Multi-station material carrying AGV trolley

A multi-station, material technology, applied in motor vehicles, transportation and packaging, etc., can solve the problems of inability to further improve production efficiency, difficult to spend on the number of AGV trolleys, idle waiting for trolleys, etc., to increase practicability and reduce car body damage. , The effect of placing the goods firmly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

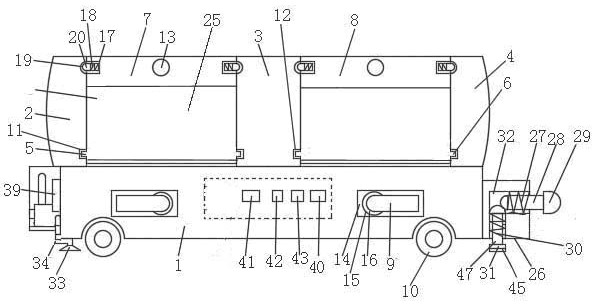

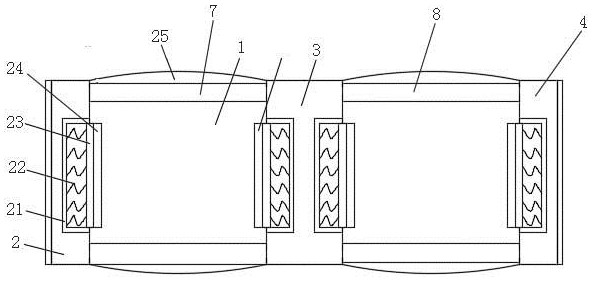

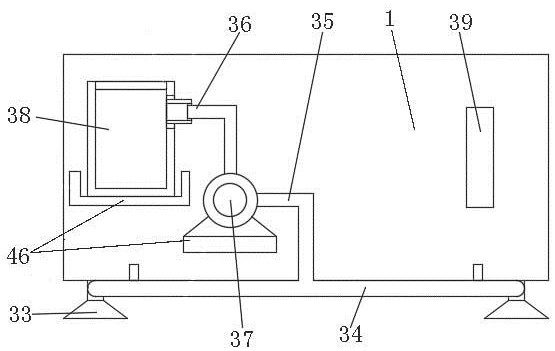

[0045] Such as Figure 1-3 As shown, the multi-station material handling AGV trolley includes a seat 1, a front vertical board 2, a middle vertical board 3, a rear vertical board 4, a rotating rod I5, a rotating rod II6, a baffle I7, a baffle II8, Support rod 9, sliding shaft 16;

[0046] The four corners of the bottom of the vehicle seat 1 are respectively provided with omnidirectional wheels 10 with planetary gear motors; Plate 4, on the top surface of the vehicle seat 1, is located in the middle of the front riser 2 and the rear riser 4 and is provided with a middle riser 3; the width of the front riser 2, the middle riser 3, and the rear riser 4 is the same 1 The width of the top surface is consistent;

[0047] The left and right sides of the bottom of the front vertical plate 2 and the middle vertical plate 3 are respectively provided with a rotating rod I5 through the rotating groove I11, the axial direction of the rotating rod I5 is parallel to the longitudinal direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com