Gas and powder mixed conveying equipment

A powder and gas technology, applied in the direction of conveyors, conveying bulk materials, transportation and packaging, etc., can solve problems such as prone to backwind, uneven mixing of powder and gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

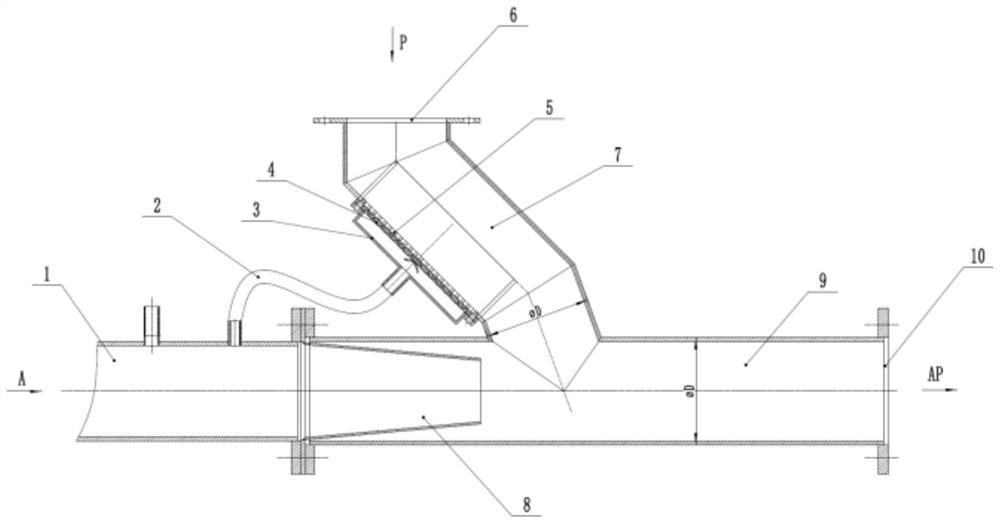

[0027] refer to figure 1 , the present invention provides a kind of equipment that mixes and transports gas and powder, which sequentially includes an air intake pipe 1, a vent pipe 2, an inflatable box 3, a ventilation device 4, a fluidized plate 5, a feed port 6, a fluidized box 7, Shrinking nozzle 8, feeding pipe 9, discharge port 10; wherein said air inlet duct 1 is connected with feeding pipe 9, and the junction of inlet air pipe 1 and feeding pipe 9 is provided with shrinking nozzle 8, and The mouth nozzle 8 faces the feeding pipe 9 direction, and its caliber gradually decreases; the right side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com