Assembly tool and assembly method for rudder shaft type component for ceramic-based composite aircraft

An assembly tooling and ceramic-based technology, applied in the direction of connecting components, workpiece clamping devices, manufacturing tools, etc., can solve the problem that it is difficult to meet the performance index requirements of aircraft thermal protection products, the facets of the composite skeleton and the axis of the rudder shaft are not coplanar, High precision requirements for the preparation of individual parts, etc., to achieve the effect of taking into account the realization and machinability of assembly operations, taking into account the machinability of the shaft shape, and reducing the risk of processing faults

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

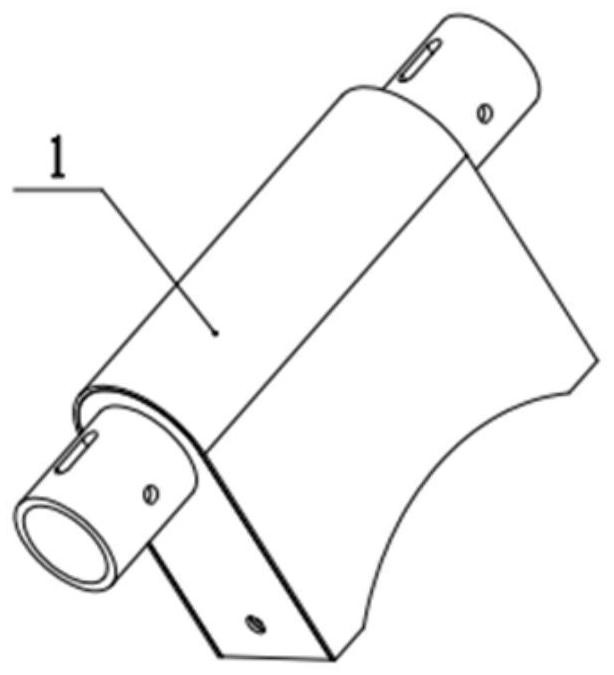

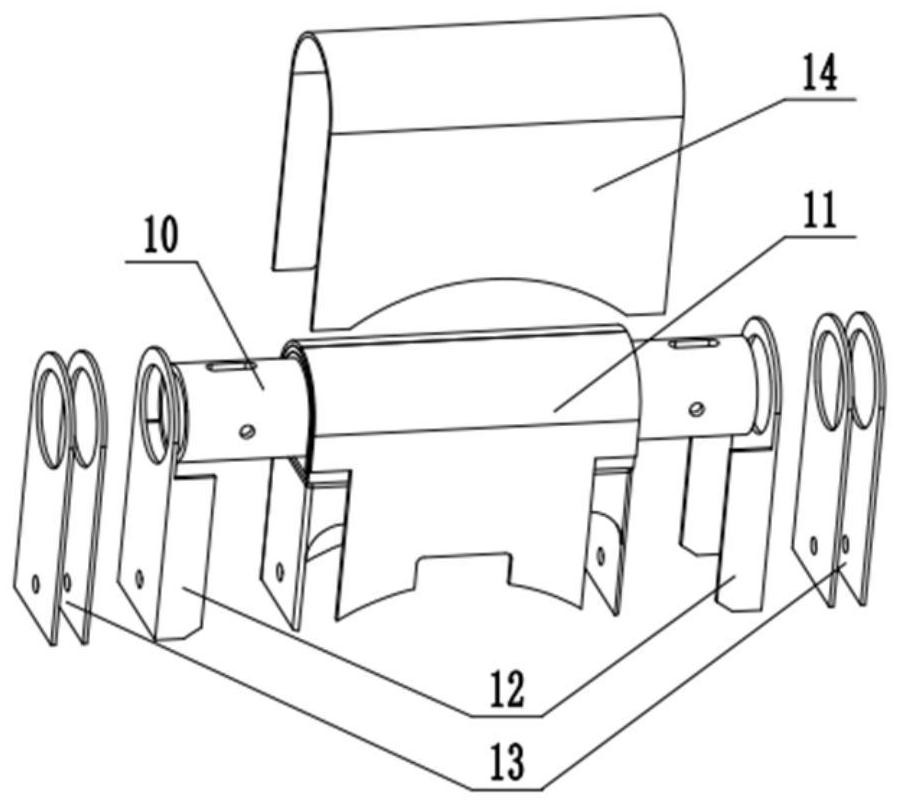

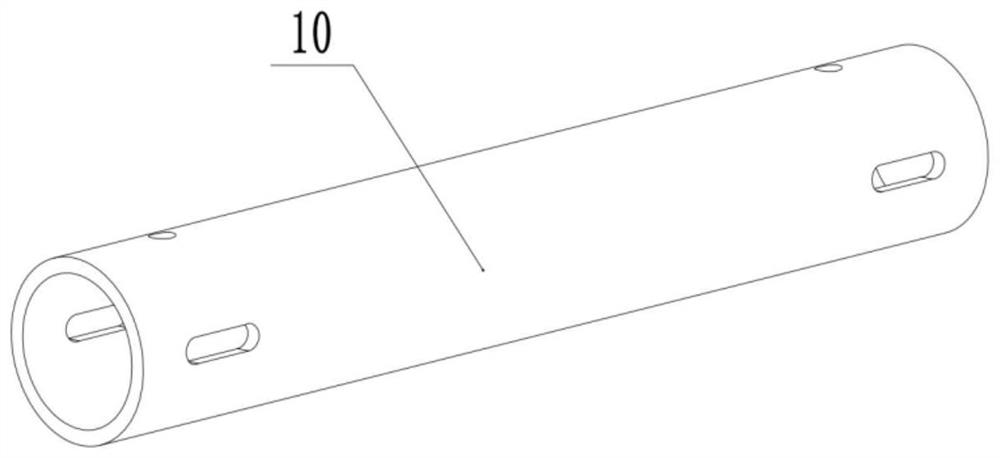

[0090] like Figure 1 to Figure 5 It is the structure of the rudder shaft member 1 to be assembled in the embodiment of the present invention. The rudder shaft member 1 is mainly composed of a rudder shaft 10 , a frame assembly 11 , a side beam assembly 12 , an ear piece assembly 13 , and a skin 14 . The side beam assembly 12 and the lug assembly 13 are respectively installed on both ends of the rudder shaft 10 . The frame assembly 11 is composed of a shaft sleeve 110, a connecting beam 111, a shaft backing plate 112, a front connecting arc plate and a rear connecting arc plate 113; the side beam assembly 12 is composed of an upper side beam 120 and a lower side beam 121; the ear piece assembly 13 is composed of Two upper ear pieces 130 and two lower ear pieces 131 are formed.

[0091] like Figure 6-Figure 17 As shown, a rudder shaft componen...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap