3D printing equipment adopting artificial intelligence control system

A control system and 3D printing technology, applied in the field of 3D printing, can solve the problems of low efficiency of manual peeling, easily damaged products, poor peeling quality, etc., and achieve the effect of high peeling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

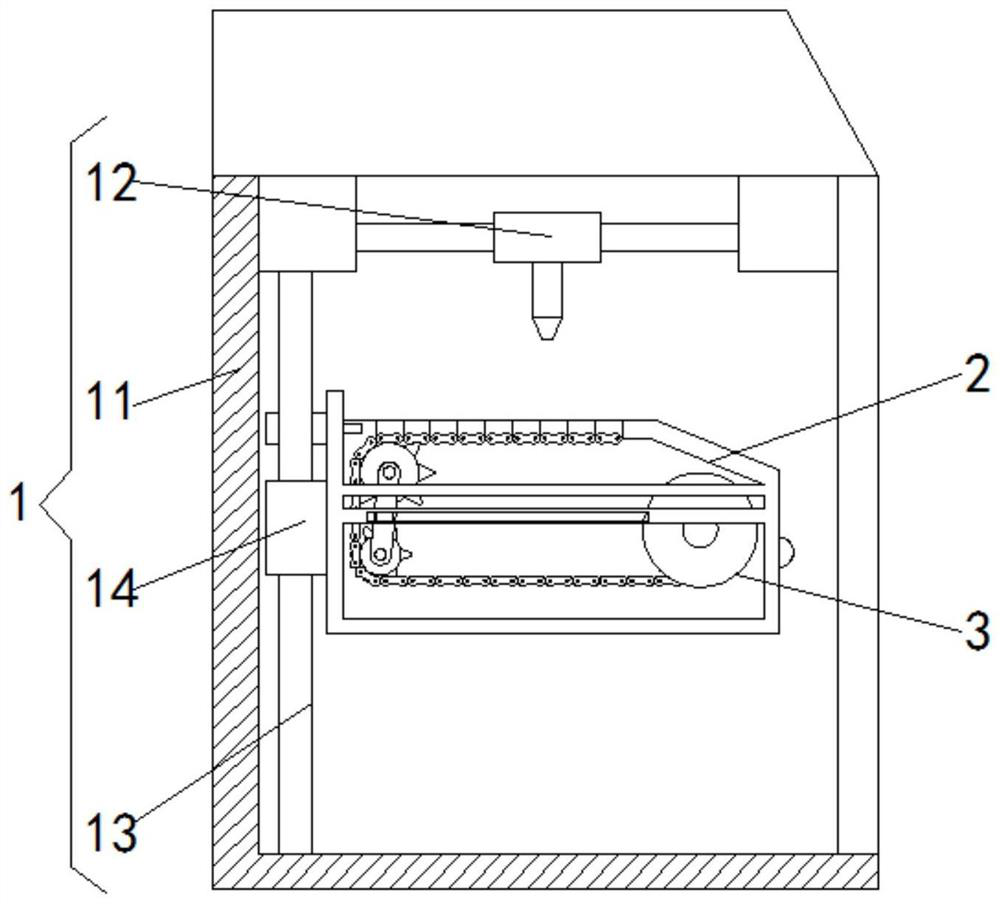

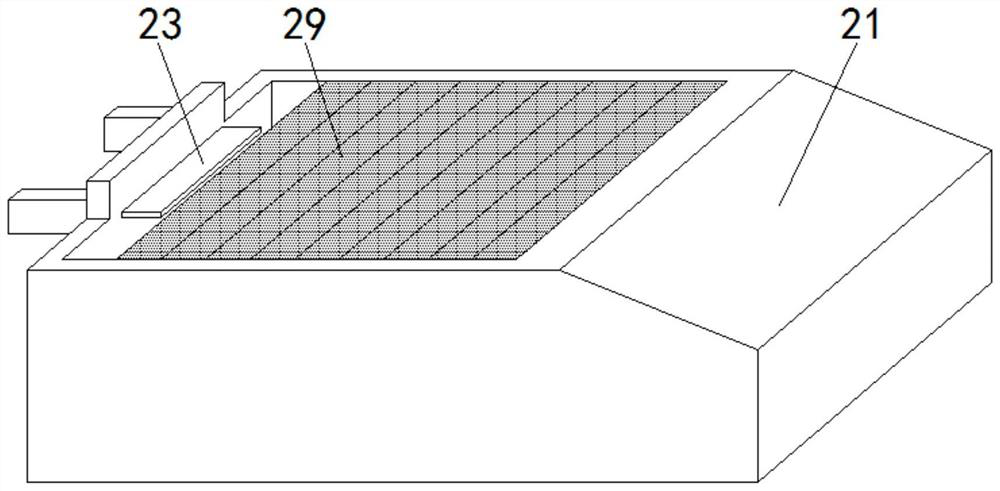

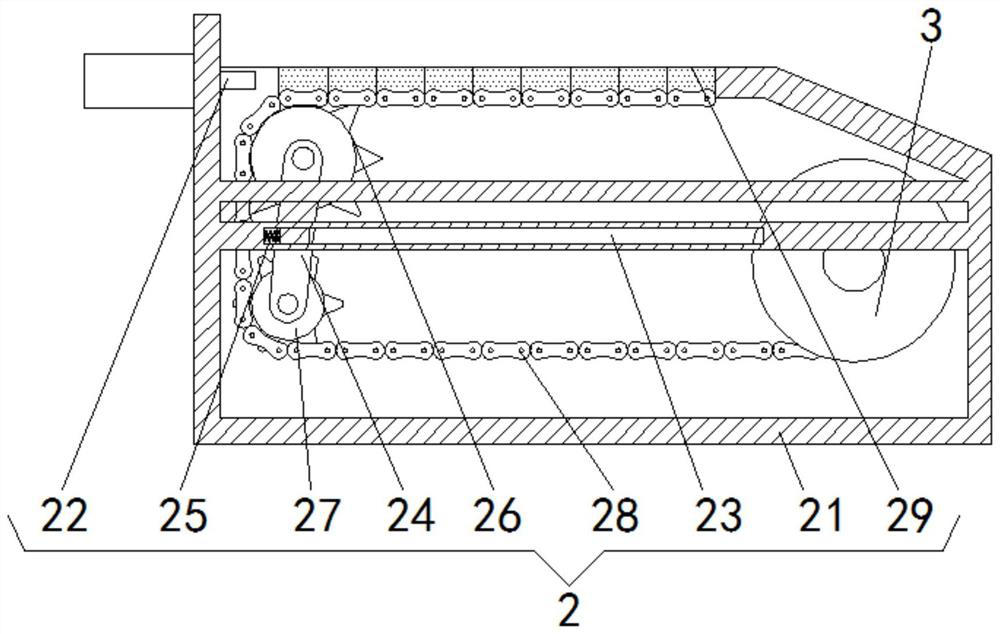

[0026] see Figure 1-Figure 6 , a 3D printing device using an artificial intelligence control system, including a printing mechanism 1, the printing mechanism 1 includes a printing shell 11, a printing assembly 12, a slide rail 13 and a slider 14, the slider 14 is used to fix the stage 21, print The inside of the mechanism 1 is equipped with an object-carrying mechanism 2, which includes a stage 21, a support plate 22 is inserted on the left side of the stage 21, and a support cylinder is fixedly connected to the left side of the support plate 22, and the support cylinder Fixedly connected to the left side of the stage 21, while the upper surface of the support plate 22 is lower than the upper surface of the bottom plate 29, so that the support plate 22 can stably move to the bottom of the product to support the product, and the interior of the stage 21 is fixed Be connected with guide rail 23, the inner sliding connection of guide rail 23 is connected with connecting rod 24, ...

Embodiment 2

[0029] see Figure 1-Figure 7, a 3D printing device using an artificial intelligence control system, including a printing mechanism 1, the printing mechanism 1 includes a printing shell 11, a printing assembly 12, a slide rail 13 and a slider 14, the slider 14 is used to fix the stage 21, print The inside of the mechanism 1 is equipped with an object-carrying mechanism 2, which includes a stage 21, a support plate 22 is inserted on the left side of the stage 21, and a support cylinder is fixedly connected to the left side of the support plate 22, and the support cylinder Fixedly connected to the left side of the stage 21, while the upper surface of the support plate 22 is lower than the upper surface of the bottom plate 29, so that the support plate 22 can stably move to the bottom of the product to support the product, and the interior of the stage 21 is fixed Be connected with guide rail 23, the inner sliding connection of guide rail 23 is connected with connecting rod 24, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com