Forming die and forming method for blade with multi-powder structure in circumferential direction

A technology of forming molds and forming methods, which is applied in other manufacturing equipment/tools, turbines, engine components, etc., can solve the problems of inability to achieve wear resistance and impact resistance at the same time, insufficient performance of blades, and inability to achieve forming requirements, etc., to achieve Simple structure, easy operation, uniform molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

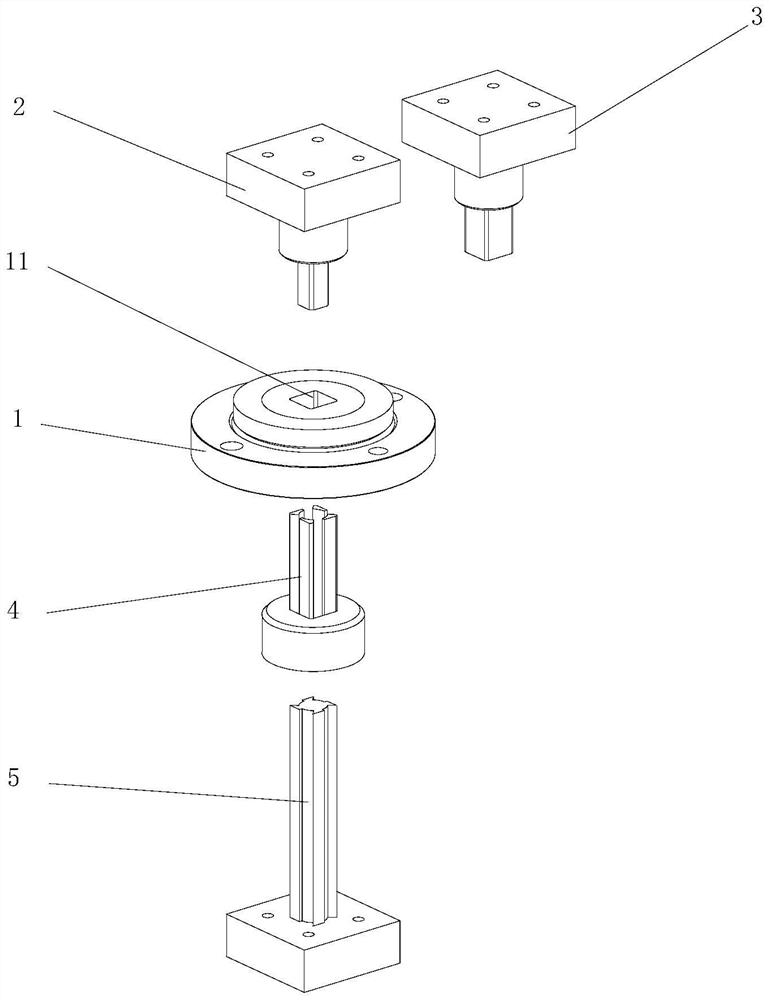

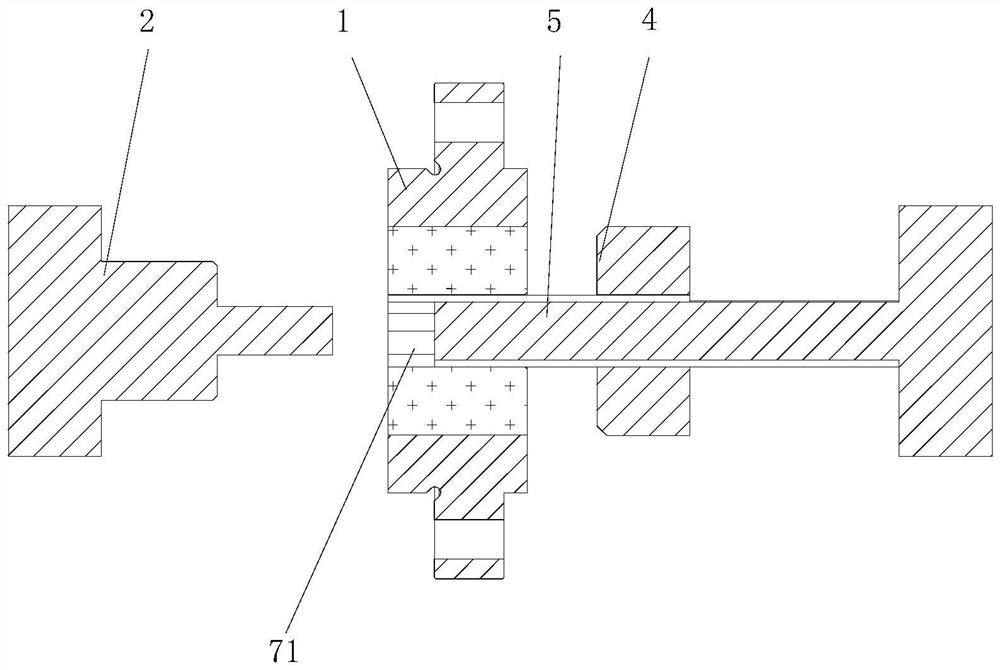

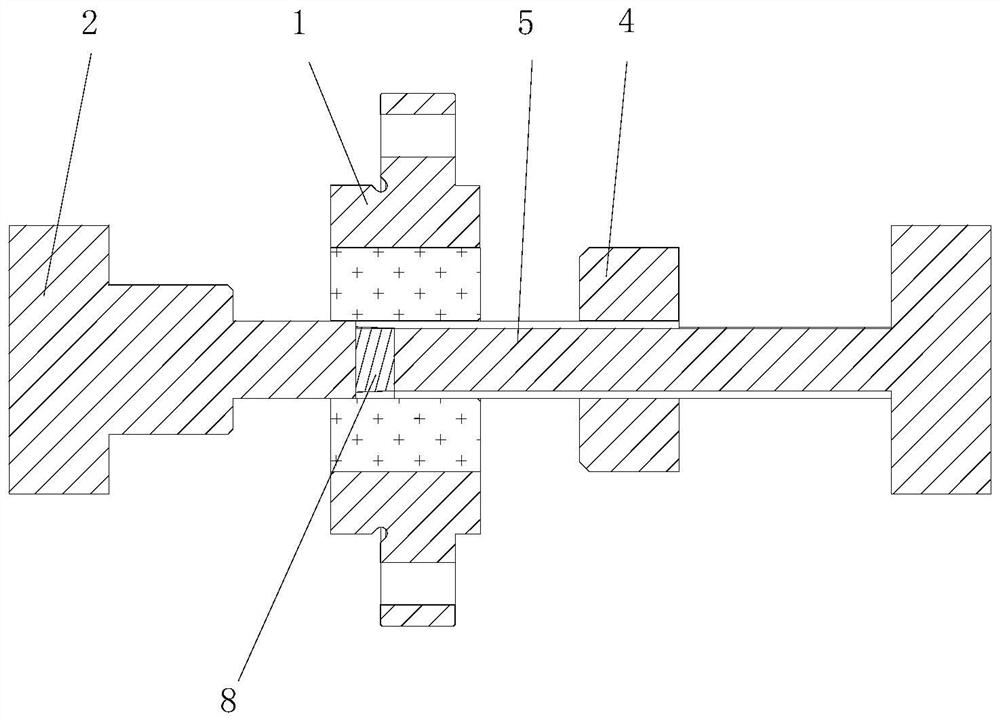

[0038] figure 1 Shown is the first embodiment of the molding die with multi-powder structure blades in the circumferential direction of the present invention, which includes a die body 1, a first upper punch 2, a second upper punch Head 3, outer lower punch 4, inner lower punch 5 and installation mold base, mold body 1 is installed on the installation mold base and can move up and down, mold body 1 is provided with a mold cavity 11, the first upper punch 2 , the second upper punch 3, the outer lower punch 4, and the inner lower punch 5 can move up and down to enter or stay away from the mold cavity 11, the first upper punch 2, the outer lower punch 4, the inner lower punch 5 and Die cavity 11 cooperates to realize the molding that circumferentially has multi-powder structure blade first circumferential matrix 61 and central matrix 63...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap