Multifunctional traction tray for road train

A road train, multi-functional technology, applied in traction connectors, vehicle parts, transportation and packaging, etc., can solve the problems of inability to meet the requirements of fast drop and hook, fast parking, short turning radius of rear trailers, inability to tow trailers, etc. The effect of avoiding trailer falling off accidents, eliminating potential transportation hazards and reducing traffic accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

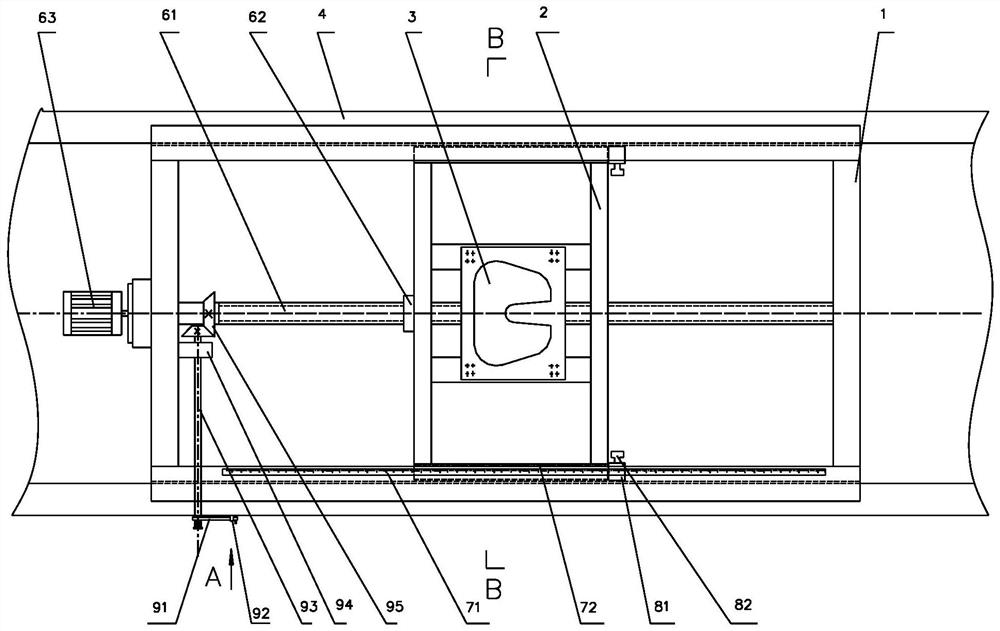

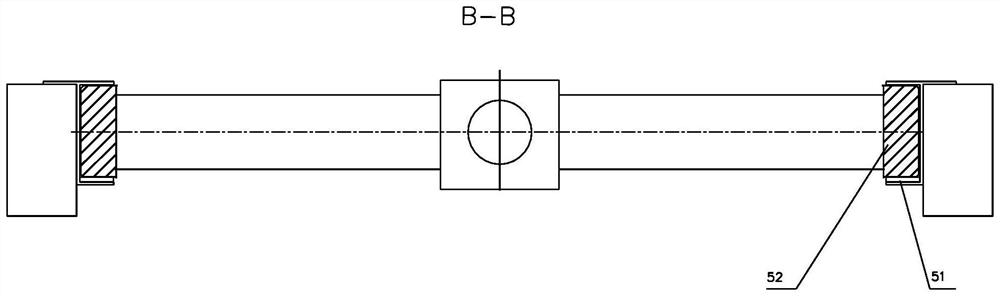

[0027] Such as Figure 2-6 As shown, a road train multifunctional traction pallet includes a main fixed bracket 1, an inner slide rail bracket 2, a traction disc 3, a slide rail assembly, a screw screw assembly, a scale assembly, a locking device and an alarm device.

[0028] The main fixing bracket 1 is a rectangular steel structure frame welded by I-beam or special-shaped I-beam. The main fixing bracket 1 is used to support the trailer load and the huge traction force of the tractor, and the steel needs to select special steel for the automobile frame.

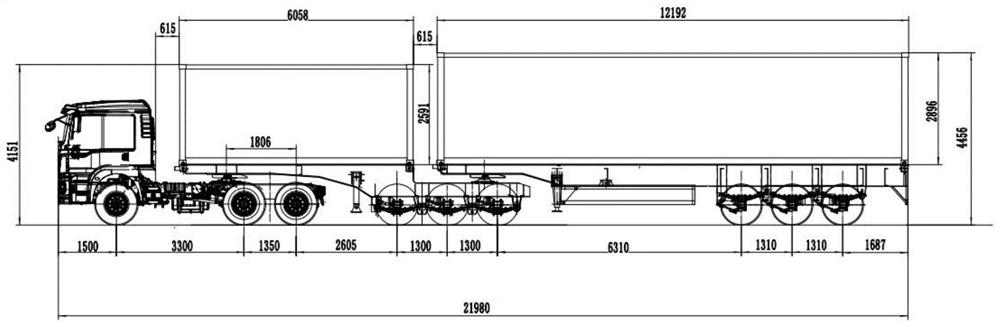

[0029] The main fixed bracket 1 and the tractor beam 1 are bolted together, the length is about 2000mm, and the vertical load is not less than 30 tons. The main fixed bracket 1 is embedded between the two tractor beams 4, and the width is equal to the distance between the tractor beams 4.

[0030]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com