Carbon-based/metal composite material and preparation method thereof

A metal composite material and composite material technology are applied in the field of carbon-based/metal composite materials and their preparation, which can solve the problems of difficulty in obtaining single-atom or atomic cluster structures, aggregation and growth, etc., and achieve the effect of overcoming structural collapse and being easy to achieve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

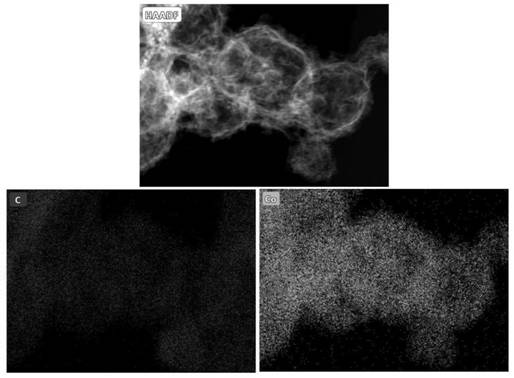

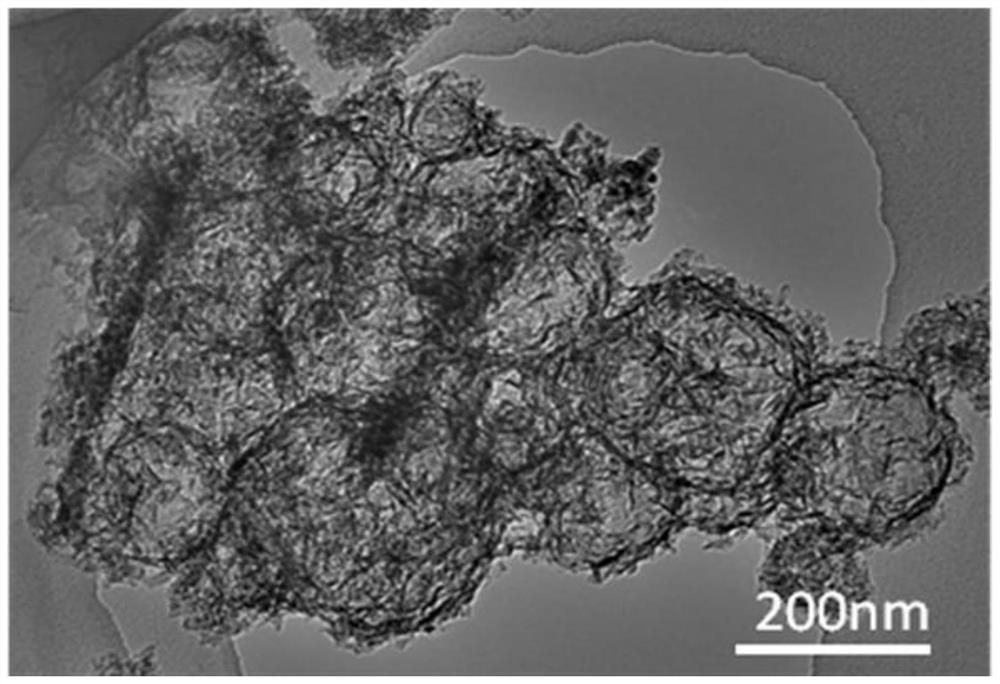

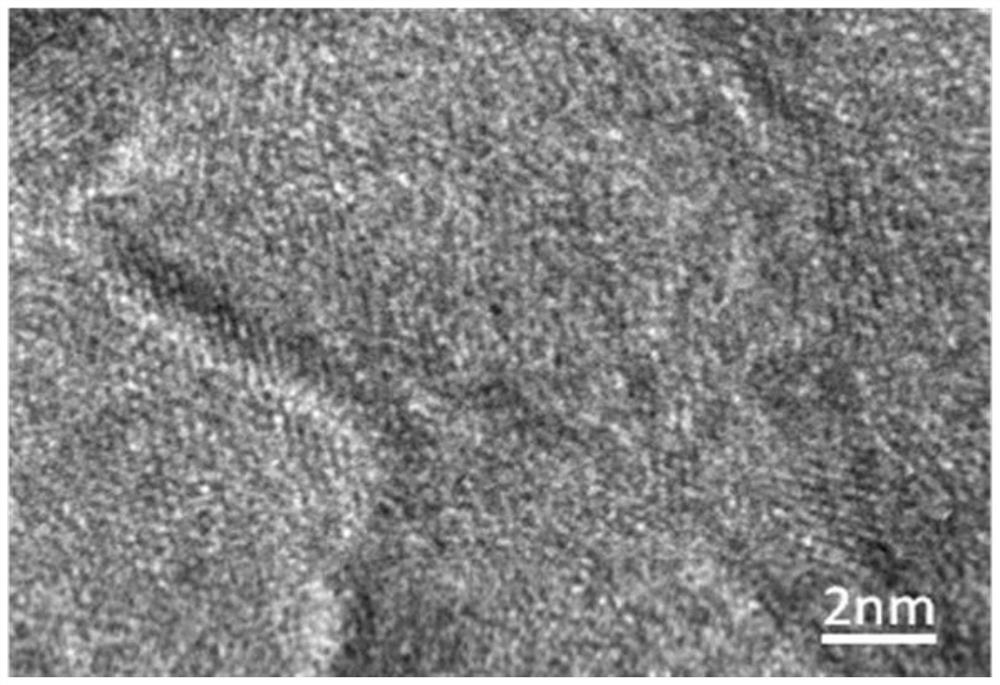

[0024] A preparation method of a carbon-based / metal composite material, comprising: preparing potassium as an alkali metal, using ZIF-67 (Chemical Engineering Journal 289(2016) 59-64.) as a metal framework material, and combining the alkali metal and the metal framework The materials are mixed in a quartz tube, vacuumed, and the quartz tube is sealed. The quartz tube is placed in a muffle furnace to heat up to 300 °C, the heating rate is 5 °C / min, and the temperature is kept for 24 hours. Cool down to room temperature of 20-25 °C with the furnace, and take it out. , broken the quartz tube, quenched with methanol, and suction filtered to obtain a carbon-based / metal composite material, wherein, in parts by mass, the ratio of alkali metal to metal framework material is 4:1.

[0025] Therein, the temperature is raised to 300°C so that the alkali metal forms potassium vapor and acts as a reducing agent.

[0026] In the above-mentioned technical scheme, quenching with methanol is du...

Embodiment 2

[0032] A preparation method of a carbon-based / metal composite material, comprising: preparing potassium as an alkali metal, using ZIF-8 (Chemical Communications 47(7)(2011) 2071-2073.) as a metal framework material, using alkali metal and metal The framework material is mixed in a quartz tube, evacuated, and the quartz tube is sealed. The quartz tube is placed in a muffle furnace to heat up to 360 °C, the heating rate is 5 °C / min, the temperature is kept for 24 hours, and the furnace is cooled to room temperature 20-25 °C , take out, break the quartz tube, quench with methanol, and filter with suction to obtain a carbon-based / metal composite material, wherein, in parts by mass, the ratio of alkali metal to metal framework material is 4:1.

[0033] Therein, the temperature is raised to 360° C. so that the alkali metal forms potassium vapor and acts as a reducing agent.

[0034] Compared with ZIF-8, the structure of carbon-based / metal composites observed by transmission electron...

Embodiment 3

[0036] A method for preparing a carbon-based / metal composite material, comprising: preparing potassium as an alkali metal, using a ferric chloride-covalent framework material composite material as a metal framework material, and mixing the alkali metal and the metal framework material in a quartz tube, Vacuum, seal the quartz tube, place the quartz tube in a muffle furnace and heat up to 360 ° C, the heating rate is 5 ° C / min, keep the temperature for 24 hours, cool down to room temperature 20-25 ° C with the furnace, take out, break the quartz tube, Quenching with methanol and suction filtration to obtain a carbon-based / metal composite material, wherein, in parts by mass, the ratio of alkali metal to metal framework material is 4:1.

[0037] Therein, the temperature is raised to 360° C. so that the alkali metal forms potassium vapor and acts as a reducing agent.

[0038] The preparation method of the ferric chloride-covalent framework material composite material is as follows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com