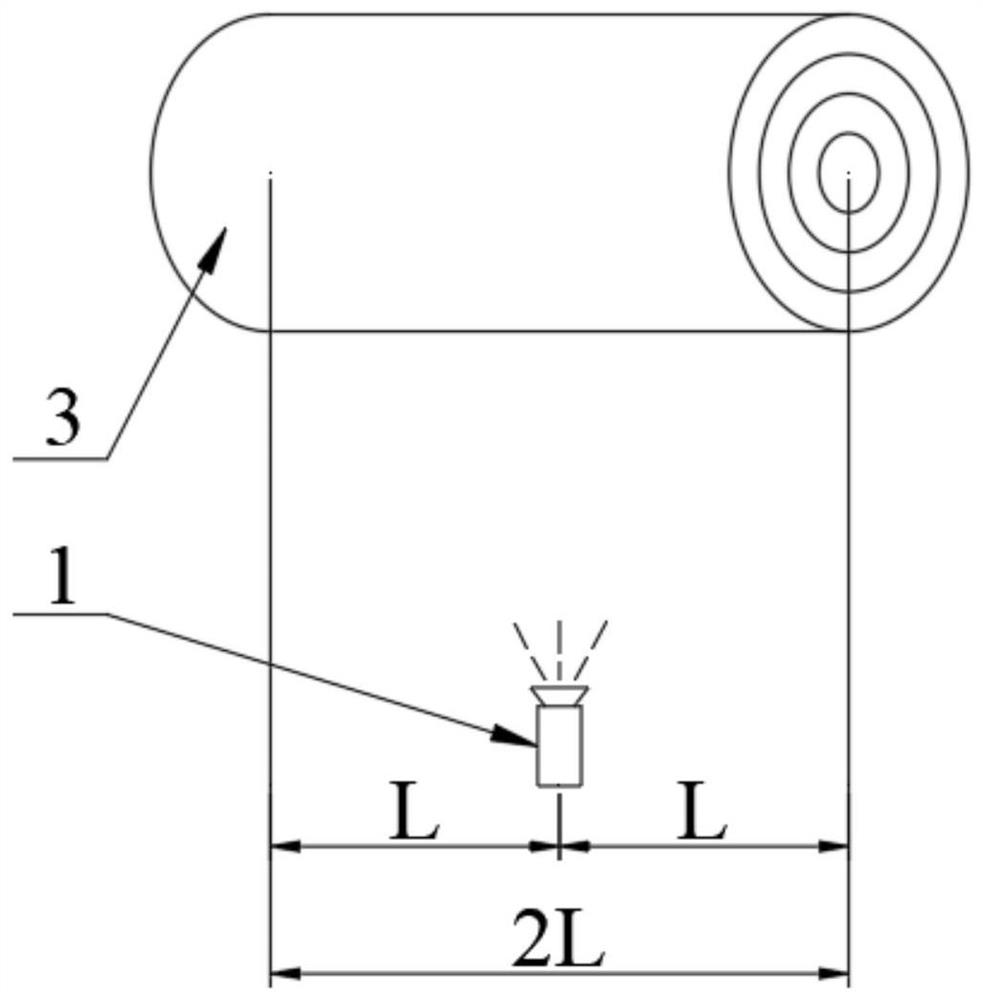

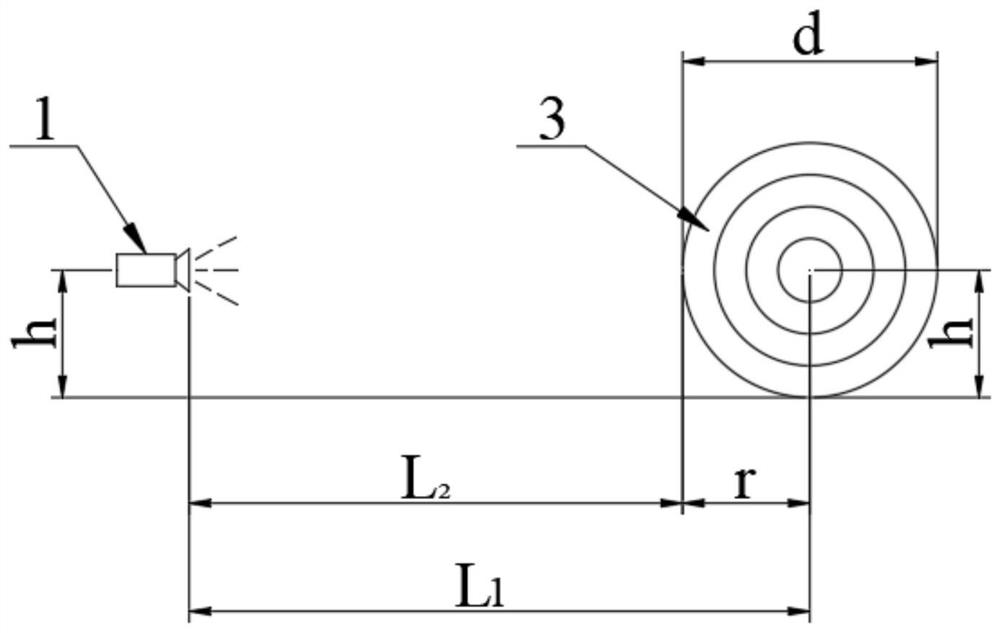

[0043] like Figure 1-3 As shown, the present invention provides an on-line measurement system for hot-rolled steel coil diameter, comprising: an ultrasonic distance measuring sensor 1, a support frame 2 and a host computer, the ultrasonic distance measuring sensor is installed on the support frame, and the support frame is fixed on the ground Above; in the radial direction of the steel coil of the coiler, the ultrasonic distance measuring sensor is set at intervals with the steel coil, and the ultrasonic distance measuring sensor is set in the middle of the steel coil bandwidth in the direction of the central axis; the ultrasonic distance measuring sensor is kept in the working process fixed position;

[0044] The ultrasonic ranging sensor is set parallel to the ground and installed at the same height as the central axis of the reel. By fixing the support frame, the distance between the ultrasonic ranging sensor and the center of the reel is fixed, and the distance between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com