Preparation method of phenolic resin-based oxygen-doped microporous carbon electrode material

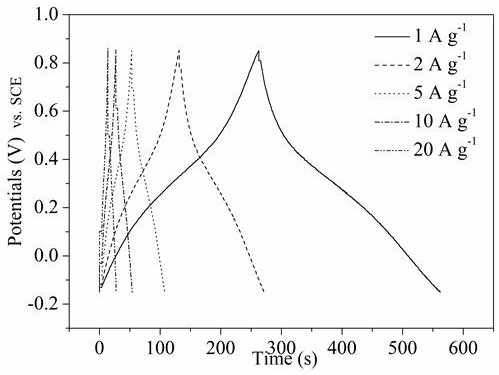

A technology of phenolic resin and electrode materials, applied in chemical instruments and methods, hybrid capacitor electrodes, carbon compounds, etc., can solve the problems of heteroatom loss, reduce doping rate, and reduce pseudocapacitive capacity, etc., to achieve high pseudocapacitive performance, The effect of high oxygen doping ratio and good rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

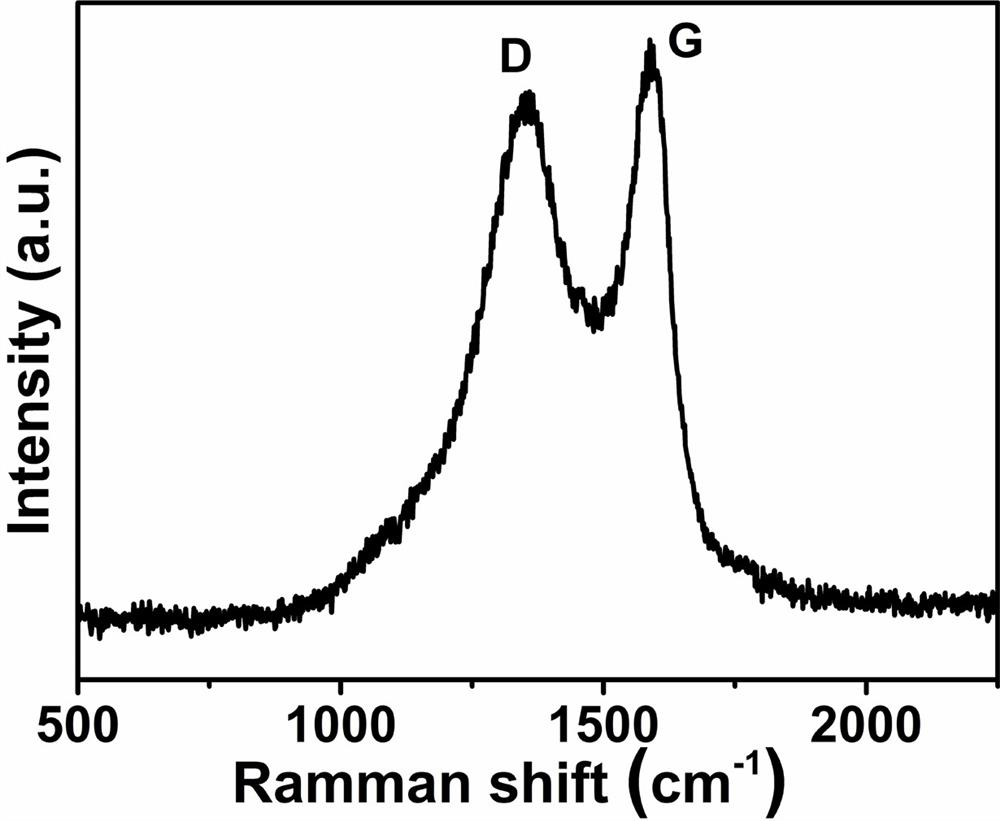

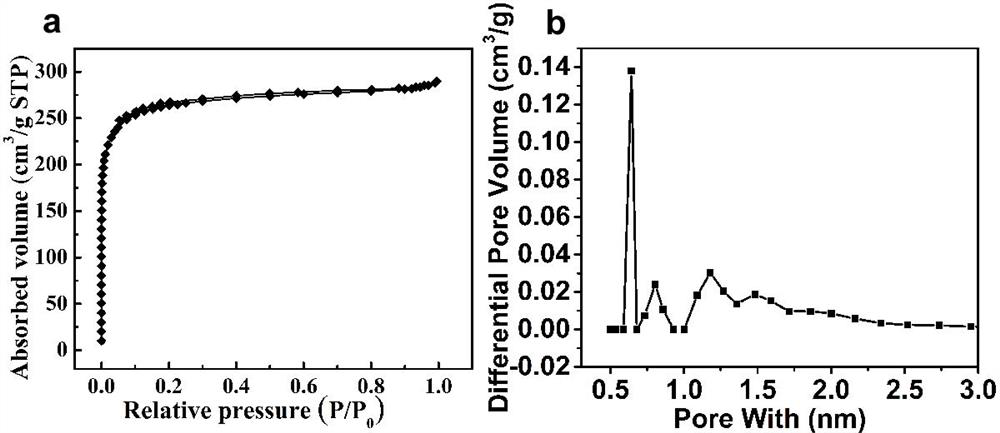

[0028] The preparation method of phenolic resin-based oxygen-doped microporous carbon electrode material is to stir 3-fluorophenol and hexamethylenetetramine at room temperature, then hydrothermally polymerize to obtain fluorophenolic resin, wash and dry, carbonize, and alkalinize Inorganic activation, pickling, washing and drying in the system.

[0029] Specific steps are as follows:

[0030] A. Dissolve 3-fluorophenol and hexamethylenetetramine in 80 mL of distilled water according to a certain mass ratio to form a mixed solution, and stir at room temperature for a period of time;

[0031] B. Transfer the stirred mixed solution to a 100 mL reaction kettle, carry out hydrothermal reaction at a certain temperature to obtain a solid product, wash the solid product with water to pH=7, 60 o Drying under C for 12 hours obtained the fluorophenolic resin microspheres;

[0032] C, the fluorinated phenolic resin microsphere that step B makes is heat-treated for a period of time in n...

Embodiment 1

[0039] 0.2 g of 3-fluorophenol and 0.1 g of hexamethylenetetramine were weighed and dissolved in 80 mL of distilled water, and stirred at room temperature for 1 h until the solid sample was completely dissolved. Then, the solution was transferred to a 100 mL reactor, reacted at 160°C for 4 hours, the product was washed to pH=7, and dried at 60°C for 12 hours to obtain fluorophenolic resin microspheres.

[0040] The above sample was heated from room temperature to 500°C under the protection of nitrogen, and kept for 4 hours. After naturally cooling to room temperature, the above-mentioned carbonized sample was ground and mixed with the activator KOH at a mass ratio of 1 / 6, and the mixed sample was heated from room temperature to 500°C in a nitrogen atmosphere and kept for 8 hours. Naturally cooled to room temperature, the solid sample was washed with hydrochloric acid solution and water to pH = 7, and after drying, a phenolic resin-based oxygen-doped microporous carbon electrod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com