Industrial automatic cutting device capable of conveniently adjusting cutting width

An industrial automation and cutting device technology, which is applied in the direction of manufacturing tools, wood processing equipment, special forming/shaping machines, etc., can solve the problems affecting the use of boards, cutting boards into different widths, etc., and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

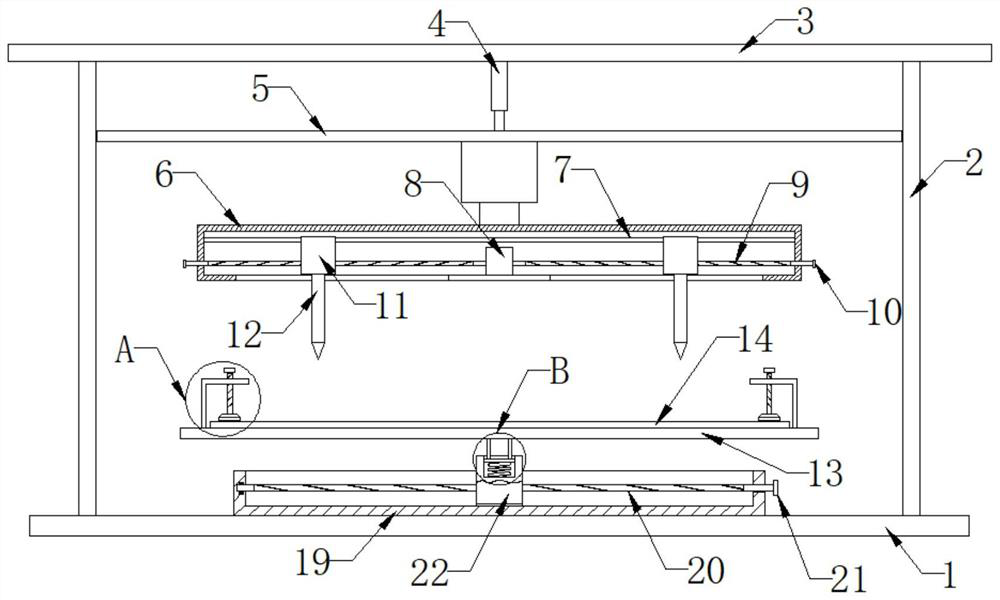

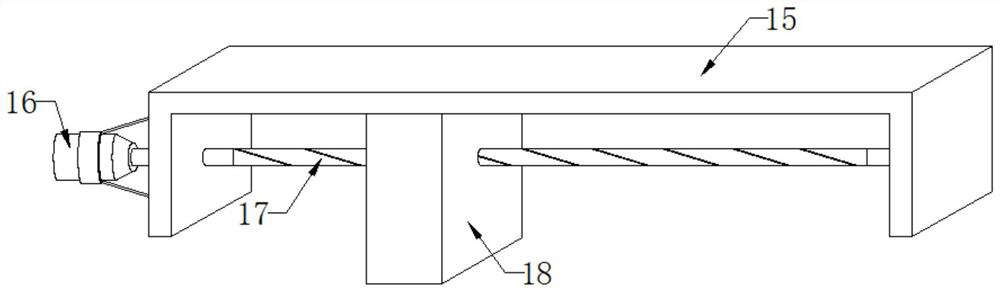

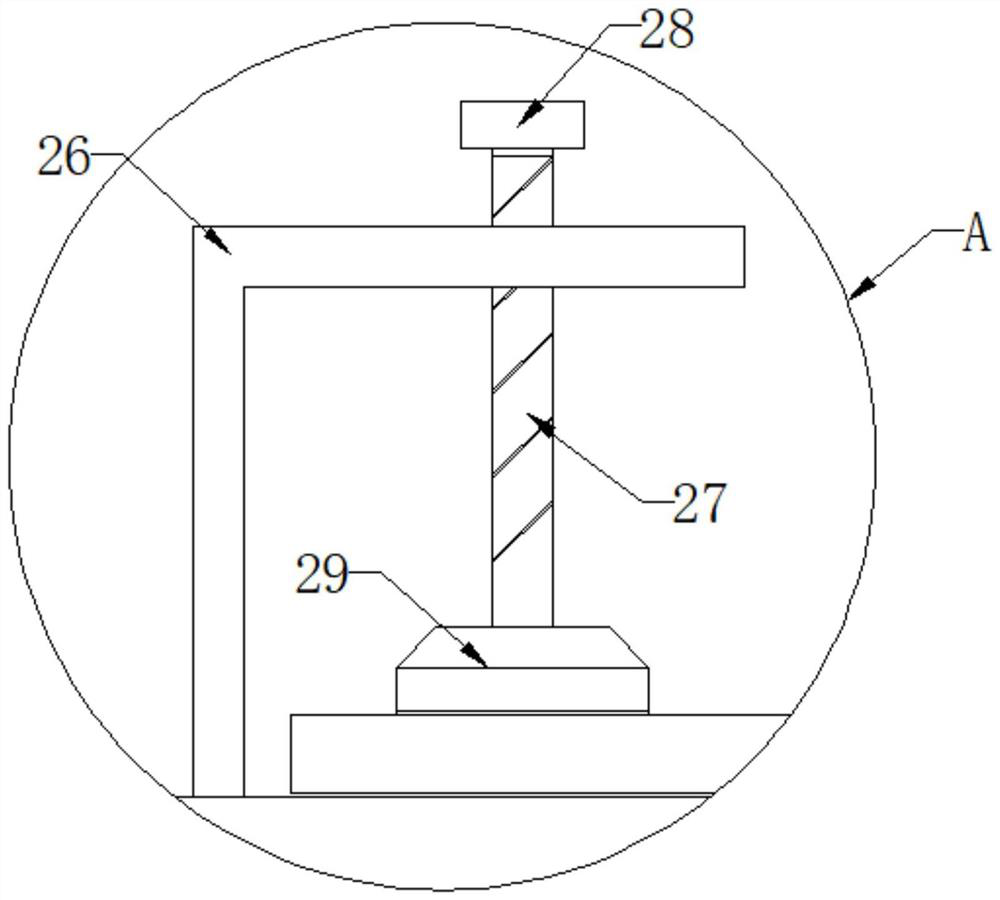

[0020] see Figure 1-4 , the present invention provides a technical solution: an industrial automatic cutting device that is convenient for adjusting the cutting width, including a bottom plate 1, two ends of the upper side wall of the bottom plate 1 are longitudinally fixed with symmetrical support plates 2, and the upper ends of the two support plates 2 The common horizontal plate 3 is fixedly arranged, the lower end of the horizontal plate 3 is longitudinally provided with a hydraulic rod 4, the upper end of the hydraulic rod 4 is fixedly connected with the lower side wall of the horizontal plate 3, and the lower end of the hydraulic rod 4 is fixedly provided with a slide plate 5, the slide plate 5 Both the left side wall and the right side wall are slidingly connected with the side walls of the two support plates 2, and the lower end of the slide plate 5 is fixedly provided with an adjustment frame 6 through a moving mechanism, and the inside of the adjustment frame 6 is ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com