Preparation method for fine grinding wheel

A fine grinding grinding wheel and abrasive technology, applied in the field of grinding wheels, can solve the problems of grinding wheel wear resistance, self-sharpening, cost, and grinding accuracy can not be effectively taken into account, to ensure sintering and adhesive bonding strength, take into account cutting performance, enhance adhesion Focus on the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

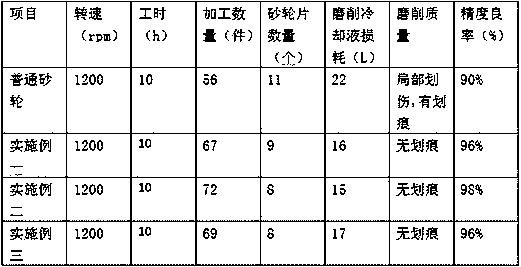

Embodiment 1

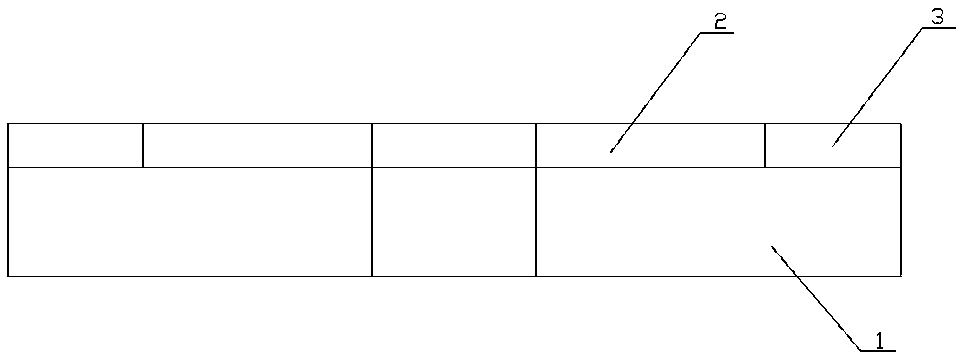

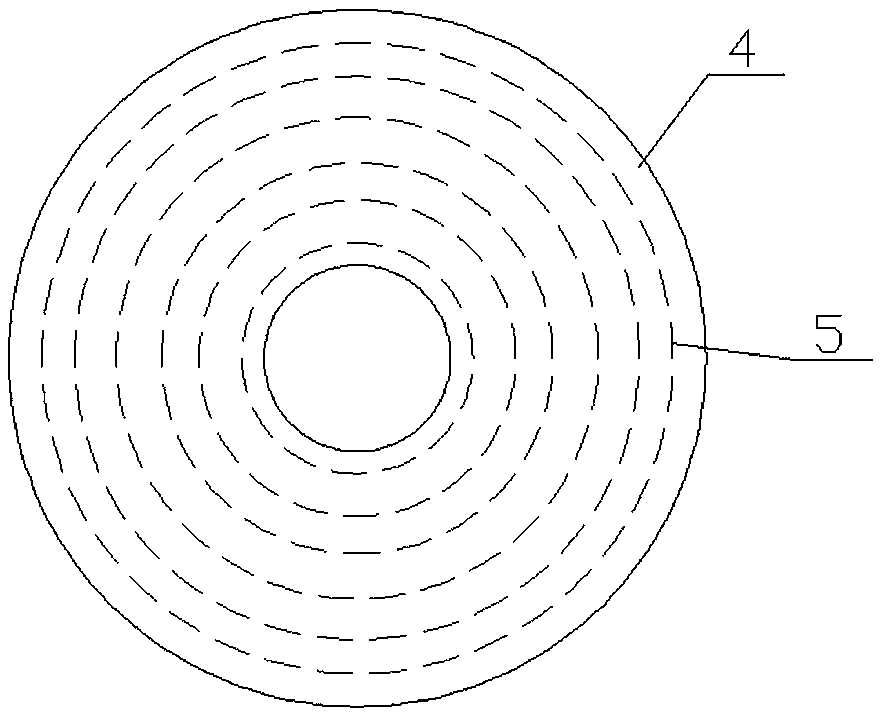

[0024] A fine grinding wheel,

[0025] The base plate is composed of 22Kg of FKF composite mineral fiber, 8Kg of ceramic fiber, 15Kg of aramid fiber, 5Kg of high abrasion-resistant brass wire, 20Kg of sepiolite fiber and 15Kg of glass fiber;

[0026] The outer ring abrasive disc comprises in parts by mass: boron nitride abrasive 30 with particle size F200, corundum abrasive 10 with particle size F200, modified graphene 5, manganese zinc ferrite 3, nano silicon dioxide 5, aluminum oxide 2. Sodium carbonate 2, aluminum-magnesium alloy powder 3, copper powder 3, borax 3;

[0027] The inner ring abrasive disc comprises in parts by mass: silicon carbide abrasive 35 with particle size F170, hollow glass microspheres 8, nickel powder 3, gypsum 6, copper oxide 3, zinc oxide 3, zircon sand 3, polyester resin 10. Brominated epoxy resin phenolic curing agent 2.

[0028] The selected mass parts of viscose include: 80 parts of polyethylene, 10 parts of polyimide resin powder, 10 parts of...

Embodiment 2

[0037] A fine grinding wheel,

[0038] The base plate is composed of 22Kg of FKF composite mineral fiber, 8Kg of ceramic fiber, 15Kg of aramid fiber, 5Kg of high abrasion-resistant brass wire, 20Kg of sepiolite fiber and 15Kg of glass fiber;

[0039] The outer ring abrasive disc comprises in parts by mass: boron nitride abrasive 35 with particle size F210, corundum abrasive 12 with particle size F200, modified graphene 6, manganese zinc ferrite 3, nano silicon dioxide 5.5, aluminum oxide 3. Sodium carbonate 3, aluminum-magnesium alloy powder 4, copper powder 4, borax 4;

[0040] The inner ring abrasive disc comprises in parts by mass: silicon carbide abrasive 38 with particle size F170, hollow glass microspheres 10, nickel powder 4, gypsum 6.5, copper oxide 3.5, zinc oxide 3.8, zircon sand 3.2, polyester resin 12. Brominated epoxy resin phenolic curing agent 2.5.

[0041] The selected mass parts of viscose include: polyethylene 85 parts, polyimide resin powder 12 parts, isop...

Embodiment 3

[0050] A fine grinding wheel,

[0051] The base plate is composed of 22Kg of FKF composite mineral fiber, 8Kg of ceramic fiber, 15Kg of aramid fiber, 5Kg of high abrasion-resistant brass wire, 20Kg of sepiolite fiber and 15Kg of glass fiber;

[0052] The outer ring abrasive disc comprises in parts by mass: boron nitride abrasive 40 with particle size F240, corundum abrasive 15 with particle size F240, modified graphene 8, manganese zinc ferrite 4, nano silicon dioxide 6, aluminum oxide 4. Sodium carbonate 4, aluminum-magnesium alloy powder 6, copper powder 5, borax 4;

[0053] The inner ring abrasive disc comprises in parts by mass: silicon carbide abrasive 40 with particle size F190, hollow glass microspheres 12, nickel powder 5, gypsum 8, copper oxide 5, zinc oxide 4, zircon sand 4, polyester resin 15. Brominated epoxy resin phenolic curing agent 3.

[0054] The selected mass parts of viscose include: 90 parts of polyethylene, 20 parts of polyimide resin powder, 15 parts o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap